Method for extracting valuable elements from waste denitration catalysts by virtue of medium-temperature tunnel type solid-state activation

A technology for waste denitration catalyst and denitration waste catalyst, which is applied in the direction of improving process efficiency, can solve the problems of high recovery energy consumption, air pollution, and increase of waste gas treatment devices, and achieves fine separation and recovery process, low energy consumption, and process environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

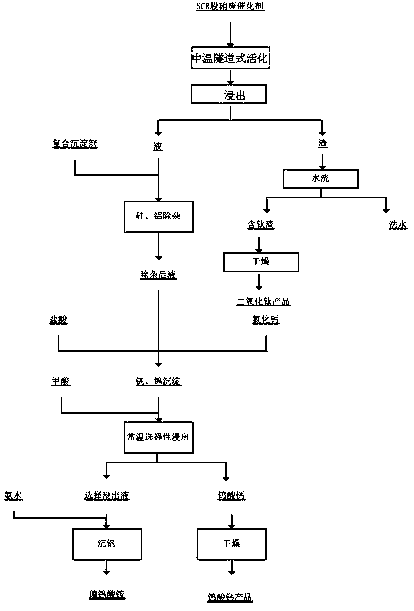

Image

Examples

Embodiment 1

[0021] The raw material comes from a power plant in Guizhou SCR denitrification waste catalyst, in which the content of titanium oxide is 86.2%, the content of vanadium pentoxide is 0.47%, and the content of tungstic acid is 3.72%. The catalyst is crushed to 80 mesh > 98%, mixed evenly with 20% sodium carbonate and 3% sodium-based double salt, extruded, sent to a tunnel-type activation reactor for activation for 2 hours, and passed through a preheating zone at 200°C , The activation reaction zone is 650°C, and the cooling zone is 90°C. Send the activated material to a high-speed disperser with water for water extraction first, then disperse and disperse the material at a high speed, and pump it to a high-efficiency leaching tank under a state of uniform stirring. 3:1 stirring reaction for 2 hours, after the reaction leaching is completed, after liquid-solid separation, the leach residue is washed and dried to obtain a titanium oxide product with a purity of 95.5%; the leaching...

Embodiment 2

[0023] The raw material comes from a power plant in Guizhou SCR denitrification waste catalyst, in which the content of titanium oxide is 85.2%, the content of vanadium pentoxide is 0.57%, and the content of tungstic acid is 3.92%. The catalyst is crushed to 80 mesh > 98%, mixed evenly with 15% sodium carbonate and 1.5% sodium-based double salt, extruded, sent to a tunnel-type activation reactor for activation for 2 hours, and passed through a preheating zone at 200°C , The activation reaction zone is 700°C, and the cooling zone is 90°C. Send the activated material to a high-speed disperser with water for water extraction first, then disperse and break up the material at a high speed, and pump it to a high-efficiency leaching tank under a state of uniform stirring. 3:1 stirring reaction for 2 hours, after the reaction leaching is completed, after liquid-solid separation, the leach residue is washed and dried to obtain a titanium oxide product with a purity of 95.1%; the leachi...

Embodiment 3

[0025]The raw material comes from a power plant in Guizhou SCR denitrification waste catalyst, in which the content of titanium oxide is 87.2%, the content of vanadium pentoxide is 0.61%, and the content of tungstic acid is 3.82%. The catalyst is crushed to 80 mesh>98%, mixed evenly with 10% sodium carbonate and 2% sodium-based double salt, extruded, sent to a tunnel-type activation reactor for activation for 2 hours, and passed through a preheating zone at 200°C , The activation reaction zone is 750°C, and the cooling zone is 90°C. Send the activated material to a high-speed disperser with water for water extraction first, then disperse and disperse the material at a high speed, and pump it to a high-efficiency leaching tank under a state of uniform stirring. 3:1 stirring reaction for 2 hours, after the reaction leaching is completed, after liquid-solid separation, the leach residue is washed and dried to obtain a titanium oxide product with a purity of 95.5%; the leaching fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com