Preparation method of cesium lead bromide quantum dot/carbon nitride nanosheet photocatalyst

A lead cesium bromide quantum and photocatalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of easy recombination and poor stability of photogenerated electrons and holes, and achieve the preparation method Simple, good stability, the effect of overcoming instability and loss of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

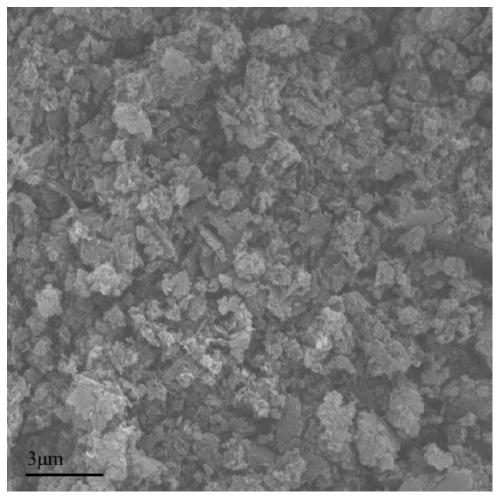

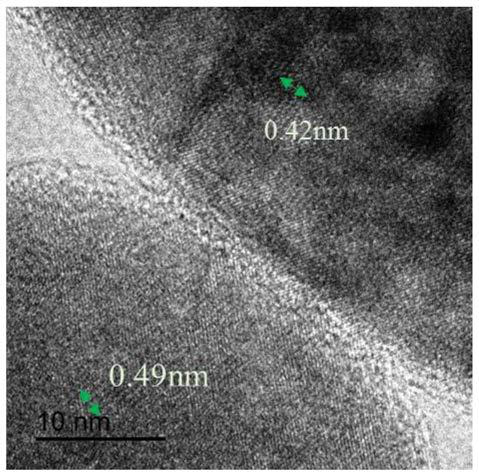

[0019] Specific embodiment one: This embodiment is the simple preparation of lead cesium bromide quantum dot / graphite phase carbon nitride nanosheet photocatalytic material, and the specific steps are as follows:

[0020] 1) Add 2.5 mmol of cesium carbonate to a three-necked flask containing 10.0 ml of 1-octadecene and 2.5 ml of oleic acid, and place in an oil bath at 120° C. for 1 h. Then, at N 2 The mixture was heated to 150 °C under atmosphere until the complete reaction between cesium carbonate and oleic acid to form a precursor solution. Add 2.0 mmol of lead bromide to a flask containing 10.0 ml of N,N-dimethylformamide, 4.0 mmol of hexanoic acid and 4.0 mmol of octylamine, stir the mixture until the lead bromide is dissolved, then add 2.5 ml of the above-prepared The precursor solution was stirred for 5 h, and finally the mixture was dispersed in 100 ml of toluene solution. Use ethanol as an anti-solvent, and add it into the above toluene solution at a volume ratio of ...

specific Embodiment 2

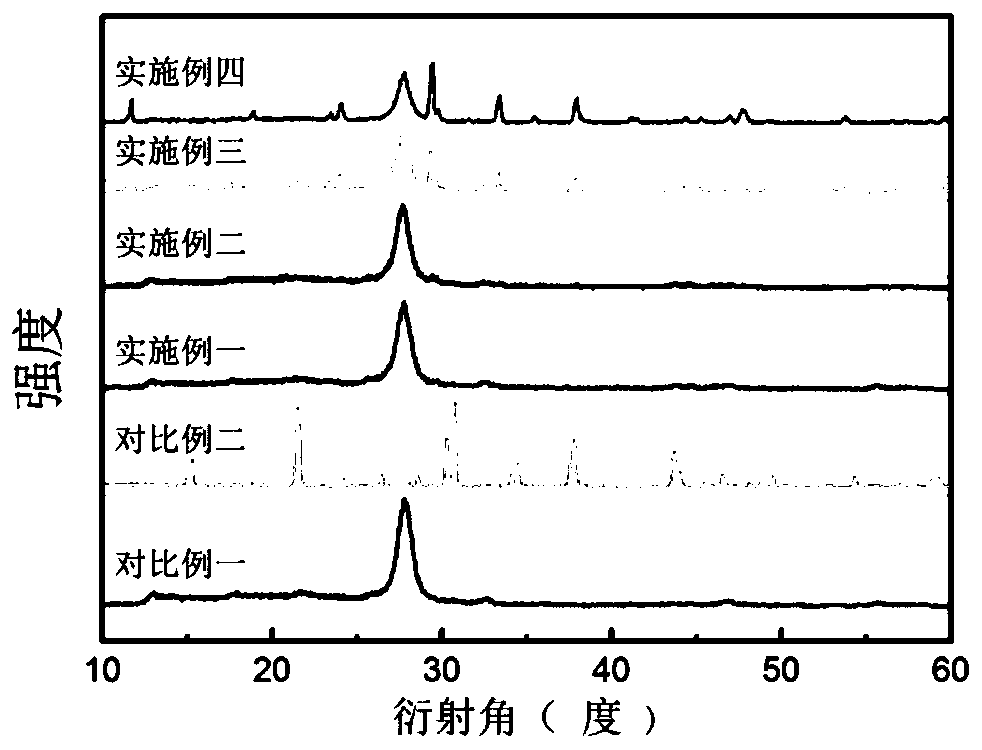

[0023] Specific embodiment 2: the difference between this embodiment and specific embodiment 1 is that the quality of lead cesium bromide quantum dots in step 4 is 0.05g, and the others are the same as specific embodiment 1.

specific Embodiment 3

[0024]Specific embodiment three: the difference between this embodiment and specific embodiment one is that the mass of lead cesium bromide quantum dots in step four is 0.10g, and the others are the same as specific embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com