A visible light catalytic permeable brick and its production method and application

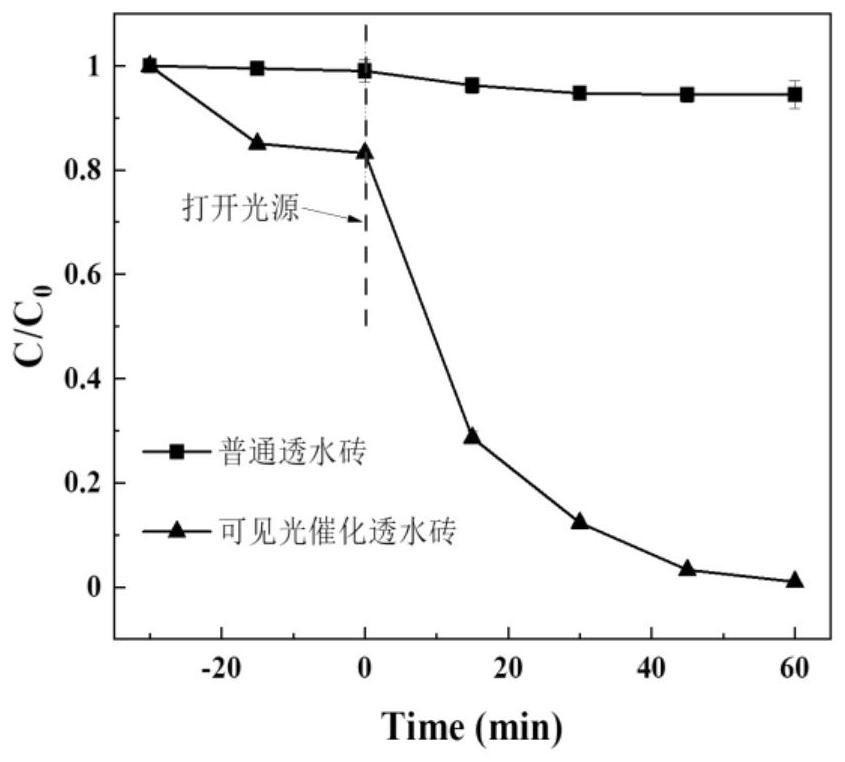

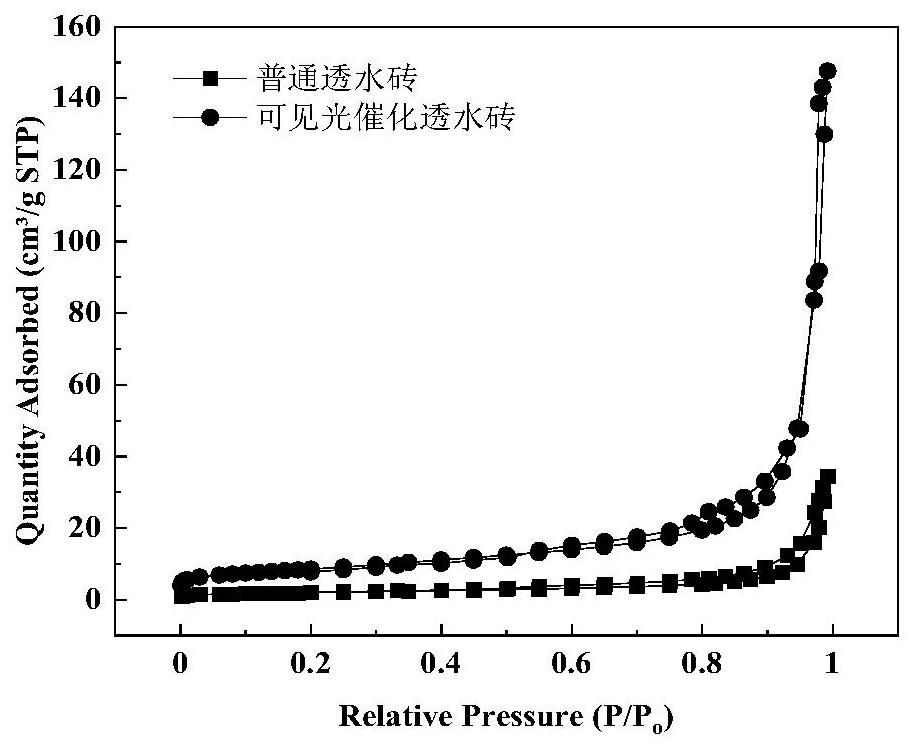

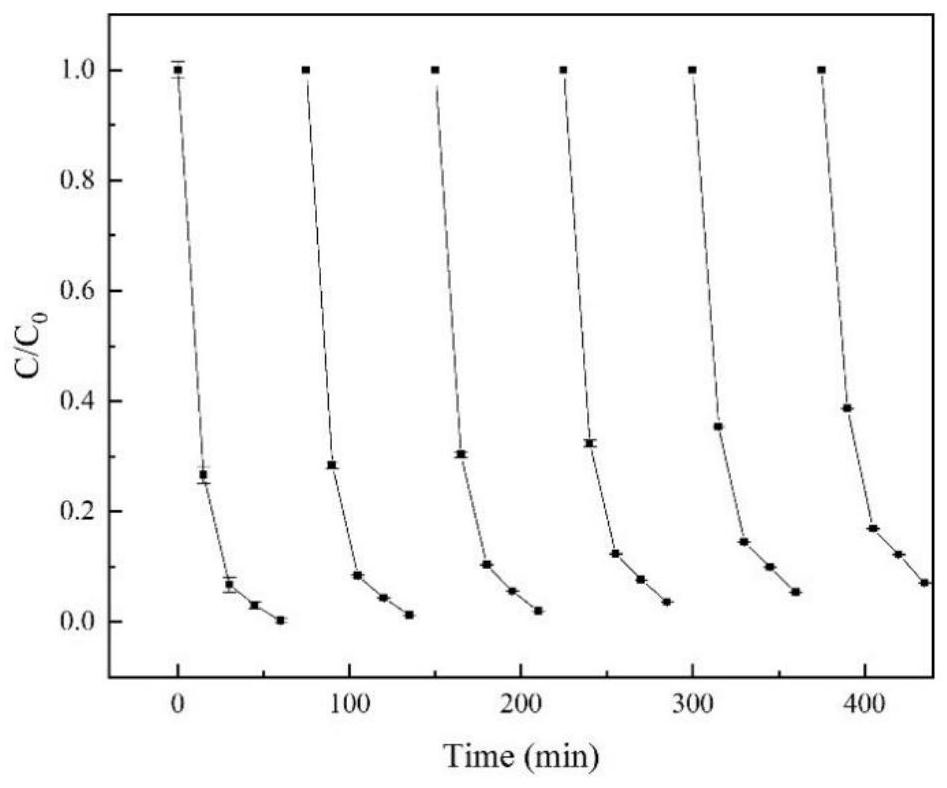

A visible light, permeable brick technology, applied in anti-fouling/underwater coatings, paving surfaces paved with prefabricated blocks, roads, etc., can solve problems such as unfavorable photo-generated carrier transport, low photoelectric conversion efficiency, and limited application effects. To achieve the effect of simple and easy-to-obtain raw materials, good sunlight absorption capacity and utilization rate, and conducive to popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a visible light catalyzed permeable brick is provided, and the specific steps are as follows:

[0041] (1) Preparation of g-C 3 N 4 : Put 5g of dicyandiamide in a beaker, add 150mL of deionized water, and then ultrasonically vibrate for 4h. After drying at 60 °C, the dicyandiamide was transferred into a crucible. Then put the crucible in a box-type energy-saving resistance furnace, set the temperature program for 4h, and then keep it at 550°C for 4h. After natural cooling, the resulting yellow substance was transferred into a mortar for grinding, then transferred into a beaker, and 150 mL of deionized water was added for ultrasonic vibration for 4 h. Finally, after drying at 50°C, g-C 3 N 4 .

[0042] (2) Preparation of Fe 2 o 3 / g -C 3 N 4 Visible light catalytic composite material: weigh 0.35g of FeSO 4 ·7H 2 O, and the g-C that 10g step (1) prepares 3 N 4 mix. The mixture was then placed in a deionized water / ethanol solution with...

Embodiment 2

[0054] A method for preparing a visible light catalyzed permeable brick is provided, and the specific steps are as follows:

[0055] (1) Preparation of g-C 3 N 4 : preparation method is with embodiment 1.

[0056] (2) Preparation of Fe 2 o 3 / g -C 3 N 4 Visible light catalytic composite material: weigh 1.05g of FeSO 4 ·7H 2 O, with 10g of g-C prepared in step (1) 3 N 4 Mix, other is identical with embodiment 1 preparation method, the last gained Fe 2 o 3 / g -C 3 N 4 In visible photocatalytic composite materials, Fe 2 o 3 The mass percentage content is 3%.

[0057] (3) Preparation of Fe 2 o 3 / g -C 3 N 4Visible light catalytic coating: the preparation method is the same as in Example 1.

[0058] (4) Fe prepared by step (3) 2 o 3 / g -C 3 N 4 Visible light catalytic coating, uniformly sprayed on the surface of the permeable brick substrate, to obtain Fe 2 o 3 / g -C 3 N 4 Composite coating with a thickness of 5 mm can obtain a visible light catalyzed pe...

Embodiment 3

[0061] A method for preparing a visible light catalyzed permeable brick is provided, and the specific steps are as follows:

[0062] (1) Preparation of g-C 3 N 4 : preparation method is with embodiment 1.

[0063] (2) Preparation of Fe 2 o 3 / g -C 3 N 4 Visible light catalytic composite material: weigh 1.75g of FeSO 4 ·7H 2 O, and the g-C that 10g step (1) prepares 3 N 4 Mix, other is identical with embodiment 1 method, the last gained Fe 2 o 3 / g -C 3 N 4 In visible photocatalytic composite materials, Fe 2 o 3 The mass percentage content is 5%.

[0064] (3) Preparation of Fe 2 o 3 / g -C 3 N 4 Visible light catalytic coating: the preparation method is the same as in Example 1.

[0065] (4) Fe prepared by step (3) 2 o 3 / g -C 3 N 4 Visible light catalytic coating, uniformly sprayed on the surface of the permeable brick substrate, to obtain Fe 2 o 3 / g -C 3 N 4 Composite coating with a thickness of 5 mm can obtain a visible light catalyzed permeable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com