Preparation method and application of layered bismuth oxychloride visible light catalyst

A technology based on bismuth oxychloride and visible light, applied in the field of visible light catalysis, can solve problems such as limited application and great difficulty, achieve broad application prospects, reduce agglomeration, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

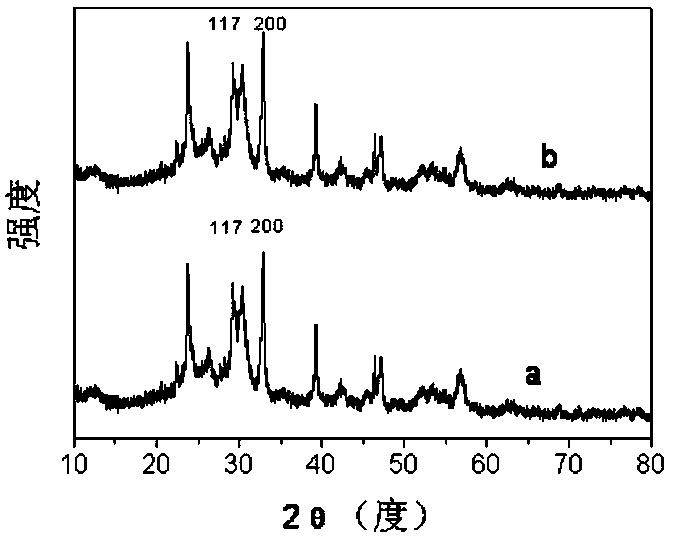

[0023] A kind of preparation method of layered bismuth oxychloride visible light catalyst of the present invention comprises the following steps: 2g Bi(NO 3 ) 3 ·5H 2 O and 0.02g of polyvinylpyrrolidone were added to 20mL of ethylene glycol, stirred for 10min using a magnetic stirrer, and simultaneously assisted by ultrasonic treatment to obtain phase A; 0.65g of NH 4 Cl and 1.95g NaOH were added into 120mL water and stirred for 3min to obtain phase B. Phase A and Phase B are mixed and then transferred to a hydrothermal reactor with polytetrafluoroethylene and heated at 140°C for 12h. After naturally cooling to room temperature, the resulting yellow powder was collected by filtration and washed three times with distilled water and absolute ethanol to remove residual ions and organic matter, and then the product was dried at 80 °C for 6 h to obtain layered bismuth oxychloride Bi 12 o 17 Cl 2 Visible light catalyst, bismuth oxychloride can also be called bismuth oxychloride...

Embodiment 2

[0025] A kind of preparation method of layered bismuth oxychloride visible light catalyst of the present invention comprises the following steps: 2g Bi(NO 3 ) 3 ·5H 2 O and 0.02g of polyvinylpyrrolidone were added to 20mL of ethylene glycol, stirred for 10min using a magnetic stirrer, and simultaneously assisted by ultrasonic treatment to obtain phase A; 0.65g of NH 4 Cl and 1.95g NaOH were added into 120mL water and stirred for 3min to obtain phase B. Phase A and Phase B are mixed and then transferred to a hydrothermal reactor with polytetrafluoroethylene and heated at 160°C for 12h. After naturally cooling to room temperature, the resulting yellow powder was collected by filtration and washed three times with distilled water and absolute ethanol to remove residual ions and organic matter, and then the product was dried at 80 °C for 6 h. layered bismuth oxychloride Bi 12 o 17 Cl 2 Visible light catalyst, the obtained product is a yellow flaky solid, which turns into a d...

Embodiment 3

[0029] Embodiment 3: Catalyst degrades tetracycline under visible light

[0030] An application of the layered bismuth oxychloride visible light catalyst prepared by the preparation method of the layered bismuth oxychloride visible light catalyst in degrading organic pollutant wastewater. With tetracycline as characteristic pollutant, the catalyst that is obtained by the preparation method of embodiment 1 and embodiment 2 carries out degradation experiment respectively, and wherein the concentration of tetracycline solution is 20mg / L; Get catalyst 100mg, be placed in the above-mentioned tetracycline-containing aqueous solution of 100ml .

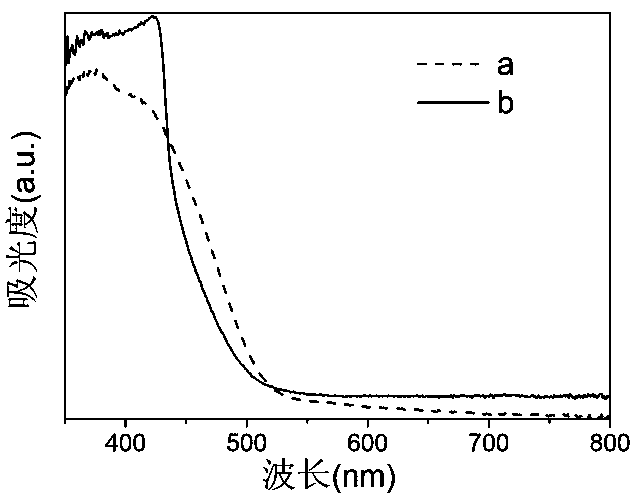

[0031] In the solution, stir in a dark room for 60 minutes, then place the solution in a 300W (greater than 420nm) visible light source, irradiate for 1 hour, take 3ml tetracycline solution every 10 minutes, measure the concentration of tetracycline in the solution with UV-vis, and calculate the degradation rate. From Figure 4 a It can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com