Low-temperature high-energy-density long-cycle lithium iron phosphate battery

A lithium iron phosphate battery, high energy density technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems that the use temperature is difficult to break through, limit the promotion of use, and the use environment is difficult, so as to improve stability and Cyclic, improve the overall stability, improve the effect of its own anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

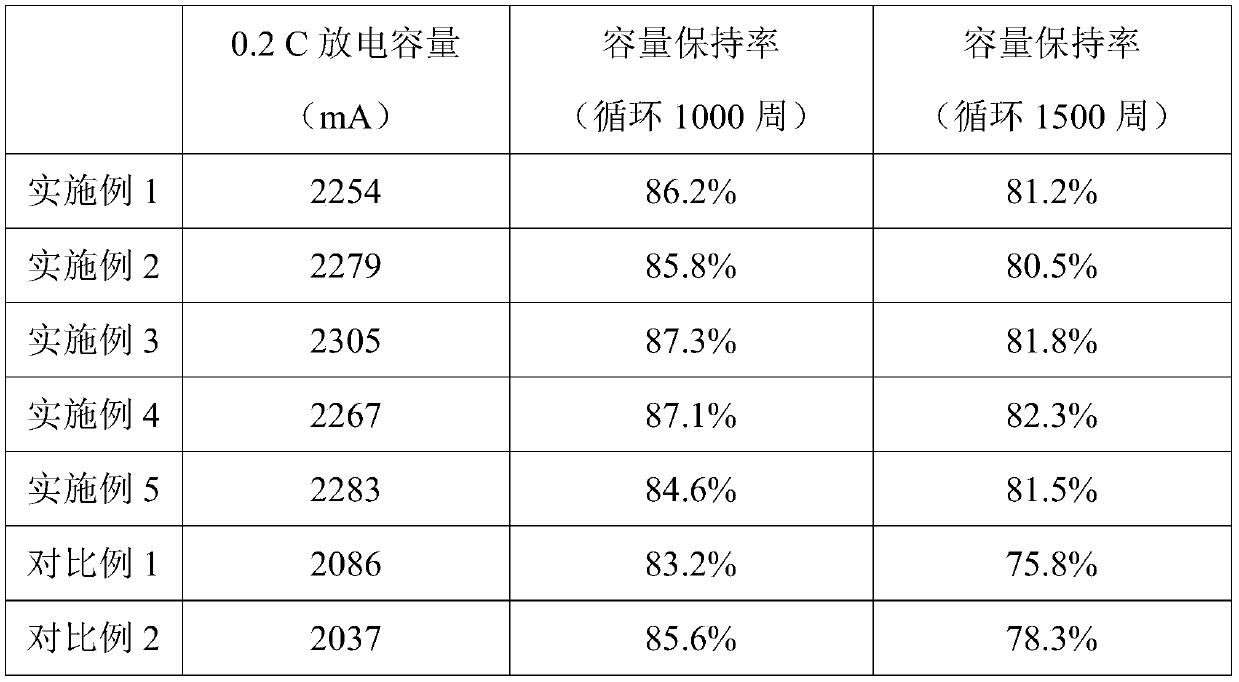

Embodiment 1

[0050] A low-temperature, high-energy density, long-cycle lithium iron phosphate battery, including a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte and a casing; wherein the positive electrode sheet is uniformly coated with a mixture of positive electrode active material, conductive agent and binder Made on both sides of 1.5μm metal aluminum foil, roll thickness is 148μm, roll compaction density is 2.35g / cm 3 , The slitting width is 58mm; the negative electrode sheet is made by uniformly coating a mixture of negative electrode active material, conductive agent and binder on both sides of a 5μm metal copper foil. The rolling thickness is 148μm, and the compaction density is 2.2 g / cm 3 , The slitting width is 58mm. The produced battery weighs 40.16g.

[0051] The positive electrode active material is doped lithium iron phosphate, with an average particle size of 1.5um, of which D50 is 1.5um, D90 is 5um, doped materials are 10wt% hexagonal boron n...

Embodiment 2

[0054] A low-temperature, high-energy density, long-cycle lithium iron phosphate battery, including a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte and a casing; wherein the positive electrode sheet is uniformly coated with a mixture of positive electrode active material, conductive agent and binder It is made on both sides of 2μm metal aluminum foil, the rolling thickness is 147μm, and the rolling density is 2.3g / cm 3 , The slitting width is 59mm; the negative electrode sheet is made by uniformly coating the mixture of the negative electrode active material, the conductive agent and the binder on both sides of the 6.5μm metal copper foil, the rolling thickness is 149μm, and the rolling compaction density 2.3g / cm 3 , The slitting width is 59mm. The produced battery weighs 40.43g.

[0055] The positive electrode active material is doped lithium iron phosphate, with an average particle size of 2.5um, of which D50 is 3um, D90 is 7um, doped materia...

Embodiment 3

[0058] A low-temperature, high-energy density, long-cycle lithium iron phosphate battery, comprising a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte and a casing; wherein the positive electrode sheet is uniformly coated with a mixture of positive electrode active material, conductive agent and binder It is made on both sides of 3.5μm metal aluminum foil with a rolling thickness of 150μm and a rolling density of 2.45g / cm 3 , The slitting width is 58.5mm; the negative electrode sheet is made by uniformly coating a mixture of negative active material, conductive agent and binder on both sides of a 6μm metal copper foil. The rolling thickness is 150μm, and the compaction density is rolled. 2.33g / cm 3 , The slitting width is 58.5mm. The weight of the prepared battery is 39.81g.

[0059] The positive electrode active material is doped lithium iron phosphate, with an average particle size of 3.5um, where D50 is 4um, D90 is 6um, the doping material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com