A sulfide ion-modified sno 2 base low temperature so 2 Sensitive material and preparation method thereof

A sensitive material, SO2 technology, applied in the direction of material resistance, material analysis, material analysis by electromagnetic means, etc., can solve the problem that the shape and particle size of tin disulfide cannot be well controlled, and achieve small particle size, resistance Reduced, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

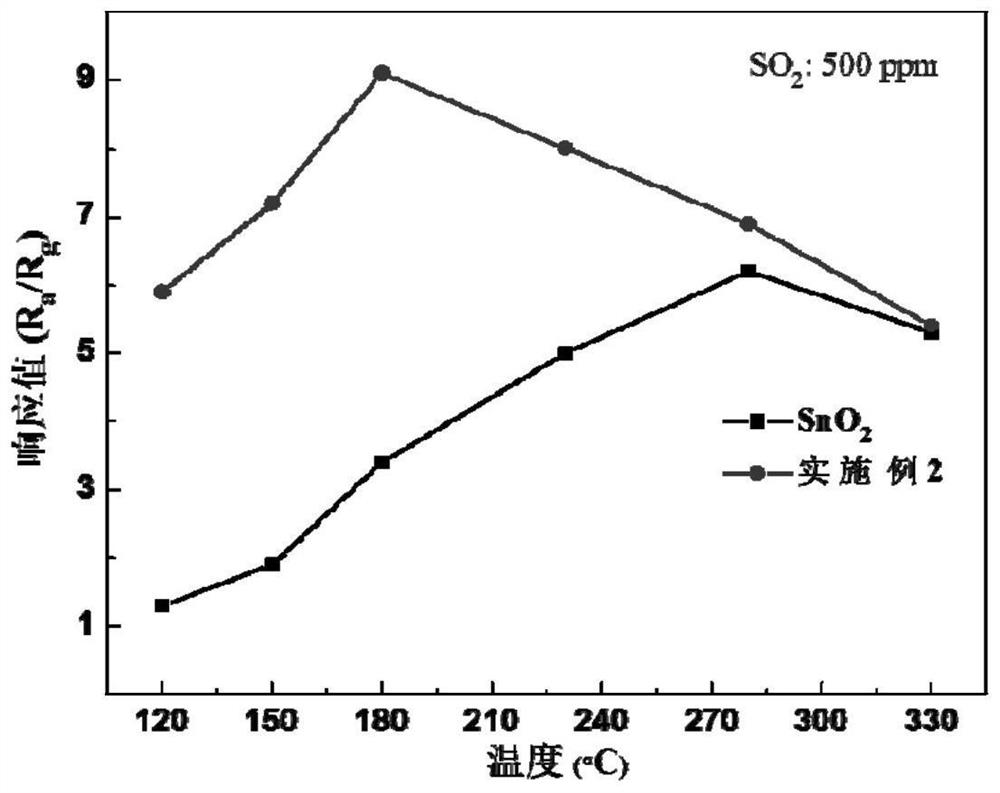

[0035] SnO surface modified by sulfide ion 2 low temperature SO 2 gas sensor

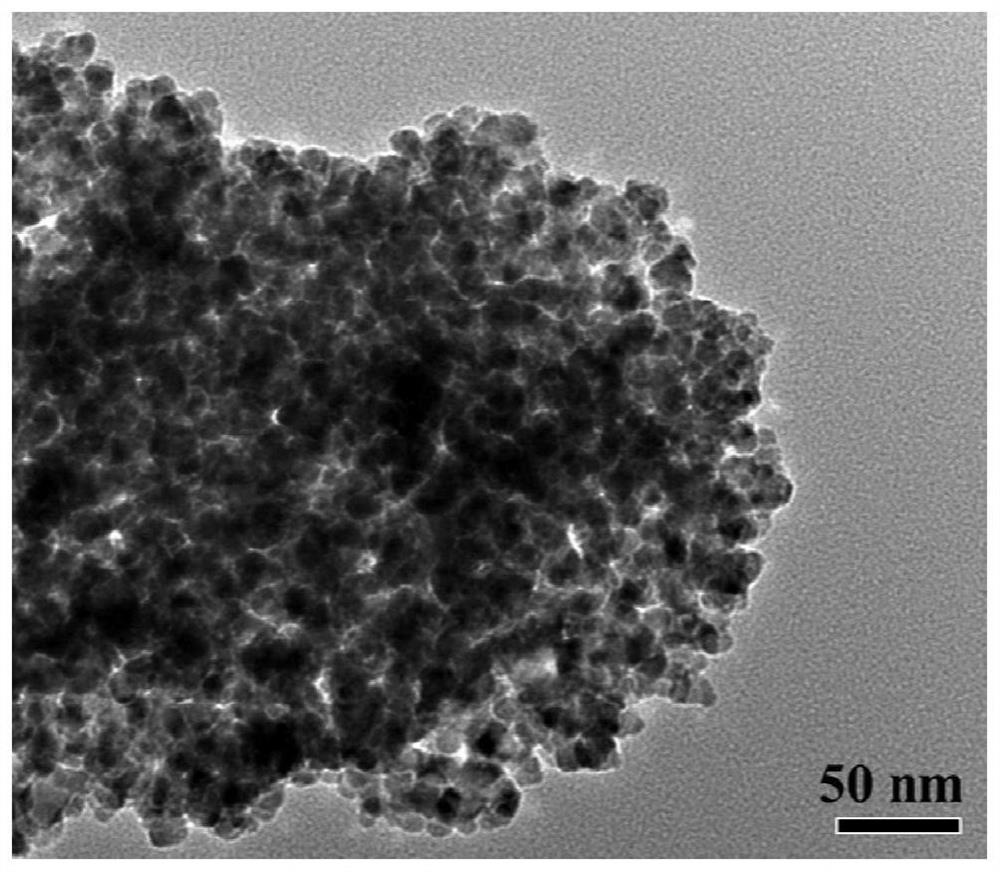

[0036] SnCl 4 ·5H 2 O, ethylenediaminetetraacetic acid and deionized water are mixed in a mass ratio of 1:0.1:15, wherein SnCl 4 ·5H 2 O is added in an amount of 10 g. Under the condition of magnetic stirring and water bath at 70°C, ammonia water was added dropwise until the solution pH=5. After the solution was cooled and left still, the precipitate was separated, washed and dried, and oxidized and roasted at 500°C for 3 hours to obtain SnO 2 nanomaterials; the SnO 2 Nanoparticles, glacial acetic acid, and thioacetamide were added to 80 g of deionized water in a mass ratio of 1:4:8, wherein SnO 2 The amount of nanoparticles added was 1 g, and after magnetic stirring for 30 min, the mixture was sealed and reacted at a constant temperature of 160° C. for 15 h. Then the precipitate was separated, washed and dried to obtain the SnO surface modified by sulfide ion 2 Base SO 2 Sensitive materi...

Embodiment 2

[0038] SnO surface modified by sulfide ion 2 low temperature SO 2 gas sensor

[0039] SnCl 4 ·5H 2 O, ethylenediaminetetraacetic acid and deionized water are mixed in a mass ratio of 1:0.2:15, wherein SnCl 4 ·5H 2 O is added in an amount of 10 g. Under the condition of magnetic stirring and water bath at 70°C, ammonia water was added dropwise until the solution pH=5. After the solution was cooled and left still, the precipitate was separated, washed and dried, and oxidized and roasted at 500°C for 3 hours to obtain SnO 2 nanomaterials; the SnO 2 Nanoparticles, glacial acetic acid, and thioacetamide were added to 80 g of deionized water in a mass ratio of 1:4:8, wherein SnO 2 The amount of nanoparticles added was 1 g, and after magnetic stirring for 30 min, the mixture was sealed and reacted at a constant temperature of 160° C. for 15 h. Then the precipitate was separated, washed and dried to obtain the SnO surface modified by sulfide ion 2 Base SO 2 Sensitive materi...

Embodiment 3

[0043] SnO surface modified by sulfide ion 2 low temperature SO 2 gas sensor

[0044] SnCl 4 ·5H 2 O, ethylenediaminetetraacetic acid and deionized water are mixed in a mass ratio of 1:0.3:15, wherein SnCl 4 ·5H 2 O is added in an amount of 10 g. Under the condition of magnetic stirring and water bath at 70°C, ammonia water was added dropwise until the solution pH=5. After the solution was cooled and left still, the precipitate was separated, washed and dried, and oxidized and roasted at 500°C for 3 hours to obtain SnO 2 nanomaterials; the SnO 2 Nanoparticles, glacial acetic acid, and thioacetamide were added to 80 g of deionized water in a mass ratio of 1:4:8, wherein SnO 2 The amount of nanoparticles added was 1 g, and after magnetic stirring for 30 min, the mixture was sealed and reacted at a constant temperature of 160° C. for 15 h. Then the precipitate was separated, washed and dried to obtain the SnO surface modified by sulfide ion 2 Base SO 2 Sensitive materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com