Cerium-zirconium composite oxide with high specific surface area, and preparation method and application thereof

A composite oxide and specific surface area technology, which is used in the field of cerium-zirconium solid solution with high specific surface area and its preparation, can solve the problems that the performance cannot meet the requirements of emission regulations, the cerium-zirconium composite oxide has large crystal grains and weak anti-aging ability, etc. Achieve the effects of large pore volume, good low-temperature catalytic activity, and high oxygen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

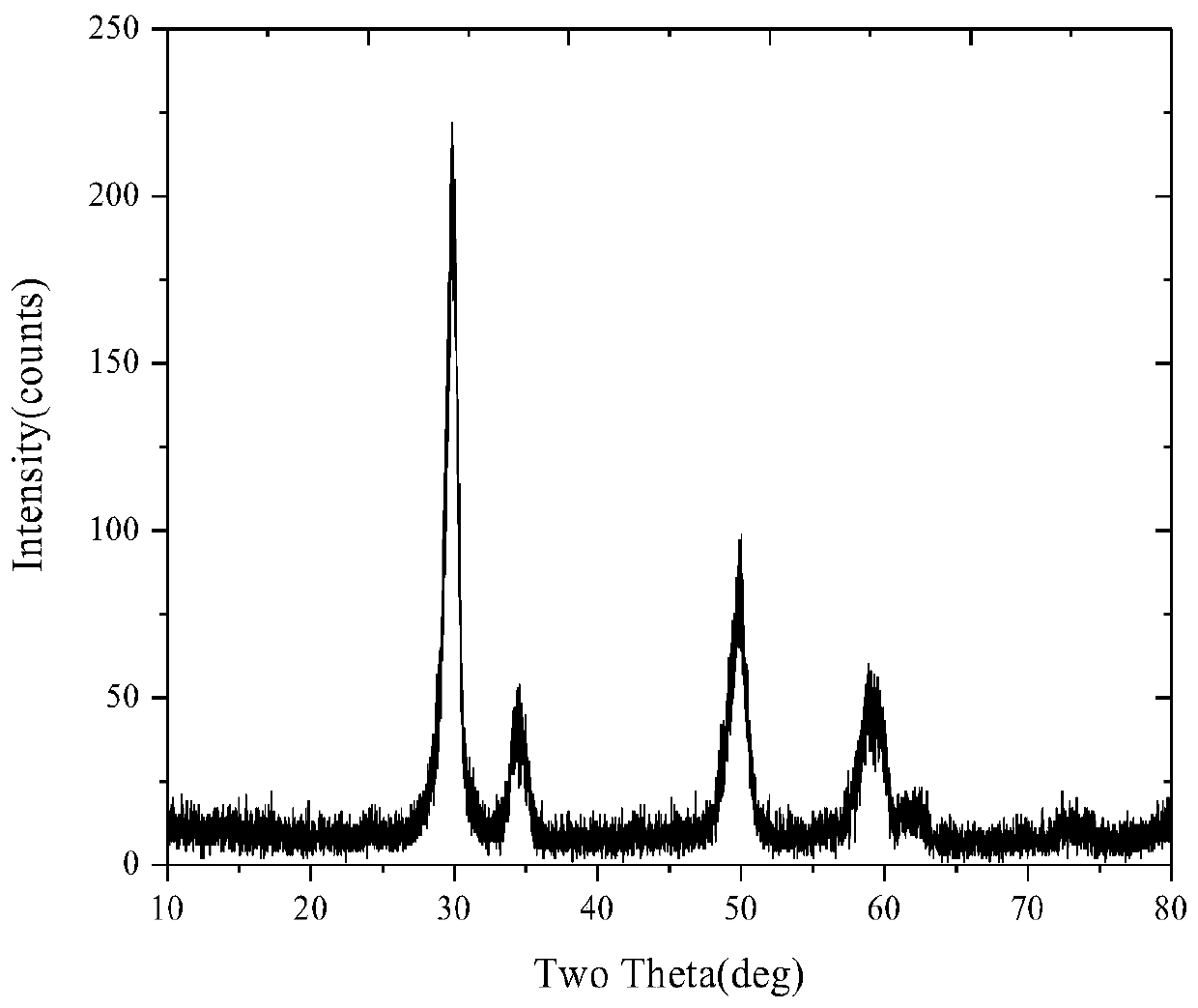

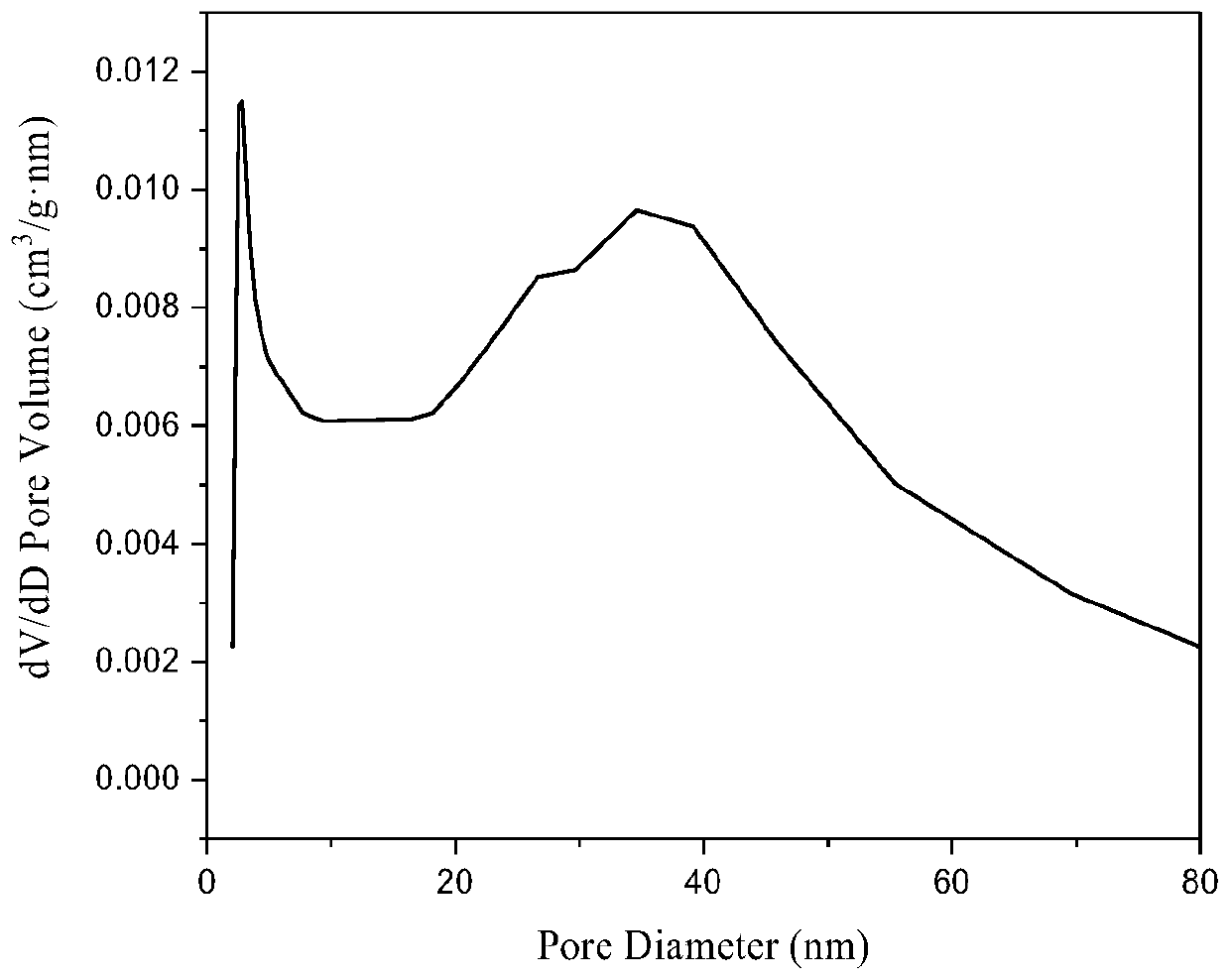

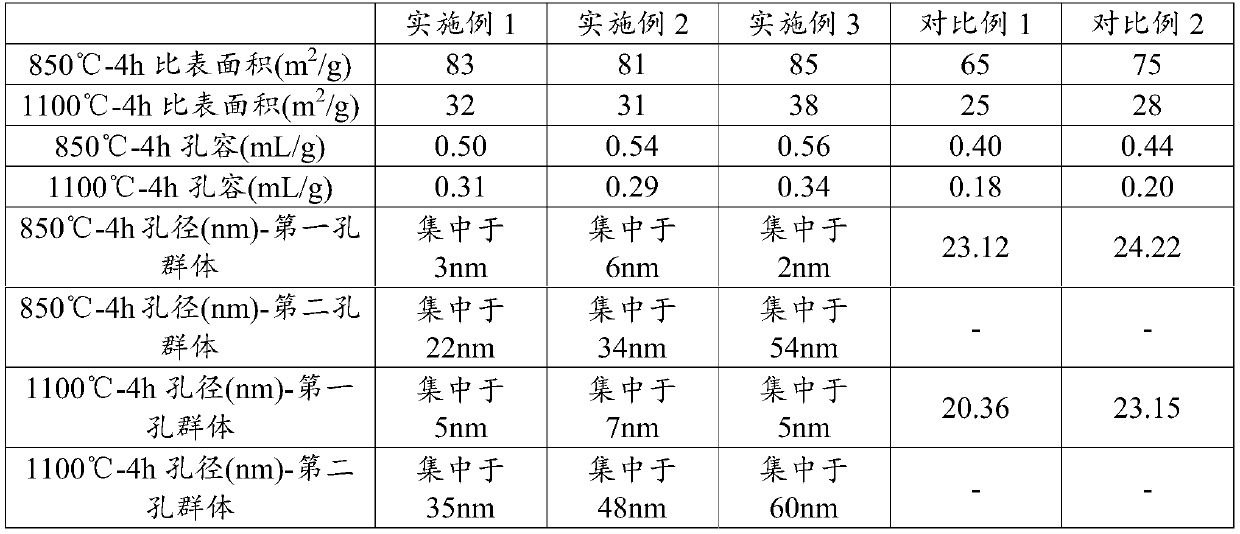

[0053] Example 1 provides a composition comprising CeO 2 40%, ZrO 2 50%, La 2 o 3 5%, Pr 6 o 11 5% cerium-zirconium composite oxide, prepared by the following method:

[0054] Take 629g zirconium oxychloride and 62g ammonium cerium nitrate and add it into 1500mL ultrapure water, and add ammonia water dropwise to the solution to adjust the pH to 6.5 to obtain the sol of the first precipitate; , 65g of lanthanum nitrate and 58g of praseodymium nitrate were dissolved and mixed with ammonia water and added dropwise to the above-mentioned first precipitate, and the pH was adjusted to 10 to obtain the second precipitate of cerium hydroxide-zirconium hydroxide-lanthanum hydroxide-praseodymium hydroxide things.

[0055] Filter and wash the above precipitate for at least 3 times, then add it to a 10L reaction kettle, heat at 210°C for 36 hours to obtain a composite oxide of ceria-zirconia-lanthanum oxide-praseodymium oxide, then add 22-300g of lauric acid, and oxidize at 850°...

Embodiment 2

[0061] Example 2 provides a composition comprising CeO 2 20%, ZrO 2 73%, La 2 o 3 2%, Nd 2 o 3 5% cerium-zirconium composite oxide, prepared by the following method:

[0062] Take 918g of zirconium oxychloride and 31g of cerium ammonium nitrate and add them to 1500mL of ultrapure water, and add ammonia water dropwise to the solution to adjust the pH value to 6.5 to obtain the sol of the first precipitate; take 280g of cerium ammonium nitrate, 102g of oxychloride Zirconium, 26g of lanthanum nitrate and 65g of neodymium nitrate are dissolved and mixed with aqueous ammonia and added dropwise to the above-mentioned first precipitate, and the pH is adjusted to 11 to obtain the second product of cerium hydroxide-zirconium hydroxide-lanthanum hydroxide-neodymium hydroxide Precipitate.

[0063] Filter and wash the above precipitate for at least 3 times, then add it to a 10L reaction kettle, heat at 210°C for 36 hours to obtain a composite oxide of ceria-zirconia-lanthanum ox...

Embodiment 3

[0066] Example 3 provides a composition comprising CeO 2 25%, ZrO 2 60%, La 2 o 3 3%, Y 2 o 3 12% cerium-zirconium composite oxide, prepared by the following method:

[0067] Take 754g of zirconium oxychloride and 39g of cerium ammonium nitrate and add them to 1500mL of ultrapure water, and add ammonia water dropwise to the solution to adjust the pH to 6.5 to obtain the sol of the first precipitate; take 350g of cerium ammonium nitrate, 84g of cerium oxychloride , 26g of lanthanum nitrate and 35g of yttrium nitrate were dissolved and mixed with ammonia water and added dropwise to the above-mentioned precipitate to adjust the pH=11 to obtain the second precipitate of cerium hydroxide-zirconium hydroxide-lanthanum hydroxide-yttrium hydroxide.

[0068] Filter and wash the above precipitate for at least 3 times, then add it to a 10L reaction kettle, heat at 210°C for 36h to obtain a composite oxide of ceria-zirconia-lanthanum oxide-yttrium oxide, then add 22-300g of lauri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Oxygen storage capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com