A refined naphthalene method for industrial naphthalene production

A technology for industrial naphthalene and refined naphthalene, applied in chemical instruments and methods, purification/separation of hydrocarbons, physical/chemical process catalysts, etc., can solve problems such as increasing processing costs, affecting the yield of refined naphthalene, and multiple hydrogen raw materials, to achieve The effect of improved desulfurization rate, good comprehensive economy and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of industrial naphthalene selective hydrogenation catalyst provided by an aspect of the embodiments of the present invention, the preparation method comprises:

[0029] 1) Preparation of carrier: mix pseudo-boehmite, short multi-walled carbon nanotubes, surfactant (such as polyethylene glycol octyl phenyl ether Triton X-100), and pore-enlarging agent (such as carbon black powder) After homogenization (the concentration of the surfactant in the obtained mixture is preferably 0.5-2.0 wt%), an extrusion aid (such as an aqueous solution of citric acid) is added, and the amount of the aqueous solution is added to meet the carrier molding, and then kneaded and extruded to obtain Strip carrier.

[0030] 2) The aqueous solutions of technetium and palladium metal component precursors are respectively sprayed and impregnated into the carrier obtained in step 1). Roasting treatment to obtain the selective hydrogenation catalyst.

[0031] In some embodiments, the industria...

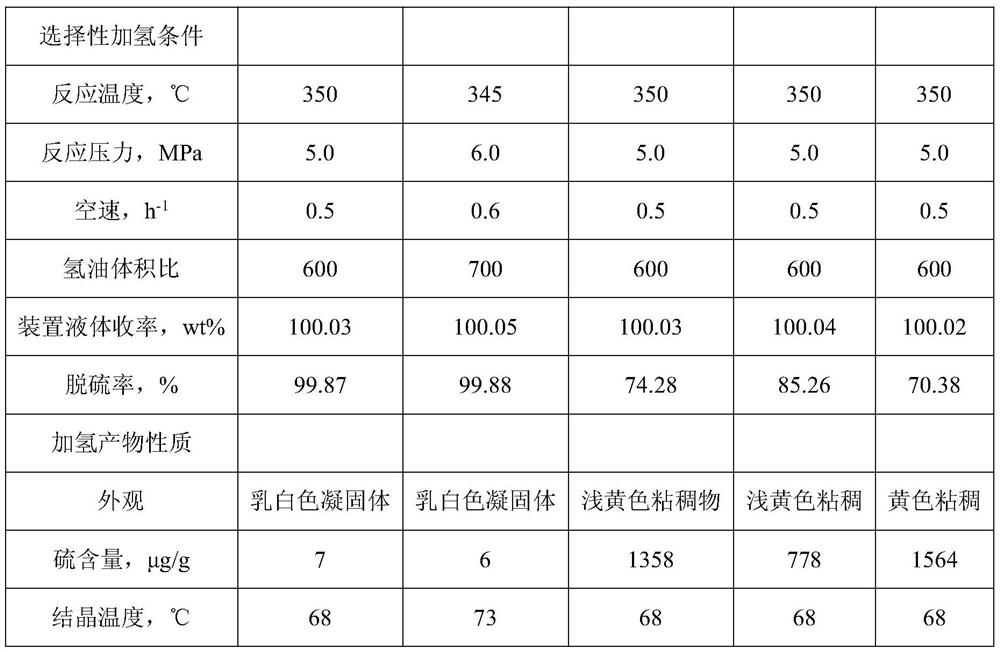

Embodiment 1

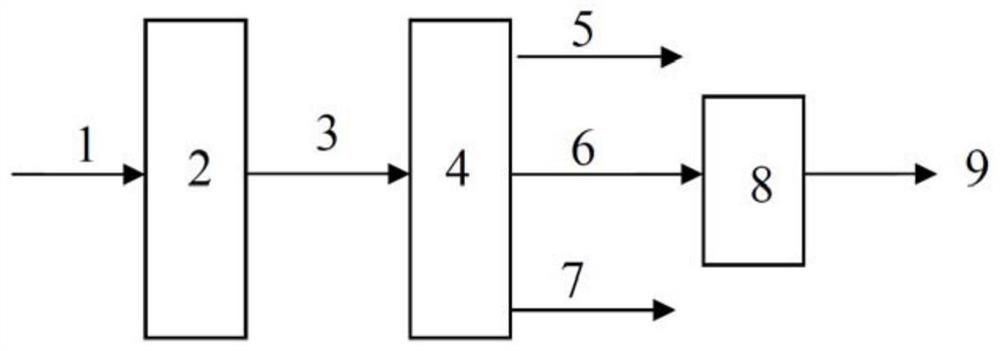

[0044] Embodiment 1: the method that industrial naphthalene produces refined naphthalene in this embodiment refers to figure 1 shown. Wherein, the catalyst used in the selective hydrotreating reaction zone is A catalyst.

Embodiment 2

[0045] Embodiment 2: the method that industrial naphthalene produces refined naphthalene in this embodiment refers to figure 1 shown. Wherein, the catalyst used in the selective hydrotreating reaction zone is B catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com