Multifunctional compound fabric and production method thereof

A composite fabric, multi-functional technology, applied in physical processing, textiles and papermaking, fiber types, etc., can solve the problem of limiting the application range of conductive polymer composite fabrics, ignoring the application of electromagnetic shielding materials, and being unable to overcome the embrittlement of polymer matrix, etc. problems, to achieve excellent electrothermal and photothermal conversion performance, excellent superhydrophobic performance, and suitable for large-scale manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

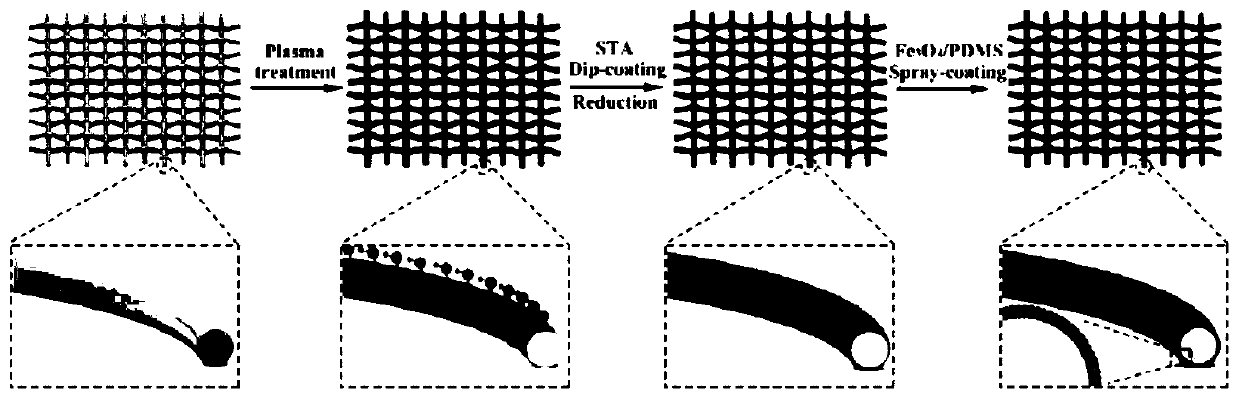

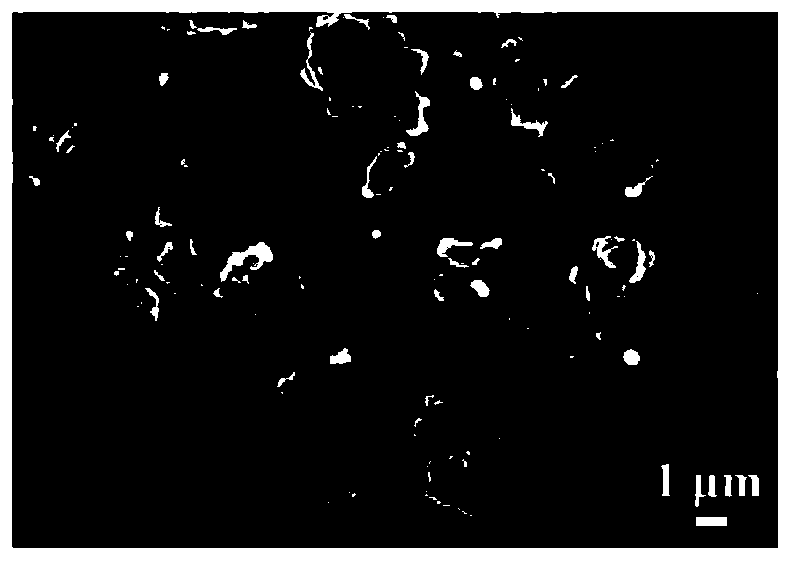

[0030] (1) O 2 Atmospheric plasma treatment was performed for 10 minutes before use. Silver trifluoroacetate was weighed and dissolved in ethanol to prepare a 25 wt.% STA solution. Soak the above-mentioned surface-modified PP non-woven fabric in 25wt.% STA solution for 40 minutes, take it out and dry it, reduce it with hydrazine hydrate for 30 minutes, rinse it repeatedly with deionized water, and dry it at 60°C to obtain a surface Silver-plated PP fabric. The preparation process is as figure 1 As shown, the microscopic morphology of the prepared multifunctional composite fabric was observed with a scanning electron microscope as Figure 2a .

[0031] (2) Test: contact angle test, use the OCA20 contact angle measuring instrument to test the contact angle of the silver-plated PP fabric, drop 5μL of distilled water on the surface of the fabric, in order to ensure the accuracy of the results, test 5 times, take the average value, and test see results image 3 ; Electromagne...

Embodiment 2

[0040] (1) O 2Atmospheric plasma treatment was performed for 10 minutes before use. Silver trifluoroacetate was weighed and dissolved in ethanol to prepare a 25 wt.% STA solution. Soak the above-mentioned surface-modified PP non-woven fabric in 25wt.% STA solution for 40 minutes, take it out and dry it, reduce it with hydrazine hydrate for 30 minutes, rinse it repeatedly with deionized water, and dry it at 60°C to obtain a surface Silver-plated PP fabric. Combining PDMS with Fe 3 o 4 Add to n-heptane, drop 0.1g oleylamine, ultrasonically disperse for 1h, Fe 3 o 4 The mass fraction is 0.8wt.%, and the PDMS mass fraction is 0.8wt.%. Set the spraying parameters: the spraying pressure is 60kPa, the spraying distance is 25cm, the two sides of the silver-plated fabric are sprayed once with the mixed dispersion liquid, and the spraying time is 5s each time. Hydrophobic multifunctional fabric, the preparation process such as figure 1 As shown, the microscopic morphology of the...

Embodiment 3

[0043] (1) O 2 Atmospheric plasma treatment was performed for 10 minutes before use. Silver trifluoroacetate was weighed and dissolved in ethanol to prepare a 25 wt.% STA solution. Soak the above-mentioned surface-modified PP non-woven fabric in 25wt.% STA solution for 40 minutes, take it out and dry it, reduce it with hydrazine hydrate for 30 minutes, rinse it repeatedly with deionized water, and dry it at 60°C to obtain a surface Silver-plated PP fabric. Combining PDMS with Fe 3 o 4 Add to n-heptane, drop 0.1g oleylamine, ultrasonically disperse for 1h, Fe 3 o 4 The mass fraction is 0.8wt.%, and the PDMS mass fraction is 0.8wt.%. Set the spraying parameters: the spraying pressure is 60kPa, the spraying distance is 25cm, and the mixed dispersion liquid is sprayed on both sides of the silver-plated fabric for 3 times, each spraying time is 5s, and the curing time is 20 minutes after each spraying, and 80°C after 3 times The superhydrophobic multifunctional fabric with e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com