Cobalt-based petal-like composite material loaded by silver nanoparticles and preparation method and application of composite material

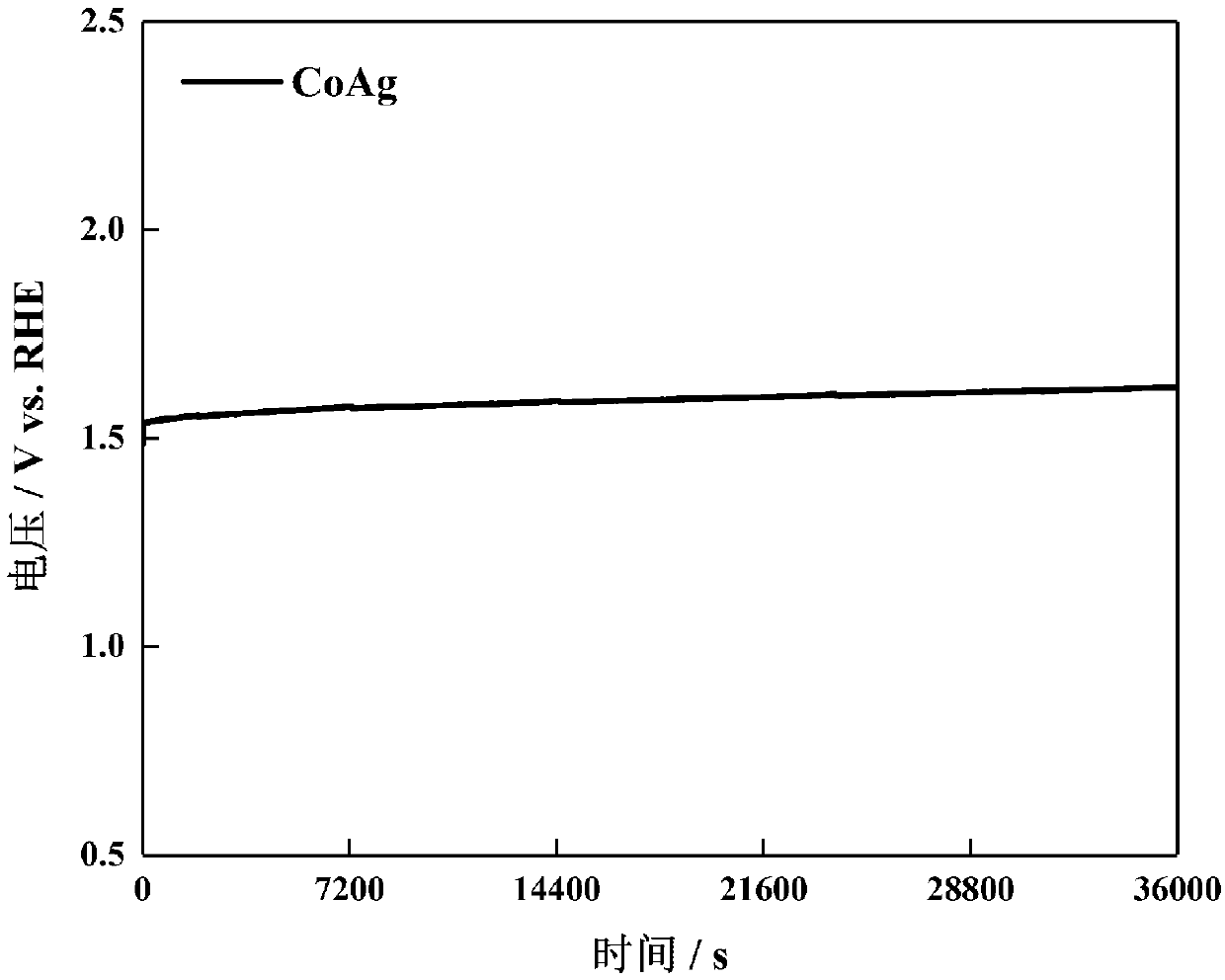

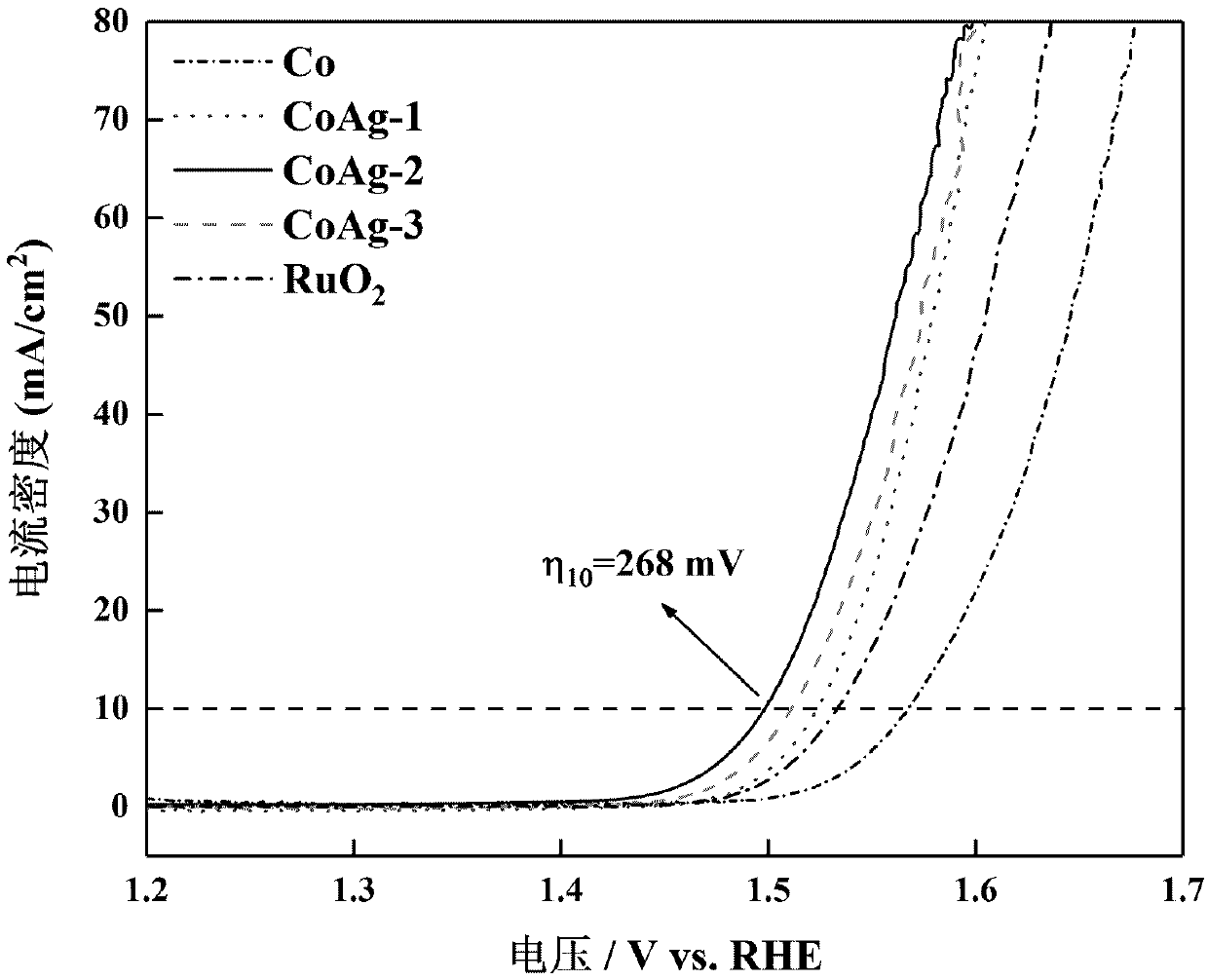

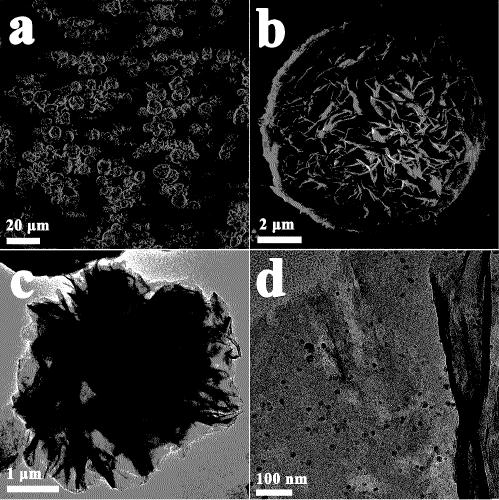

A technology of silver nanoparticles and composite materials, applied in the field of electrocatalysis, can solve the problems of limiting commercial applications, increasing catalyst costs, poor catalytic activity, etc., and achieves excellent OER performance, good long-term stability, and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take 0.50g of cobalt acetate and dissolve it in 50.0ml of anhydrous methanol solution, stir magnetically to make it completely dissolved, add 0.18g of 2-methylimidazole, and disperse by ultrasonic for 20-30 minutes.

[0027] (2) Transfer the above-mentioned solution to a 100ml reaction kettle, set the reaction temperature to 120°C, and set the reaction time to 12 hours. After cooling to room temperature naturally, filter and wash with anhydrous methanol and secondary water three times respectively. Dry it in a vacuum oven at 60°C and grind it for later use. The sample obtained at this time is designated as Co.

[0028] (3) Take 50.0 mg of the powder sample obtained above and dissolve it in 20.0 ml of anhydrous methanol, ultrasonically disperse it fully, then add 1.0 ml of 10.0 mmol / L silver nitrate solution, stir magnetically for 1 hour, then add 5.0 ml drop by drop Prepare 0.25 mol / L sodium borohydride solution with ice water, transfer the experimental device to a ...

Embodiment 2

[0030] (1) Take 0.50g of cobalt acetate and dissolve it in 50.0ml of anhydrous methanol solution, stir magnetically to make it completely dissolved, add 0.18g of 2-methylimidazole, and disperse by ultrasonic for 20-30 minutes.

[0031] (2) Transfer the above-mentioned solution to a 100ml reaction kettle, set the reaction temperature to 120°C, and set the reaction time to 12 hours. After cooling to room temperature naturally, filter and wash with anhydrous methanol and secondary water three times respectively. Dry it in a vacuum oven at 60°C and grind it for later use. The sample obtained at this time is designated as Co.

[0032] (3) Take 50.0 mg of the powder sample obtained above and dissolve it in 20.0 ml of anhydrous methanol, ultrasonically disperse it fully, then add 2.0 ml of 10.0 mmol / L silver nitrate solution, stir magnetically for 1 hour, then add 5.0 ml drop by drop Prepare 0.25 mol / L sodium borohydride solution with ice water, transfer the experimental device to a ...

Embodiment 3

[0034] (1) Take 0.50g of cobalt acetate and dissolve it in 50.0ml of anhydrous methanol solution, stir magnetically to make it completely dissolved, add 0.18g of 2-methylimidazole, and disperse by ultrasonic for 20-30 minutes.

[0035] (2) Transfer the above-mentioned solution to a 100ml reaction kettle, set the reaction temperature to 120°C, and set the reaction time to 12 hours. After cooling to room temperature naturally, filter and wash with anhydrous methanol and secondary water three times respectively. Dry it in a vacuum oven at 60°C and grind it for later use. The sample obtained at this time is designated as Co.

[0036] (3) Dissolve 50.0 mg of the powder sample obtained above in 20.0 ml of anhydrous methanol, disperse it fully by ultrasonication, then add 4.0 ml of 10.0 mmol / L silver nitrate solution, stir magnetically for 1.0 hour, then add 5.0 ml drop by drop Prepare 0.25 mol / L sodium borohydride solution with ice water, transfer the experimental device to a dark p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com