Nuclear-shell nanogold composite material and preparation method and application

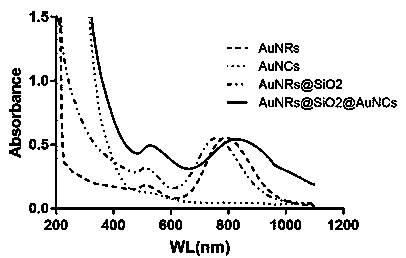

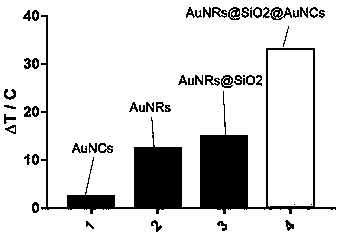

A composite material and nano-gold technology, which is applied in the field of core-shell nano-gold composite materials and preparation, can solve problems such as poor stability and poor biocompatibility, and achieve the effects of large loading capacity, simple preparation method, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

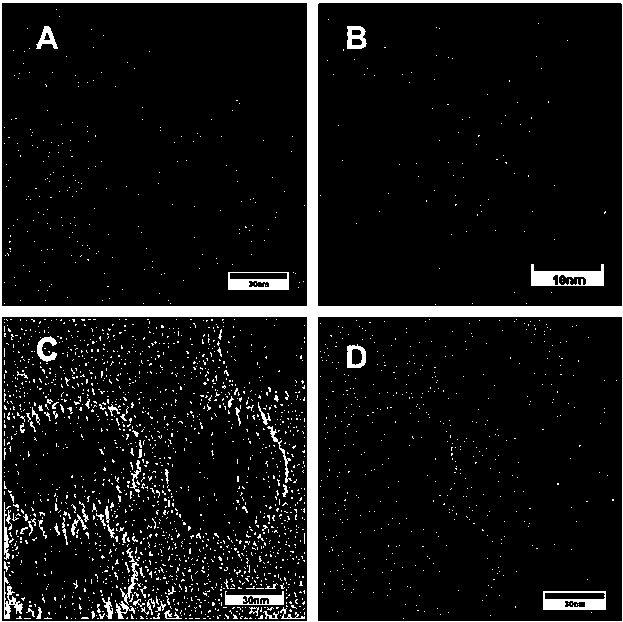

Method used

Image

Examples

preparation example Construction

[0046] A preparation method of a core-shell type nano-gold composite material, comprising the steps of:

[0047] 1) Preparation of gold nanorod solution (AuNRs) by seed-free method:

[0048]Dissolve CTAB in ultrapure water, add chloroauric acid solution, silver nitrate solution, ascorbic acid solution, and sodium borohydride solution in sequence, then stir for 10-30s in a water bath at 30-40 degrees, and let it stand for 4-8 hours. Centrifuge at a speed of more than 10,000 rpm, remove the supernatant to obtain the lower colloidal solution, wash with deionized water, remove excess CTAB solution, and remove the lower colloidal solution to obtain the gold nanorod solution;

[0049] The molar ratio of each reaction component is CTAB: chloroauric acid: silver nitrate: ascorbic acid: sodium borohydride=80000:40-50:100-150:500-600:1-2.

[0050] Preferably, the molar ratio of each reaction component is CTAB: chloroauric acid: silver nitrate: ascorbic acid: sodium borohydride = 80000:...

Embodiment 1

[0076] 1) Preparation of gold nanorod solution (AuNRs) by seed-free method:

[0077] Synthesize gold nanorods by seedless method, first weigh 1.8218g CTAB powder and dissolve it in 50ml ultrapure water, and dissolve it by ultrasonic;

[0078] Take the dissolved CTAB 10ml 0.1M and put it into the Erlenmeyer flask, add 208ul 0.024M chloroauric acid solution, 100ul 0.01M silver nitrate solution, 60ul 0.1M ascorbic acid solution successively under stirring in a 37 degree water bath. Then add 16ul 1mM sodium borohydride solution and stir for 25s. After the solution was allowed to stand for 6 hours, it was centrifuged with ultrapure water to remove excess CTAB to obtain a gold nanorod solution.

[0079] The sodium borohydride solution is prepared from ice water.

[0080] 2) Preparation of gold nanorods wrapped in mesoporous silica,

[0081] After sonicating the prepared gold nanorods for 15 minutes, take 10ml and add it to the Erlenmeyer flask, stir in a 30-degree water bath and ...

Embodiment 2

[0101] 1) Preparation of gold nanorod solution

[0102] Utilize the seedless method to synthesize gold nanorods, first weigh 1.8218g CTAB powder and dissolve it in 50ml ultrapure water, and dissolve it by ultrasonic; take the dissolved CTAB 10ml 0.1M and add it to the Erlenmeyer flask, and add 208 μl of it successively under stirring in a 37-degree water bath. .024M chloroauric acid solution, 100ul 0.01M silver nitrate solution, 60ul 0.1M ascorbic acid solution. Then add 16ul 1mM sodium borohydride solution (prepared with ice water), and stir for 25s. After the solution was allowed to stand for 6 hours, it was centrifuged with ultrapure water to remove excess CTAB to obtain a gold nanorod solution.

[0103] 2) Preparation of gold nanorods wrapped in mesoporous silica, after ultrasonication of the prepared gold nanorods for 15 minutes, take 10ml into the conical flask, stir in a 30-degree water bath, add 100ul 0.1M NaOH to react for 30min, and then add in three times 40ul TEO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com