Enzyme/calcium salt/GO (graphene oxide) functional nanocomposite and preparation method thereof

A nano-composite material and composite material technology, applied in the field of enzyme/calcium salt/graphene oxide functional nano-composite material and its preparation, to achieve the effect of simple equipment and gentle and simple experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An enzyme / calcium salt / graphene oxide functional nanocomposite material, comprising the following components in mass percentage: 27.17% tyrosinase, 67.39% calcium phosphate crystal, and 5.43% GO.

[0036] (1) Preparation of materials

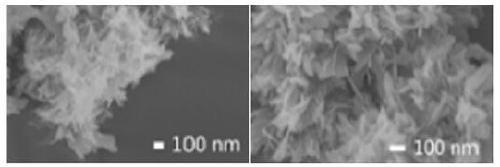

[0037] 4 mg GO was ultrasonically dissolved in PBS (0.06 mol / L) with a pH of 8.0, 20 mg tyrosinase and 0.667 mL 240 mM calcium chloride solution were added in sequence, shaken well, and reacted at room temperature for 48 h. Then the precipitate was separated, washed and freeze-dried in a vacuum freeze dryer for 4 h, and then the dried nanocomposite was observed with a scanning electron microscope, and its nanostructure was as follows: figure 1 . Depend on figure 1 It can be seen that the composite nanostructure is a uniform nanoflower cluster composed of 80-120 nm rod-like structures.

[0038] (2) Determination method and results of laccase activity in nanocomposite materials

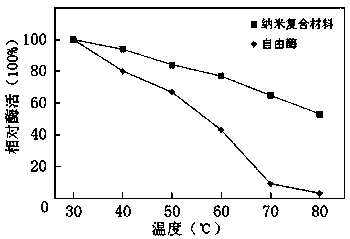

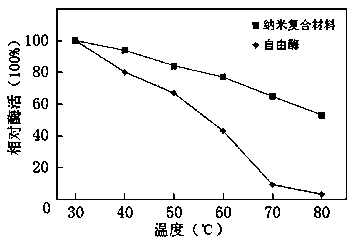

[0039] Take 3.5 mL of citric acid-disodium hydrogen phosp...

Embodiment 2

[0043] An enzyme / calcium salt / graphene oxide functional nanocomposite material, comprising the following components in mass percentage: laccase 40%, calcium phosphate crystal 32%, GO 28%.

[0044] (1) Preparation method of nanocomposite materials

[0045] 2 mg GO was ultrasonically dissolved in PBS (0.2 mol / L) with a pH of 5.7, 15 mg laccase and 0.667 mL of 120 mM calcium chloride solution were added in turn to shake well, and the reaction was carried out at 25 °C and 140 rpm in a shaker for 48 h. Afterwards, the precipitate was separated, washed and freeze-dried in a vacuum freeze dryer at -30 °C for 6 h.

[0046] (2) Determination method and results of laccase activity in nanocomposite materials

[0047] Take 3.5 mL of citric acid-disodium hydrogen phosphate buffer solution with a pH of 4.6, add 0.5 mL of 2 mM ABTS solution, and then add 1 mL of the sample solution to be tested to start the reaction. After a certain period of time, filter the reaction solution with a filter h...

Embodiment 3

[0053] An enzyme / calcium salt / graphene oxide functional nanocomposite material, comprising the following components in mass percentage: 40% carbonic anhydrase, 32% calcium phosphate crystals, and 28% GO.

[0054] (1) Preparation method of nanocomposite materials

[0055] Dissolve 5 mg GO ultrasonically in PBS (0.2 mol / L) with a pH of 8.5, add 15 mg carbonic anhydrase and 0.667 mL 120 mM calcium acetate solution in turn, shake well, and react in a shaker at 25 °C and 140 rpm for 48 h , and then the precipitate was separated, washed and freeze-dried in a vacuum freeze-dryer at -30 °C for 6 h.

[0056] (2) Determination method and results of carbonic anhydrase activity in nanocomposite materials

[0057] Mix 0.3 mL of the enzyme solution to be tested, 2.4 mL of PBS (pH=7), and 0.3 mL of p-NPA (0.02 M in acetonitrile), and react for a certain period of time to measure the difference in absorbance , to calculate the enzyme activity. Finally, the enzyme activity of carbonic anhyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com