A basic flux-cored welding wire for high-strength weather-resistant and refractory steel welding

A flux-cored welding wire and weather-resistant technology, which is applied in welding equipment, welding medium, welding equipment, etc., can solve the problems that have not been promoted and the poor process performance of alkaline materials, and achieve arc stability, beautiful shape, and good slag fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of basic flux-cored welding wire of the present invention is as follows:

[0037] Steel strip: Thickness (mm)×width (mm) of steel strip: 0.6-0.9×10 and related strips, weight ratio between 15-30%; welding wire diameter: Φ1.2mm-Φ1.6mm.

[0038] The production of flux-cored welding wire is a mature technology in the industry. Its principle is: purchase low-carbon steel strips for flux-cored welding wires, use special equipment to roll the thin steel strips into semicircular shapes such as U-shaped, etc., add alloy powder to form welding cores, and roll Sealing is made to form a very long and thin metal tube covered with a welding core, and then rolled or cold drawn to form a finished flux-cored wire with a diameter of Φ1.2mm-Φ1.6mm.

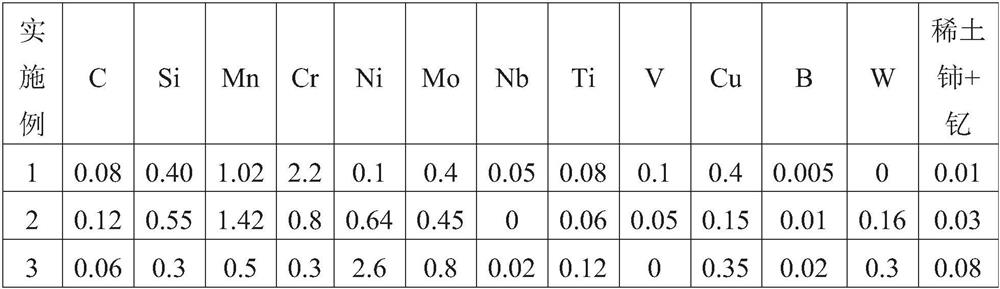

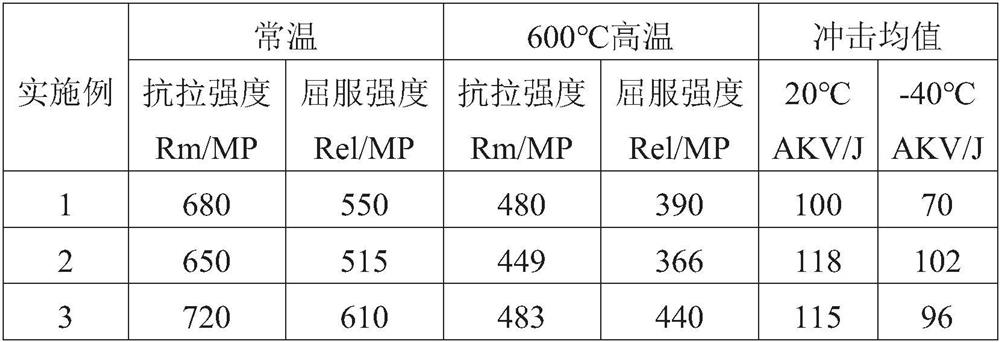

Embodiment 1

[0040] The composition of the flux-cored wire powder in this embodiment is: magnesia: 18g; fluorite: 19g; barium fluoride: 4g; zircon sand: 12g; manganese ore: 2g; rutile: 10g; marble: 3.5g; 2.5g; lithium fluoride 1g; high-carbon ferrochrome 4g; micro-carbon ferrochrome 10.5g; nickel powder 0.4g; ferrosilicon: 2.2g; manganese powder 4.2g; : 1.6g; ferroboron: 0.1g; ferroniobium: 0.4g; ferrovanadium: 0.8g; cerium oxide: 0.1g and yttrium oxide 0.3g.

[0041] Common carbon steel strip H08A is used, with a thickness of 0.8mm and a width of 10mm. The steel strip was rolled into a U shape, and the powders in the above examples were added to the steel strip to form welding cores respectively, with a filling rate of 25%. Rolling and sealing to form a very long and thin metal tube covered with a welding core, and then rolling or cold drawing to form a finished flux-cored wire with a diameter of Φ1.6mm.

Embodiment 2

[0043] The composition of the flux-cored wire powder in this embodiment is: magnesia: 33.4g; fluorite: 5g; barium fluoride: 8g; zircon sand: 6.7g; manganese ore: 6g; rutile: 8.5g; marble: 2g; Alloy: 1g; lithium carbonate 1g; high-carbon ferrochrome 2g; micro-carbon ferrochrome 4.5g; graphite 1g; nickel powder 3.2g; ferrosilicon: 3.6g; manganese powder 7.2g; copper powder: 0.8g; molybdenum powder 2.2g Ferro-titanium: 1.2g; Ferro-boron: 0.3g; Tungsten powder: 0.8g; Ferrovanadium: 0.4g; cerium oxide 1g and yttrium oxide 0.2g.

[0044] Common carbon steel strip H08A is used, with a thickness of 0.8mm and a width of 10mm. The steel strip was rolled into a U shape, and the powders in the above embodiments were added to the steel strip to form welding cores respectively, with a filling rate of 20%. Rolling and sealing to form a very long and thin metal tube covered with a welding core, and then rolling or cold drawing to form a finished flux-cored wire with a diameter of Φ1.6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com