Core-shell type tertiary carbon redispersible latex powder and preparation method thereof

A technology of redispersing latex powder and core-shell type, which is applied in the direction of powder coatings, coatings, paints containing biocide, etc., and can solve the problem that dry powder coatings are not resistant to high enough scrubbing times, the product is difficult to achieve high quality, and the use of latex powder is limited To achieve the effect of strong water resistance, film formation without softening, film formation and stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

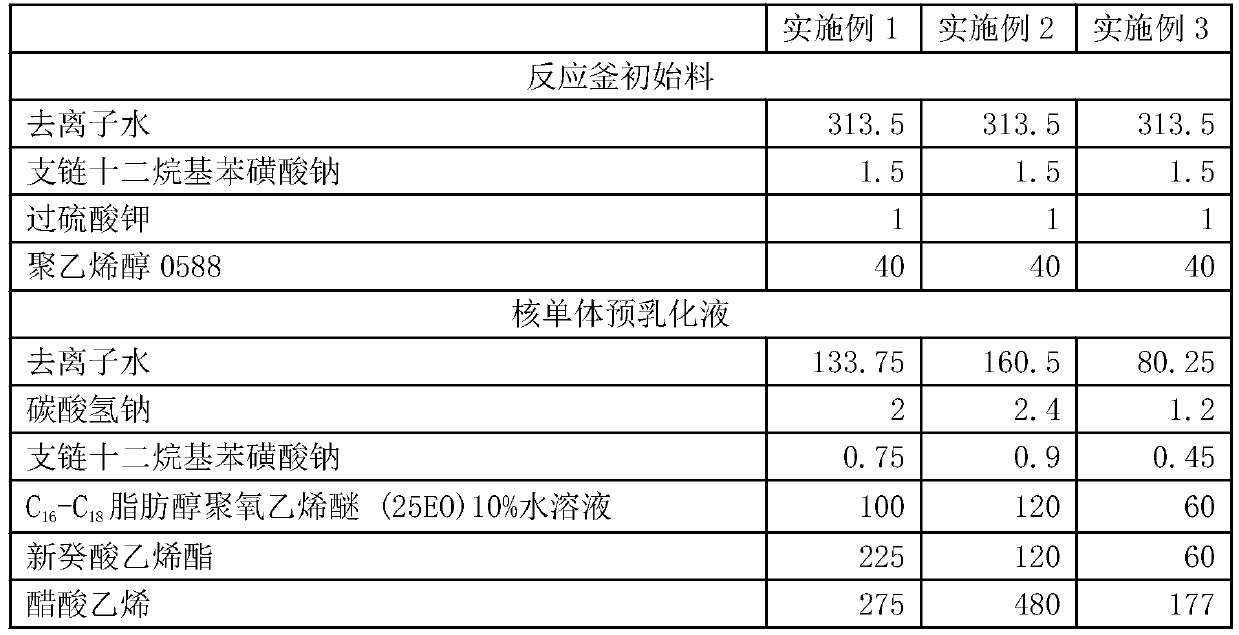

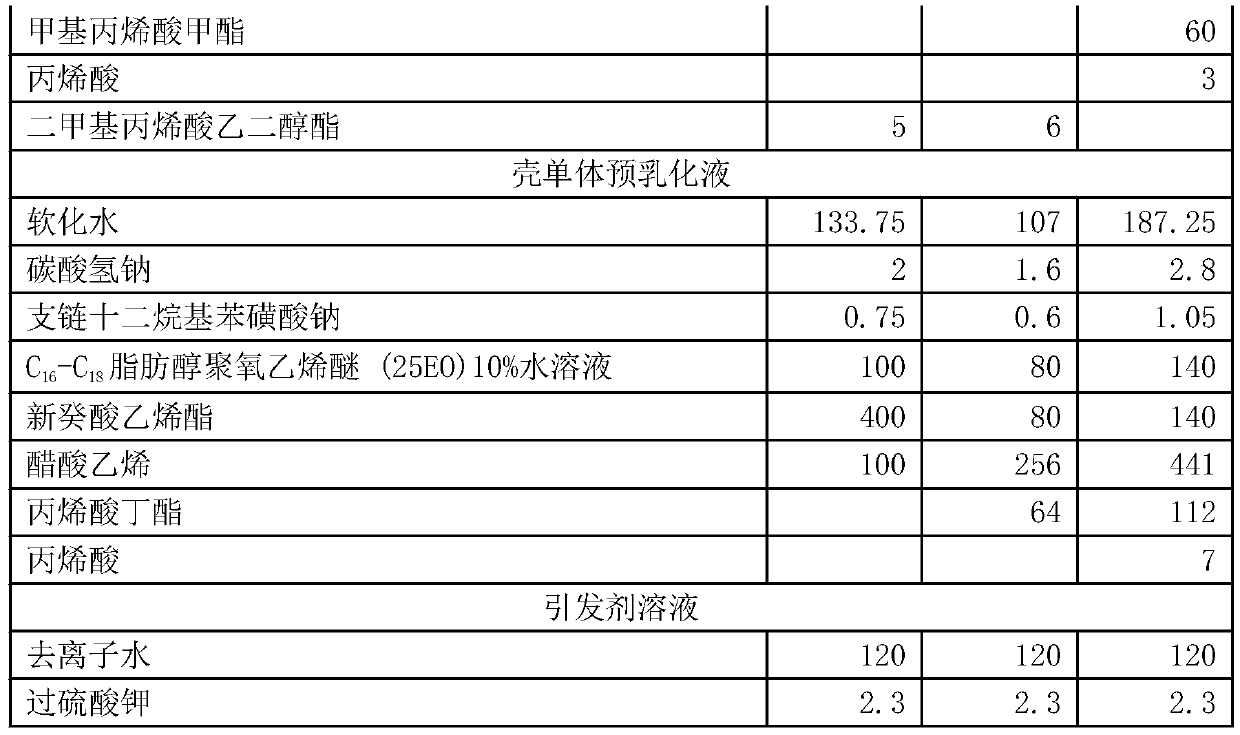

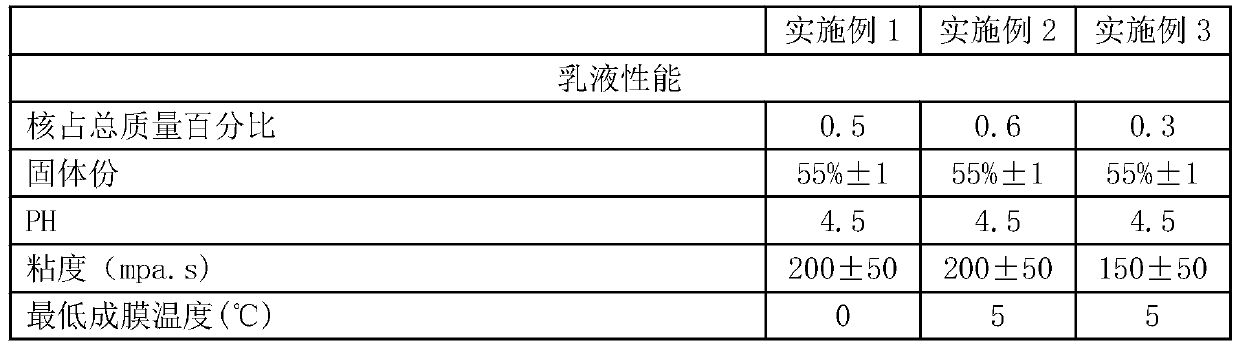

[0068] Embodiment 1-3, the preparation of core-shell type tertiary carbon emulsion :

[0069] Formulation table (unit is mass part):

[0070]

[0071]

[0072] Preparation:

[0073] The emulsion polymerization reactor is a reaction flask equipped with a reflux condenser, a stirrer, a thermometer, and a monomer and initiator feeding tube. Use a peristaltic pump to inject the monomer pre-emulsion and initiator into the reactor. The reactor was heated with a water bath.

[0074] Prepare stable core and shell monomer pre-emulsions by adding monomers to a vigorously stirred aqueous solution according to the formula table. The reactor initial material was heated to 60° C. under nitrogen flow, and when it reached 60° C., the nitrogen flow was stopped, and 10% of the total mass of the core layer monomer pre-emulsion was added into the reactor. When the material in the container has been polymerized, the reflux of vinyl acetate stops, the temperature reaches 76°C, and then m...

Embodiment 4-6

[0079] Example 4-6, preparation of core-shell copolymerized tertiary carbon redispersible latex powder:

[0080] Formulation table (unit is mass part):

[0081]

[0082] Embodiment 4-6 preparation method:

[0083] The equipment is a centrifugal spray dryer, and the preparation steps are as follows:

[0084] (1) Make 0588 polyvinyl alcohol protective colloid into 20% aqueous solution.

[0085] (2) Add the tertiary carbon polymer emulsion and protective colloid aqueous solution into the container, start stirring at 1000r / min for 10 minutes, add water and stir for 5 minutes, and configure it as a pre-spraying feed solution with a solid content of 40%.

[0086] (3) Turn on the heating and induced draft fan of the centrifugal spray dryer, and heat the incoming air to 130°C.

[0087](4) Turn on the centrifugal atomizer (turntable diameter 50mm), make the centrifugal speed reach 25000rpm, turn on the feeding pump, slowly increase the feeding speed, control the outlet temper...

Embodiment 7-9

[0093] Embodiment 7-9, the preparation of tertiary carbon dry powder coating:

[0094] The tertiary carbon redispersible latex powder in the above examples of the present invention is applied to the preparation of dry powder coatings.

[0095] Buy a commercially available VAE redispersible latex powder as a contrast example, and its product index is as follows:

[0096] Exterior white powder, free flowing Solid content ≥98.0% Ash (1000℃) 10±2% Bulk density (g / l) 400~600 Average particle size (μm) ~80 50% aqueous solution viscosity (Pas) 1.0~3.0 PH value 6~8 Minimum film forming temperature (°C) 0℃

[0097] Formula table of dry powder coating (unit is mass part):

[0098]

[0099] Preparation:

[0100] (1) Add the pigments and fillers to a double-helix mixer and stir for 5 minutes, then add tertiary carbon redispersible latex powder, cellulose and other additives, and mix for 40 minutes, and then use a 120-mesh vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com