Shielding coating applied to electric power facilities and preparation method thereof

A technology for shielding coatings and power facilities, used in conductive coatings, epoxy resin coatings, coatings, etc., can solve problems such as general electromagnetic wave anti-interference performance, and achieve the effect of improving the quality of the coating, making up for the difficulty of dispersion and good conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

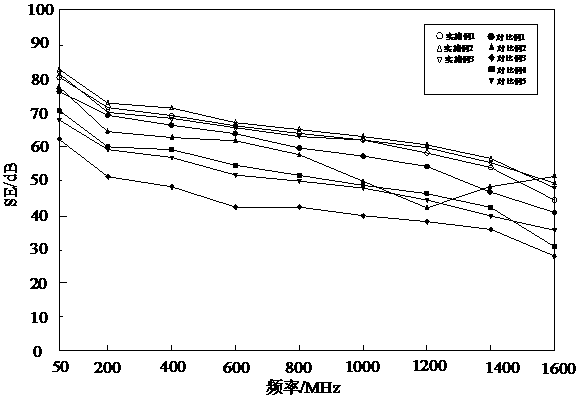

Image

Examples

preparation example Construction

[0033] Nickel plating of the present invention is to adopt the preparation method of electroless plating, obtains nickel-plated mica powder, and concrete preparation method comprises the following steps:

[0034] S1: prepare electroless nickel plating liquid, the weight percentage of this chemical nickel plating liquid is composed of: nickel sulfate 200-230g / L, nickel sulfamate 50~55g / L, potassium hypophosphite 15-18g / L, potassium sodium tartrate 8 -10g / L, sodium ethylhexyl sulfate 0.5-0.7g / L;

[0035] S2: The sensitized mica powder is plated with an electroless nickel plating solution for 12-15 minutes, the nickel plating temperature is 60-65° C., and the pH value is 4.1-4.3 to obtain nickel-plated mica powder.

[0036] Experiments have shown that when the nickel plating rate on the surface of mica is greater than 70%, and the mass percentage of nickel plating is 23.5-28.3%, its conductivity is close to that of nickel powder. Among them, nickel plating rate=area of nickel-...

Embodiment 1

[0046] A shielding coating applied to power facilities, made of the following raw materials in parts by weight: 15 parts of bisphenol A epoxy acrylic resin, 10 parts of styrene-methyl methacrylate resin, 30 parts of nickel-plated mica powder, 1 part of joint agent, 0.5 parts of filler and 40 parts of solvent.

[0047] The particle size of the nickel-plated mica powder is 0.05 micron.

[0048] The nickel-plated mica powder is obtained by electroless nickel plating on the surface of the treated mica powder, and the processing method of the mica powder includes a pretreatment process, and the pretreatment process is: first, take 1.8g of sodium carbonate, add Water ethanol 10ml, distilled water to make up 1L, add 50g of mica powder, stir for 20min, rinse with distilled water until neutral; then, take 10g of ammonium fluoride, add 25ml of hydrochloric acid, make up 1L with distilled water, add the mica powder, stir for 10min, rinse with distilled water into neutral.

[0049] The ...

Embodiment 2

[0057] A shielding coating applied to power facilities, made of the following raw materials in parts by weight: 18 parts of bisphenol A epoxy acrylic resin, 12 parts of styrene-methyl methacrylate resin, 32 parts of nickel-plated mica powder, 1.5 parts of joint agent, 0.8 parts of filler and 45 parts of solvent.

[0058] The particle size of the nickel-plated mica powder is 0.10 micron.

[0059] The nickel-plated mica powder is obtained by electroless nickel plating on the surface of the treated mica powder, and the processing method of the mica powder includes a pretreatment process, and the pretreatment process is: first, take 1.9g of sodium carbonate, add Water ethanol 10ml, distilled water to make up 1L, add 50g of mica powder, stir for 20min, rinse with distilled water until neutral; then, take 11g of ammonium fluoride, add 26ml of hydrochloric acid, make up 1L with distilled water, add the mica powder, stir for 10min, rinse with distilled water into neutral.

[0060] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com