Core-shell type polyurethane-acrylate emulsion, and preparation method and application thereof

A technology of acrylic emulsion and polyurethane, applied in the direction of coating, etc., can solve the problems of high viscosity, poor fluidity and film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

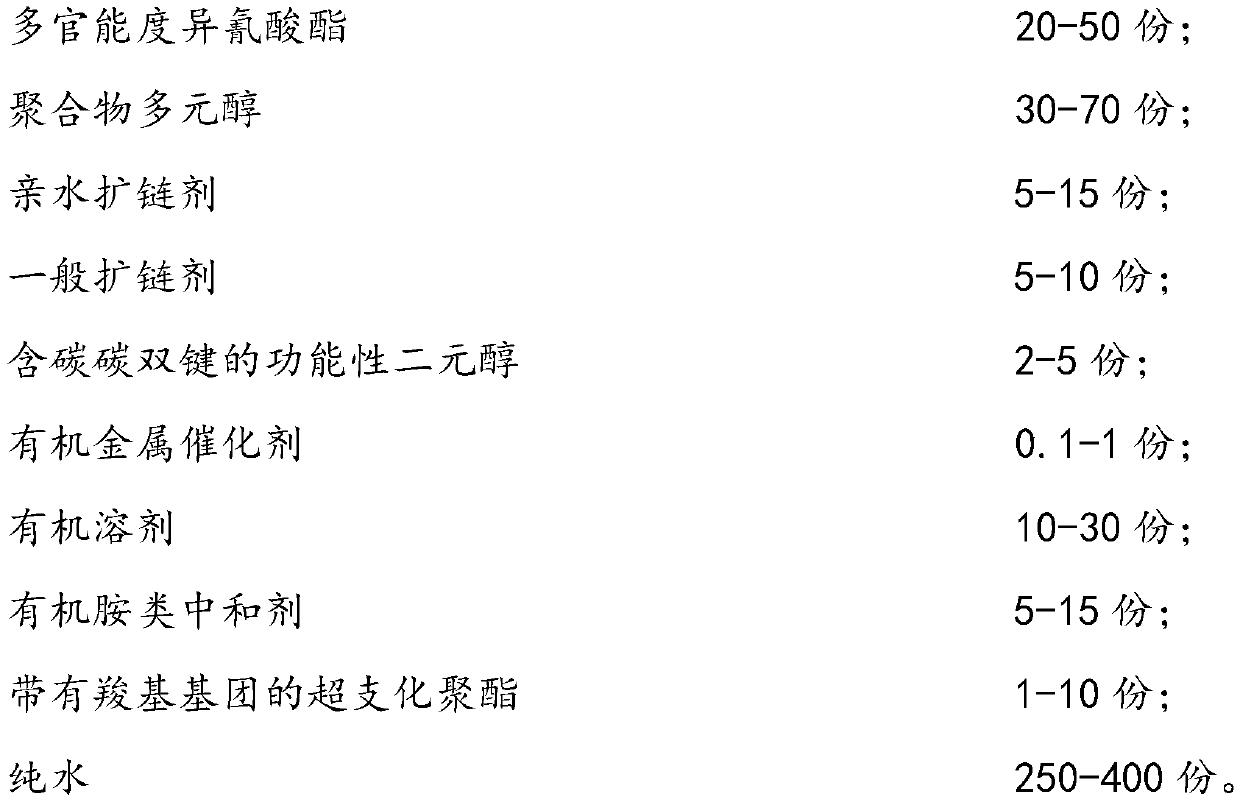

Method used

Image

Examples

preparation example Construction

[0060] The embodiment of the present invention also discloses a method for preparing the core-shell type polyurethane-acrylic emulsion as above, including the steps: S10), preparing a hyperbranched polyester modified polyurethane aqueous dispersion, and the operation steps include: first preparing isocyanate-blocked terminal polyurethane prepolymer, and then neutralize the carboxyl group in the isocyanate-terminated polyurethane prepolymer to form a salt, and then add the neutralized isocyanate-terminated polyurethane prepolymer into the hyperbranched polyester solution with carboxyl groups Carry out dispersion chain extension reaction in pure water to obtain hyperbranched polyester modified polyurethane aqueous dispersion; S20), prepare acrylate pre-emulsified monomer mixture, and its operation steps include: containing carbon-carbon double bond and can carry out copolymerization reaction monomer, acrylate and / or derivatives of methacrylate monomer, emulsifier and pure water a...

Embodiment 1

[0065] Embodiment 1: preparation has the hyperbranched polyester HPPE (I) of carboxyl group

[0066] Add 354.8g of Boltorn H40 and 74g of hexahydrophthalic anhydride into a 1L reaction kettle equipped with a stirrer, a thermometer, a nitrogen conduit and a reflux condenser, and then raise the temperature of the reaction system to 130°C. When the reaction temperature is constant, continue to keep warm at this temperature for 4-5h, and take samples every 1h to measure the acid value. When the measured value of the acid value (63mgKOH / g) reaches the theoretical value (62.8mgKOH / g), cool down the reaction system to 100° C.; finally add 48 g of triethylamine and 595 g of pure water to obtain a hyperbranched polyester with a carboxyl group having a solid content of 40%.

Embodiment 2

[0067] Embodiment 2: preparation has the hyperbranched polyester HPPE (II) of carboxyl group

[0068] Add 354.8g of Boltorn H40 and 98.6g of hexahydrophthalic anhydride into a 1L reaction kettle equipped with a stirrer, a thermometer, a nitrogen conduit and a reflux condenser, and then raise the temperature of the reaction system to 130°C. When the reaction temperature is constant, continue to keep warm at this temperature for 4-5h, during which the acid value is measured by sampling every 1h, and when the measured value of the acid value (79mgKOH / g) reaches the theoretical value (79.2mgKOH / g), the temperature of the reaction system is lowered to 100° C.; finally add 52 g of triethylamine and 400 g of pure water to obtain a hyperbranched polyester with a carboxyl group having a solid content of 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com