Ultrafiltration membrane and preparation method thereof

A technology of ultrafiltration membranes and membrane filaments, which is applied in the field of filtration membranes, can solve problems such as contamination, decrease in flux and separation performance of ultrafiltration membranes, and increase in use costs, so as to promote dissolution, improve purity and production efficiency, The effect of easy supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Polyvinylidene fluoride resin:

[0037] Polyvinylidene fluoride (PVDF) is a semi-crystalline polymer under normal conditions, with a crystallinity of about 50%. So far, 5 crystal forms, α, β, γ, 6 and ε, have been reported, which are formed under different conditions and can be transformed into each other under certain conditions (effects of heat, electric field, mechanical and radiation energy). Among the five crystal forms, the β crystal form is the most important, and PVDF used as piezoelectric and pyroelectric applications mainly contains the β crystal form. 1. PVDF has excellent chemical corrosion resistance, excellent high temperature color change resistance and oxidation resistance. 2. PVDF has excellent wear resistance, flexibility, high tensile strength and impact resistance.

[0038] The application of PVDF is mainly concentrated in the three major fields of petrochemical, electrical and electronic and fluorocarbon coatings. Due to the good chemical resistan...

Embodiment 2

[0075] In actual production, when it is the following components:

[0076] Polyvinylidene fluoride resin (28%), glycerin (3%), ethylene glycol (1%), propylene glycol (1%), nitrogen methyl pyrrolidone (50%), acetone (27%), titanium dioxide (0.2%) :

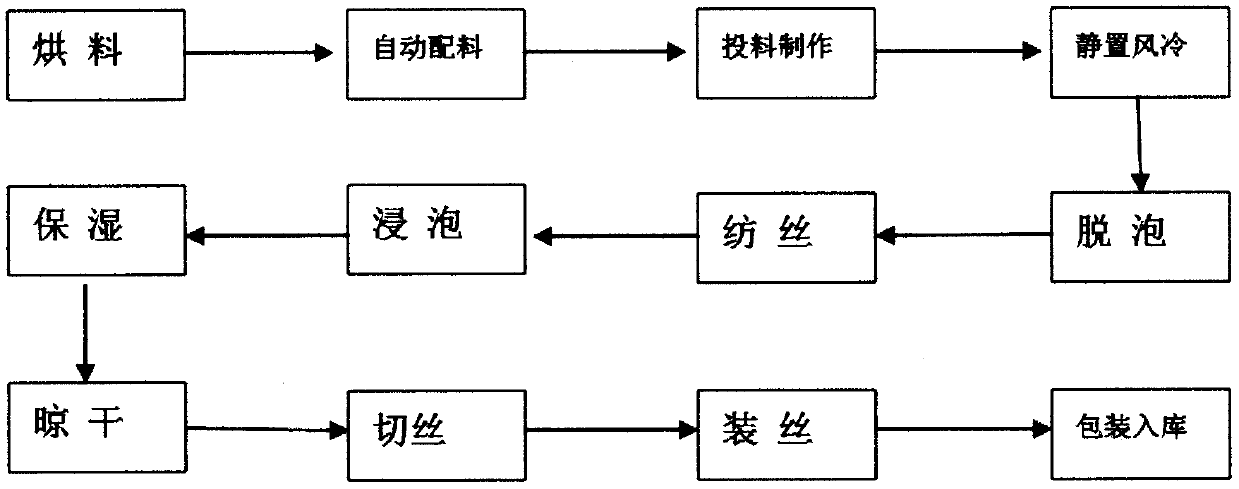

[0077]1) Drying material--high molecular polymer raw materials are easy to absorb moisture, and the raw materials need to be dried before batching, otherwise the moisture content will affect the batching ratio when feeding, thus affecting product quality. In order to ensure product quality, the drying process is carried out according to the drying time and temperature of different raw materials, and the equipment used is an oven. High molecular polymer raw materials are easy to absorb water, and the raw materials need to be dried before batching. Drying is carried out in the oven according to the drying time and temperature of different raw materials, and the polyvinylidene fluoride resin particle crystals are put into the drying ...

Embodiment 3

[0096] Polyvinylidene fluoride resin (28%), glycerin (3%), ethylene glycol (1%), polyvinyl alcohol (1%), nitrogen methyl pyrrolidone (50%), acetone (27%), trioxide Aluminum (0.2%):

[0097] 1) Drying material--high molecular polymer raw materials are easy to absorb moisture, and the raw materials need to be dried before batching, otherwise the moisture content will affect the batching ratio when feeding, thus affecting product quality. In order to ensure product quality, the drying process is carried out according to the drying time and temperature of different raw materials, and the equipment used is an oven. High molecular polymer raw materials are easy to absorb water, and the raw materials need to be dried before batching. Drying is carried out in the oven according to the drying time and temperature of different raw materials, and the polyvinylidene fluoride resin particle crystals are put into the drying process. Machine, dry at 45°C-50°C for 30-40min for standby;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com