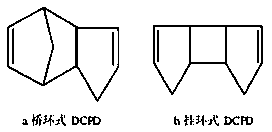

Method for preparing tricyclodecanedicarboxylic acid with dicyclopentadiene as raw material

A technology for cyclodecanedicarboxylic acid and dicyclopentadiene, which is applied in the field of carbonylation reaction to prepare carboxylic acid, can solve problems such as the production technology of tricyclodecanedicarboxylic acid is still in its infancy, and achieves easy amplification and industrial application, reaction Mild conditions and the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The cobalt, rhodium and manganese trimetals supported by α-alumina modified by phosphine ligands are prepared, and the specific steps are as follows:

[0060] A: Dissolve 20ml of aluminum isopropoxide in 14ml of ethanol, and heat to 60°C with stirring to obtain an ethanol solution of aluminum isopropoxide;

[0061] B: 3g manganese nitrate, 0.3g cobalt chloride and 0.3g rhodium trichloride are dissolved in 10ml distilled water, join in the ethanolic solution of aluminum isopropoxide prepared in step A, then add 5ml concentrated nitric acid and 5ml water The mixed solution is aged at 60°C for 24h; then roasted at 400°C for 6h in an air atmosphere in a muffle furnace to obtain cobalt-rhodium-manganese oxide supported on α-alumina;

[0062] C: Reduce the α-alumina-supported cobalt-rhodium-manganese oxide prepared in step B at 400°C in hydrogen for 4 hours, cool to room temperature, then roast at 400°C in air for 6 hours, and finally reduce it again in hydrogen at 400°C 4 h...

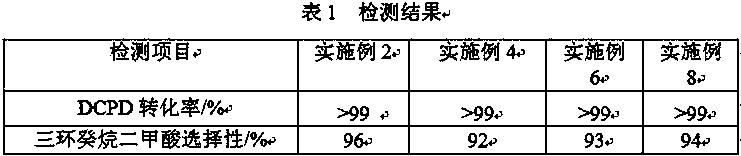

Embodiment 2

[0065] The preparation of tricyclodecane dicarboxylic acid, concrete steps are:

[0066] Introduce 5 g of dicyclopentadiene (DCPD), 0.15 g of triphenylphosphine-modified α-alumina-supported cobalt-rhodium-manganese trimetal and 20 ml of tetrahydrofuran into a 200 ml autoclave, Airtight, filled with air and synthesis gas (volume ratio 1 / 1) to 5 MPa, the reaction temperature is 160 ° C, the reaction pressure is 8 MPa, and the reaction is 6 hours to obtain tricyclodecanedicarboxylic acid.

Embodiment 3

[0068] The cobalt, rhodium and manganese trimetals supported by α-alumina modified by phosphine ligands are prepared, and the specific steps are as follows:

[0069] A: Dissolve 28ml of aluminum isopropoxide in 14ml of ethanol, and heat to 80°C with stirring to obtain an ethanol solution of aluminum isopropoxide;

[0070] B: 3g manganese nitrate, 0.3g cobalt chloride and 0.3g rhodium trichloride are dissolved in 10ml distilled water, join in the ethanolic solution of aluminum isopropoxide prepared in step A, then add 5ml concentrated nitric acid and 5ml water The mixed solution was aged at 80°C for 72h, and then calcined at 600°C for 3h in an air atmosphere in a muffle furnace to obtain cobalt-rhodium-manganese oxide supported on α-alumina;

[0071] C: Reduce the α-alumina-supported cobalt rhodium manganese oxide prepared in step B at 600°C in hydrogen for 2h, cool to room temperature, then roast at 600°C in air for 3h, and finally reduce at 600°C in hydrogen for 2h , to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com