Method for preparing stannous octoate by pressurizing

A technology of stannous octoate and isooctanoic acid, applied in the directions of carboxylate preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of difficult large-scale application, high production cost, high solution temperature, and achieve good product quality , The effect of reducing production cost and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

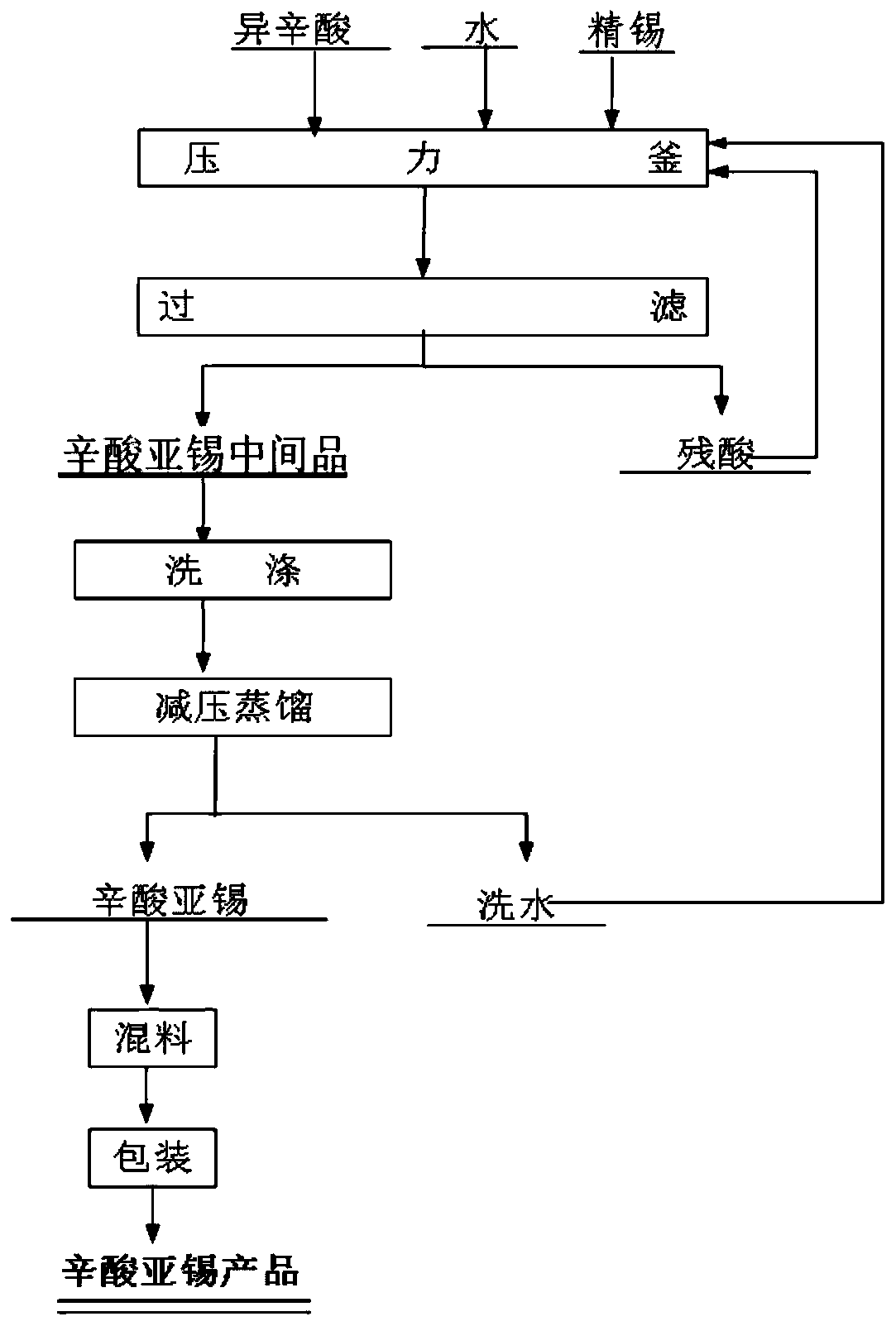

Method used

Image

Examples

Embodiment 1

[0019] The method for preparing stannous octoate under pressure, in a 3L autoclave, add 1.4L of water, then add 660g of liquid isooctanoic acid, start stirring and then add 500g of tin flower, the liquid-solid mass ratio is 4:1. Cover the autoclave, heat and control the reaction pressure to 1.0MPa (the reaction pressure is the pressure of water vapor pressure and the hydrogen generated by the reaction), the reaction temperature is 180±5°C, and the reaction time is 6 hours. After the reaction, three layers of substances appear , the lowermost layer is solid stannous octoate (intermediate product), the middle layer is water, and the uppermost layer is unreacted isooctanoic acid. The liquid and solid are separated, and the solution is settled again to release the intermediate stannous octoate in the lower layer. The aqueous solution used in the closed reaction is only the carrier, and the residual acid and the aqueous solution are added with isooctanoic acid and then returned to ...

Embodiment 2

[0027] Pressurize the method for preparing stannous octoate, in 3L autoclave, add 1.4L water, add 440g isooctanoic acid again, open and stir and add 300g tin flower again, liquid-solid mass ratio is 6:1, autoclave capping, heating and Control the reaction pressure to 1.2MPa, the reaction temperature is 155±5°C, and the reaction time is 5 hours. After the reaction, the liquid and solid are separated, and the solution is settled again. Then return to the autoclave and continue to pressurize to prepare stannous octoate.

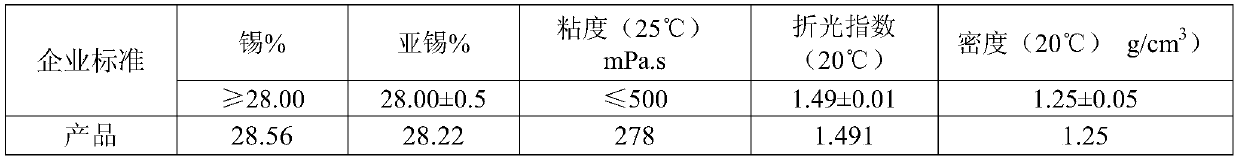

[0028] Add water and wash the stannous octoate intermediate product, and the supernatant is taken away, and the stannous octoate after washing is added in the distillation still to remove moisture, obtains 640g stannous octoate product, and product reaches following product quality standard.

[0029]

Embodiment 3

[0031] The method for preparing stannous octoate under pressure, in a 3L autoclave, add 1.8L water, then add 220g isooctanoic acid, start stirring and then add 200g tin powder, the liquid-solid mass ratio is 10:1, the autoclave is covered, heated and Control the reaction pressure to 1.5MPa, the reaction temperature is 200±5°C, and the reaction time is 4 hours. After the reaction, the liquid and solid are separated, and the solution is settled again. The intermediate product of stannous octoate is released from the lower layer. Then return to the autoclave and continue to pressurize to prepare stannous octoate.

[0032] Add water and wash the stannous octoate intermediate product, and the supernatant is taken away, and the stannous octoate after washing is added in the distillation still to remove moisture, obtains the 300g stannous octoate product, and the product reaches the following product quality standards.

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com