Non-biochemical process for treating printing and dyeing wastewater

A kind of printing and dyeing sewage, non-biochemical technology, applied in water/sewage treatment, chemical instruments and methods, textile industry wastewater treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

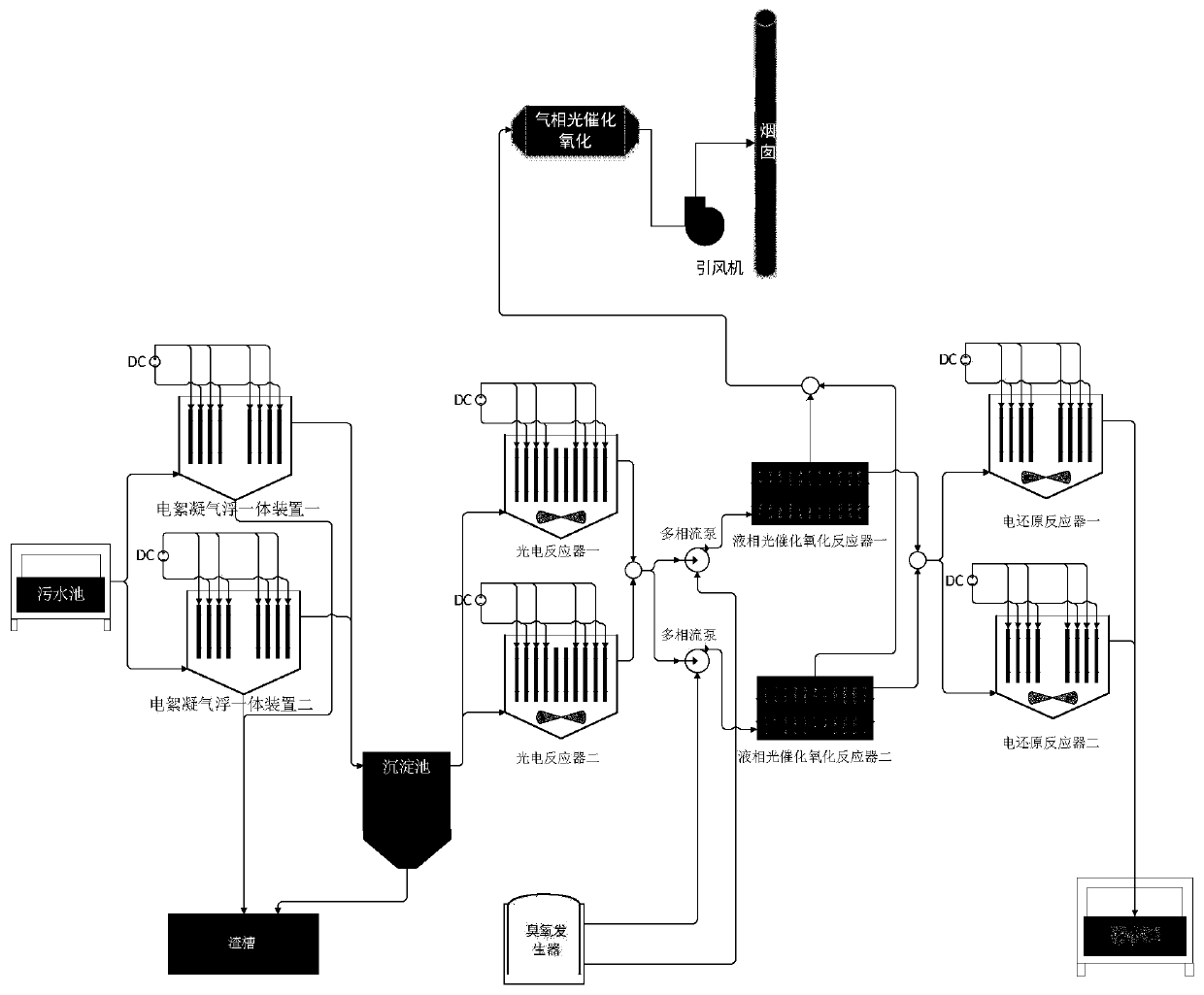

[0123] Such as figure 1 A kind of non-biochemical method treatment printing and dyeing sewage process shown, described process comprises the steps:

[0124] Step S1: leachate electrocoagulation air flotation sedimentation treatment;

[0125] Step S2: the leachate treated in step S1 is treated by photolysis and electrochemical reaction;

[0126] Step S3: The leachate treated in step S2 is treated by an electric field cooperative photocatalytic oxidation reaction. After the test reaches the standard, the non-biochemical treatment of the leachate is completed. If the test does not meet the standard, enter step S4: the leachate treated in step S3 After the electrochemical reduction reaction treatment, the non-biochemical treatment of the leachate is completed;

[0127] Step S5: The exhaust gases generated in steps S1, S2, and S3 are collected and then processed by gas-phase photocatalytic oxidation, or when step S4 is included, the exhaust gases generated in steps S1, S2, S3, an...

Embodiment 2

[0157] A non-biochemical process for treating printing and dyeing sewage, characterized in that the process comprises the following steps:

[0158] Step S1: leachate electrocoagulation air flotation sedimentation treatment;

[0159] Step S2: the leachate treated in step S1 is treated by photolysis and electrochemical reaction;

[0160] Step S3: The leachate treated in step S2 is treated by an electric field cooperative photocatalytic oxidation reaction. After the test reaches the standard, the non-biochemical treatment of the leachate is completed. If the test does not meet the standard, enter step S4: the leachate treated in step S3 After the electrochemical reduction reaction treatment, the non-biochemical treatment of the leachate is completed;

[0161] Step S5: The exhaust gases generated in steps S1, S2, and S3 are collected and then processed by gas-phase photocatalytic oxidation, or when step S4 is included, the exhaust gases generated in steps S1, S2, S3, and S4 are c...

Embodiment 3

[0191] A non-biochemical process for treating printing and dyeing sewage, characterized in that the process comprises the following steps:

[0192] Step S1: leachate electrocoagulation air flotation sedimentation treatment;

[0193] Step S2: the leachate treated in step S1 is treated by photolysis and electrochemical reaction;

[0194] Step S3: The leachate treated in step S2 is treated by an electric field cooperative photocatalytic oxidation reaction. After the test reaches the standard, the non-biochemical treatment of the leachate is completed. If the test does not meet the standard, enter step S4: the leachate treated in step S3 After the electrochemical reduction reaction treatment, the non-biochemical treatment of the leachate is completed;

[0195] Step S5: The exhaust gases generated in steps S1, S2, and S3 are collected and then processed by gas-phase photocatalytic oxidation, or when step S4 is included, the exhaust gases generated in steps S1, S2, S3, and S4 are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com