Chitosan hydrogel, and preparation method and application thereof

A technology of chitosan and thiolated chitosan, which is applied in the direction of additive processing, can solve the problems of reduced printability and application range, low mechanical strength and toughness of the colloid, and slow curing speed, and can achieve biodegradation speed. Adjustable, adjustable mechanical strength, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

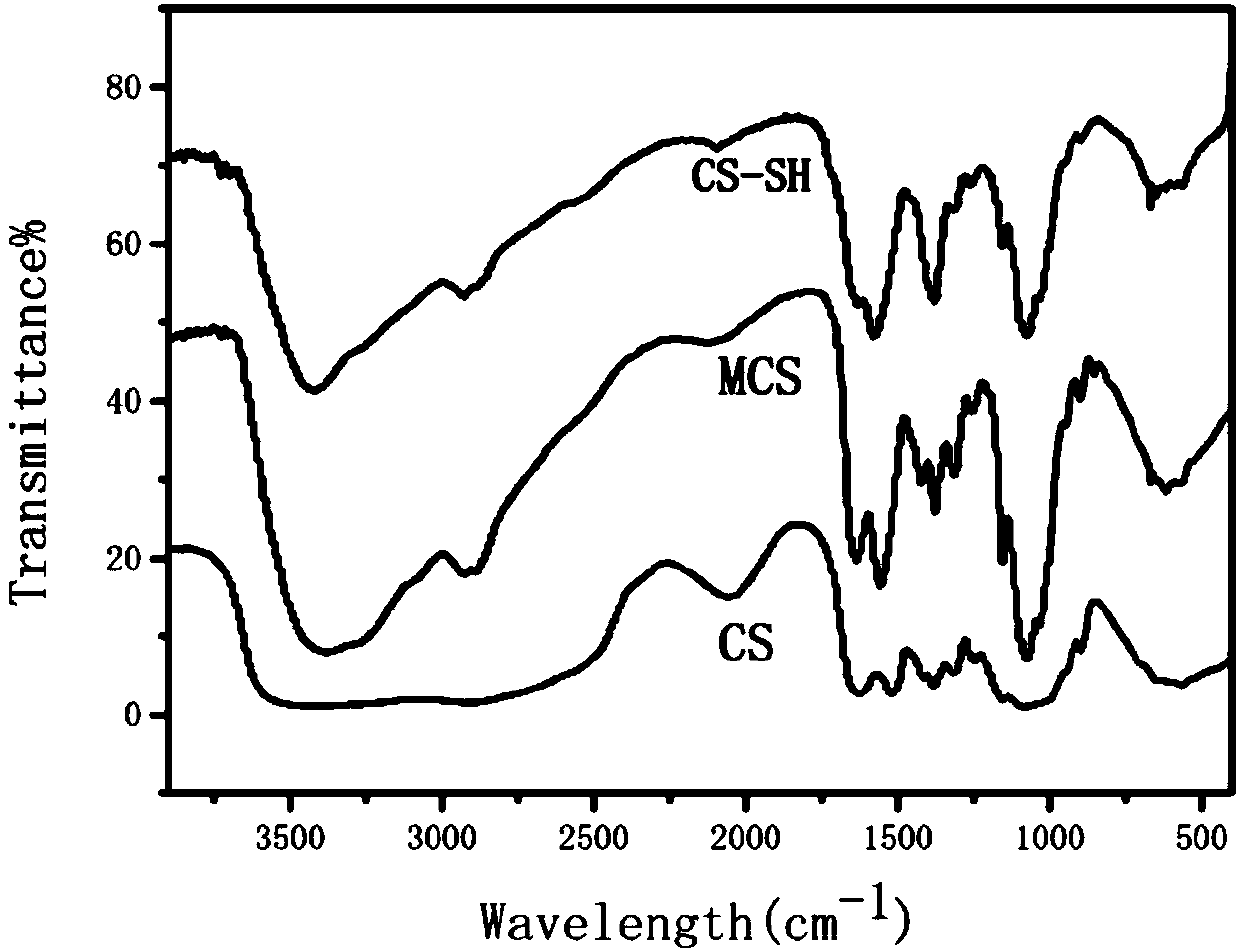

[0022] A preparation method of chitosan hydrogel, comprising: carrying out Michael addition reaction of α-β unsaturated acylated chitosan and thiolated chitosan; the general formula of α-β unsaturated acylated chitosan for: The general formula of thiolated chitosan is:

[0023] Among them, R 1 Remove the residues of amino groups for chitosan macromolecules; R 2 is a hydrogen atom, an alkyl group or an alkylene group; R 3 is carbonyl, carboxyl, ester, amide, alkyl or substituted alkyl; R 4 is an alkylene or substituted alkylene.

[0024] Chitosan (CS), also known as chitosan, is the product of deacetylation of chitin and is a widely used natural polysaccharide. Chitosan is the only alkaline polysaccharide in nature. The free amino nitrogen atom on its molecular chain has a pair of unshared electron pairs, which can combine with a hydrogen proton, so that chitosan becomes a positively charged polyelectrolyte. Chitosan has good biocompatibility, biodegradability, bacteri...

Embodiment 1

[0073] The preparation method of the chitosan hydrogel provided by the present embodiment comprises:

[0074](1) Accurately weigh 1.5 g of chitosan and dissolve it in acetic acid with a mass fraction of 0.01%. After being substantially uniformly dissolved under the action of a magnetic stirrer, place it in an ultrasonic oscillator for 30 minutes of sonication. Accurately weigh 1.8 g of the acylating reagent (maleic anhydride), add 5 ml of acetone to dissolve it completely. Add the dissolved acylation reagent into the chitosan acetic acid solution at a uniform speed and slowly, and stir for about 20 minutes under a magnetic stirrer to make it fully mixed. Transfer the uniformly mixed liquid into a 150ml round-bottomed flask, place it in a heat-collecting magnetic stirrer, set the temperature at 40°C, and heat at a constant temperature for 2 hours. Dialysis was performed for three days after the reaction stopped, and the dialysate was changed every 5 hours. Freeze-drying for ...

Embodiment 2

[0080] The preparation method of the chitosan hydrogel provided by the present embodiment comprises:

[0081] (1) Accurately weigh 1.5 g of chitosan and dissolve it in acetic acid with a mass fraction of 0.01%. After being substantially uniformly dissolved under the action of a magnetic stirrer, place it in an ultrasonic oscillator for 30 minutes of sonication. Accurately weigh 1.8 g of the acylating agent (β-methacrylic acid), add 5 ml of acetone to dissolve it completely. Add the dissolved acylation reagent into the chitosan acetic acid solution at a uniform speed and slowly, and stir for about 20 minutes under a magnetic stirrer to make it fully mixed. Transfer the uniformly mixed liquid into a 150ml round-bottomed flask, place it in a heat-collecting magnetic stirrer, set the temperature at 40°C, and heat at a constant temperature for 2 hours. Dialysis was performed for three days after the reaction stopped, and the dialysate was changed every 5 hours. Freeze-drying for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com