Organic photoelectric detector and manufacturing method thereof

A photodetector and organic technology, applied in photovoltaic power generation, electric solid-state devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of material failure, easy carbonization of organic materials, high cost, etc., to reduce production costs, low cost, avoid The effect of negative electrode recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

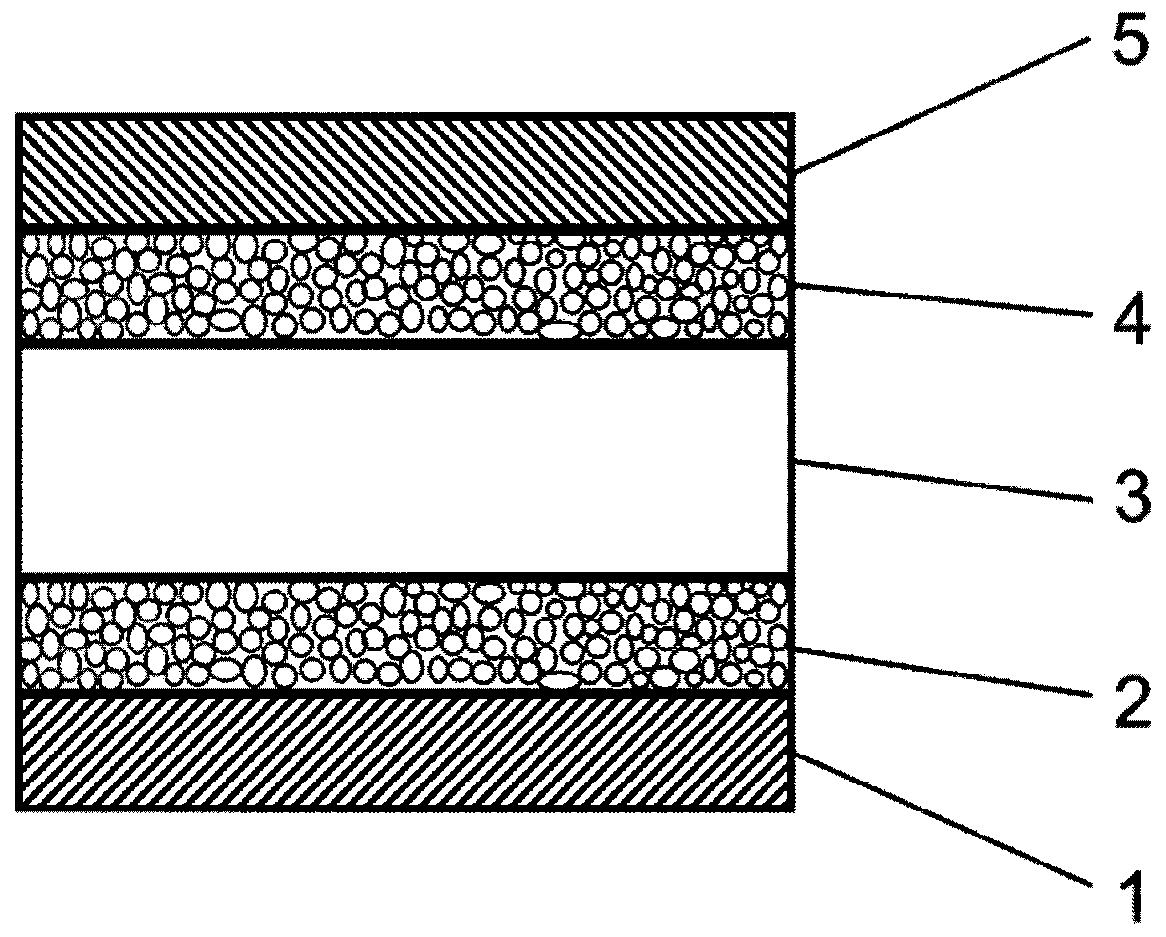

[0038] In this example, see figure 1 , an organic photodetector, sequentially composed of a substrate, a negative electrode ITO conductive film layer 1, a first functional layer 2, an organic active working layer 3, a second functional layer 4, and a positive electrode layer 5 to form a multilayer device structure. The active working layer 3 is made of a bulk heterojunction mixed material, which absorbs the detection light and forms photogenerated carriers;

[0039] The first functional layer 2 serves as an electron transport layer and as a hole blocking layer;

[0040] The second functional layer 4 acts as a hole transport layer and as an electron blocking layer;

[0041] The first functional layer 2, the organic active working layer 3, and the second functional layer 4 all use a solution method, using a nanoparticle dispersion containing a volatile solvent, and then preparing a nanomaterial film by a spin coating method, and then preparing a thin film of nanomaterials at no...

Embodiment 2

[0055] This embodiment is basically the same as Embodiment 1, especially in that:

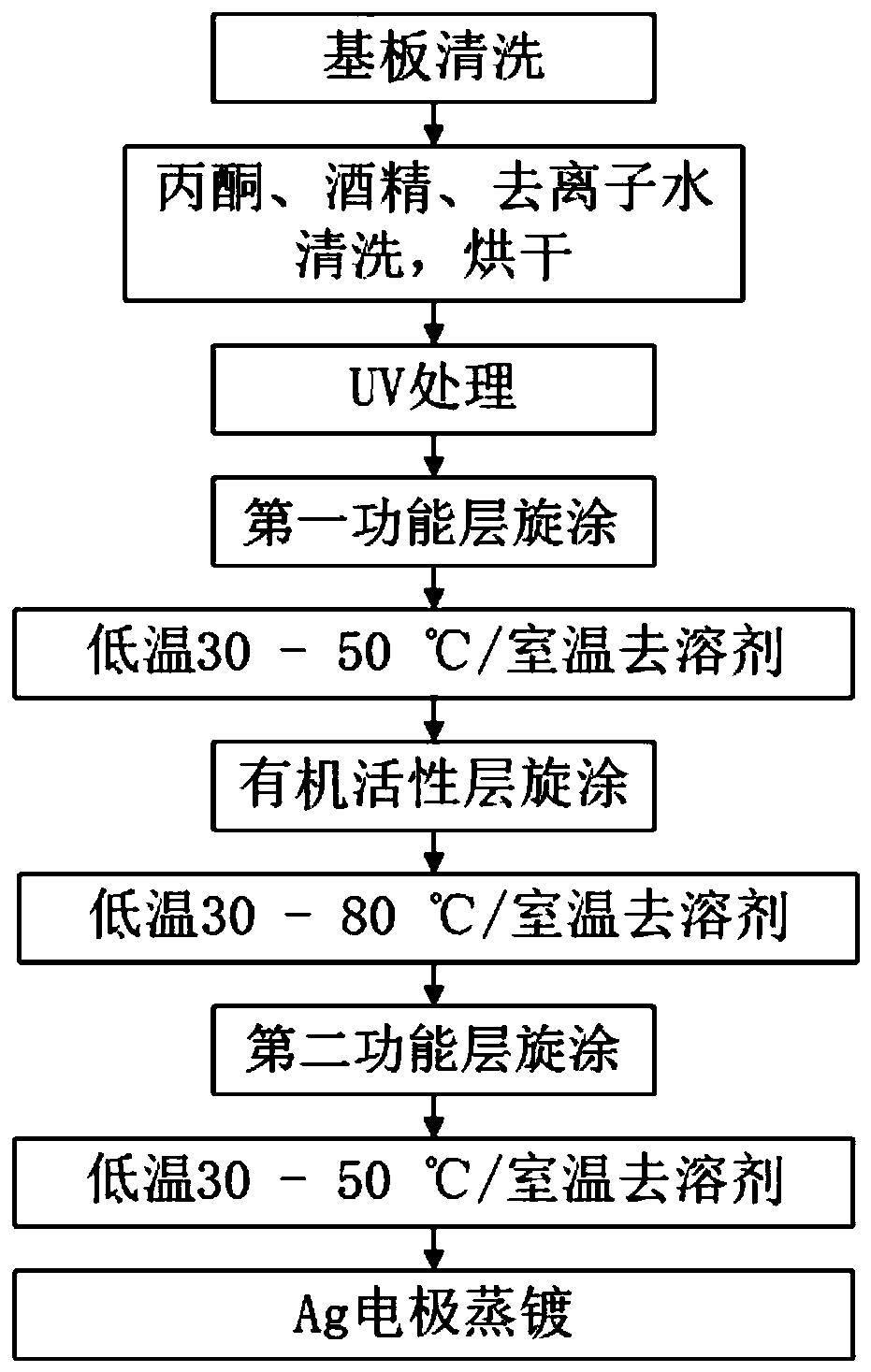

[0056] In this embodiment, a method for preparing an organic photodetector of this embodiment includes the following steps:

[0057] a. Preparation of negative electrode ITO conductive film layer:

[0058] Through the sputtering process, the nano-silver particle material layer is deposited on the ITO glass substrate or the ITO flexible substrate, and then the acetone, alcohol, and deionized water are respectively ultrasonicated for 10 minutes, then dried, and then subjected to UV treatment to strengthen the surface of the substrate. Combined with the nano-silver particle material layer to prepare the negative electrode ITO conductive film layer;

[0059] b. Preparation of the first functional layer:

[0060] By means of spin coating, the nanoparticle dispersion liquid containing volatile solvent is used as the coating material, and the nanometer film layer is coated on the nanosilver particle...

Embodiment 3

[0069] This embodiment is basically the same as the previous embodiment, and the special features are:

[0070] In this embodiment, a method for preparing an organic photodetector of this embodiment includes the following steps:

[0071] a. Preparation of negative electrode ITO conductive film layer:

[0072] Through the sputtering process, the nano-silver particle material layer is deposited on the ITO glass substrate or the ITO flexible substrate, and then the acetone, alcohol, and deionized water are respectively ultrasonicated for 10 minutes, then dried, and then subjected to UV treatment to strengthen the surface of the substrate. Combined with the nano-silver particle material layer to prepare the negative electrode ITO conductive film layer;

[0073] b. Preparation of the first functional layer:

[0074] By the way of spin coating, adopt the nano particle dispersion liquid that contains volatile solvent as coating material, on the nano silver particle material layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com