Preparation method of activated carbon dynamically coated with hydrophobic material

A hydrophobic material, activated carbon technology, applied in separation methods, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of poor hydrophobicity of activated carbon, plugging pores of activated carbon, affecting hydrophobic performance, etc., to improve adsorption performance. , mild conditions, and the effect of enhancing the hydrophobicity of the activated carbon surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

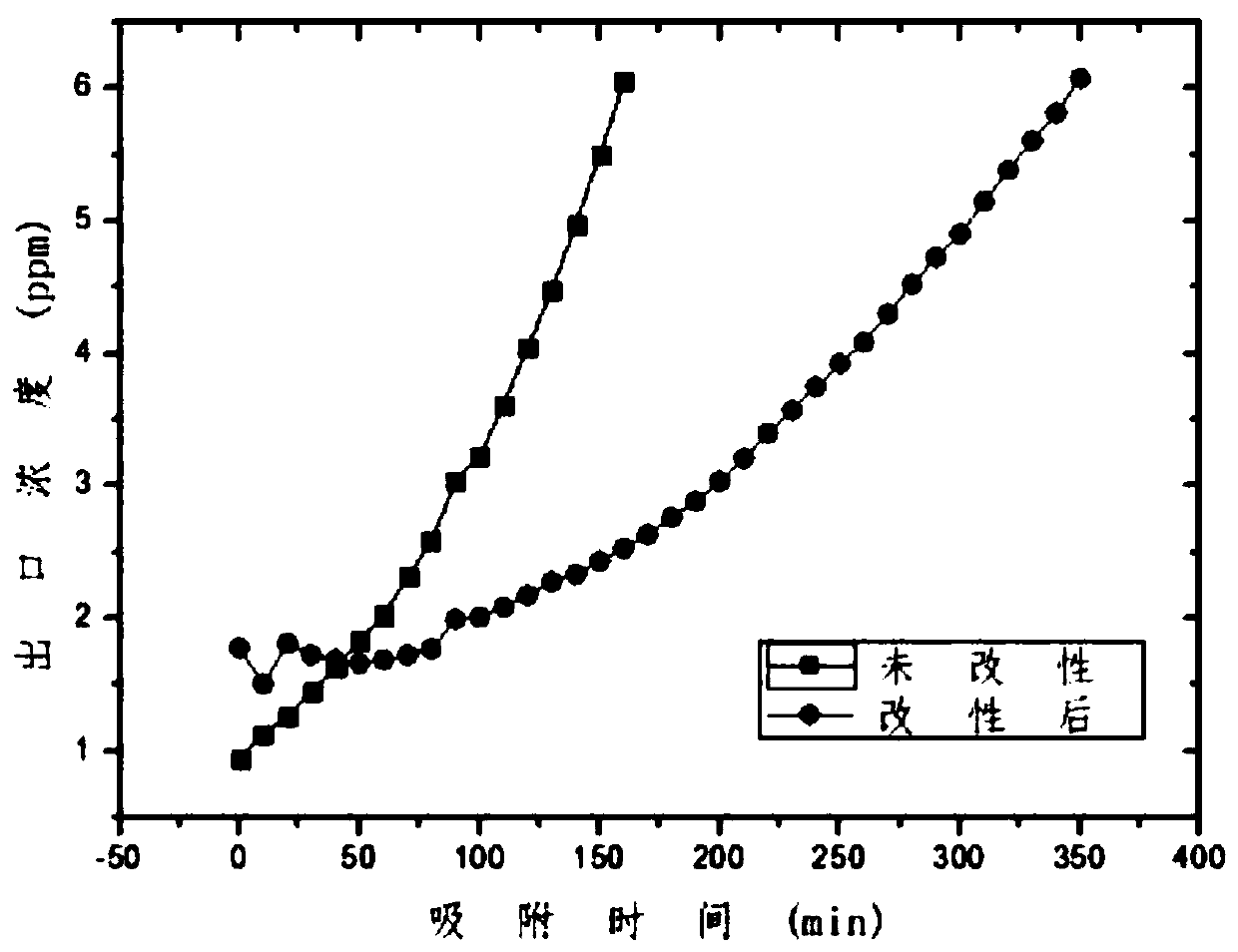

Embodiment 1

[0030] Honeycomb activated carbon cut into 2*2*2mm was heated and dried in a blast drying oven at 120°C for 6 hours, and the dried samples were placed in a desiccator for later use. In an ice-water bath, dissolve methacrylate (7g) and initiator dibenzoyl peroxide (0.07g) in tetrahydrofuran (50ml), add 3.5ml of water, stir and mix with a magnetic stirrer for 4h as a resin Polymerization liquid. Take 0.5ml of resin polymer liquid to vapor-phase-deposit on the surface of activated carbon, transfer the activated carbon obtained after vapor-phase deposition into a blast dryer and dry for 2 hours to obtain the hydrophobic methacrylate modified activated carbon adsorbent. Unmodified gac is under initial concentration 120ppm (with 5% of initial concentration as adsorption breakthrough point), 80% relative humidity, the adsorption capacity to toluene vapor adsorption breakthrough point is 16.6mg / g, after modification The adsorption capacity of activated carbon to toluene vapor adsorpt...

Embodiment 2

[0032] Honeycomb activated carbon cut into 2*2*2mm was heated and dried in a blast drying oven at 120°C for 6 hours, and the dried samples were placed in a desiccator for later use. In an ice-water bath, dissolve methacrylate (7g) and initiator dibenzoyl peroxide (0.28) in N,N-dimethylformamide (70ml), add 7ml of water, and use a magnetic stirrer Stir and mix in medium for 4h as resin polymerization solution. Take 0.5ml of resin polymer liquid to gas-phase deposit on the surface of activated carbon, transfer the coated activated carbon into a blast dryer and dry for 4 hours to obtain a hydrophobic methacrylate modified activated carbon adsorbent. Unmodified gac is under initial concentration 120ppm (with 5% of initial concentration as adsorption breakthrough point), 80% relative humidity, the adsorption capacity to toluene vapor adsorption breakthrough point is 16.6mg / g, after modification The adsorption capacity of activated carbon to toluene vapor adsorption breakthrough po...

Embodiment 3

[0034] The honeycomb activated carbon cut into 2*2*2mm was heated and dried in a blast drying oven at 120°C for 6 hours, and the sample was placed in a desiccator after drying. In an ice-water bath, methacrylate (7g) and initiator dibenzoyl peroxide (0.15g) were dissolved in ethyl acetate (50ml), and 5ml of water was added, stirred and mixed for 4h with a magnetic stirrer as Resin Polymer Liquid. Take 0.5ml of resin polymer liquid to gas-phase deposit on the surface of activated carbon, transfer the obtained activated carbon into a blast dryer and dry for 6 hours to obtain the hydrophobic acrylate modified activated carbon adsorbent. Unmodified gac is under initial concentration 120ppm (with 5% of initial concentration as adsorption breakthrough point), 80% relative humidity, the adsorption capacity to toluene vapor adsorption breakthrough point is 16.6mg / g, after modification The adsorption capacity of activated carbon to toluene vapor adsorption breakthrough point under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com