Preparation method of a photo-driven carbon nanotube helical fiber composite driver

A technology of fiber composite materials and carbon nanotubes, applied in the field of material science, can solve problems such as low resin content, impact on driving performance, and unrealized photo-induced actuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Specific Embodiment 1: This embodiment provides a method for preparing a carbon nanotube helical fiber composite driver driven by light, and the method is carried out according to the following steps:

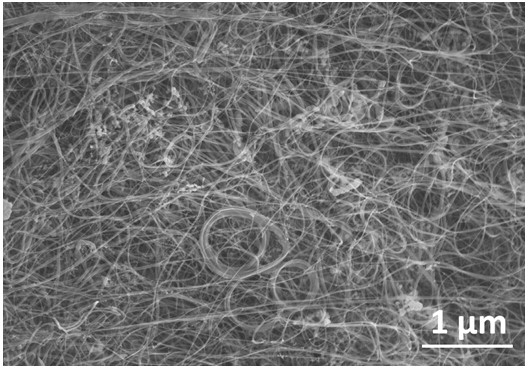

[0031] Step 1, the preparation of carbon nanotube film:

[0032]The method of chemical vapor deposition is used to prepare the carbon nanotube thin film. The specific steps are as follows: the catalyst ferrocene and the growth promoter sublimated sulfur are dissolved in the liquid carbon source xylene to obtain a mixed solution of the catalyst, the growth promoter and the carbon source , wherein: the preparation ratio of ferrocene, sublimated sulfur and xylene is to dissolve 0.1-40g of ferrocene powder and 0.002-1g of sublimated sulfur per 10-500mL of xylene; a precision injection pump (model LSP02-B, purchased From Baoding Lange Constant Current Pump Co., Ltd.), the mixed solution of catalyst, growth promoter and carbon source was injected into the preheating zone of a ...

specific Embodiment approach 2

[0042] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the ferrocene and sublimed sulfur are dissolved in liquid carbon source xylene by ultrasonic means, and the ultrasonic time is 10-300min, and the ultrasonic power 10~200 kHz; the temperature of the preheating zone is 150~500°C, the temperature of the reaction zone is 900~1300°C; the H 2 / Ar carrier gas, H 2 The volume ratio of Ar and Ar is 1:1~4, and the carrier gas flow rate is 400~2000 mL / min.

specific Embodiment approach 3

[0043] Specific embodiment three: the difference between this embodiment and specific embodiment one is: in step one, H 2 / Ar carrier gas brings the carbon source, catalyst and growth promoter into the reaction zone of the tube furnace for reaction, specifically: cracking occurs first, and the cracked carbon atoms and carbon atom clusters are under the action of the iron catalyst cracked by ferrocene , grow into carbon nanotubes, and the carbon nanotubes produced by the reaction are quickly taken out of the growth area by the mixed flow of argon and hydrogen, and are evenly deposited in the product collection area to form a large-area carbon nanotube film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com