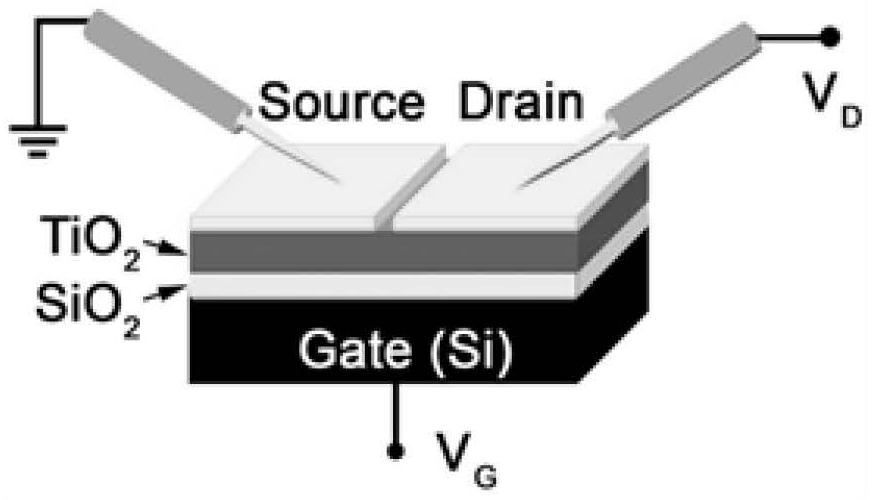

tio 2 Thin film preparation method, photodetector device and preparation method thereof

A photodetector and photodetection technology, applied in electrical components, semiconductor devices, circuits, etc., can solve problems such as difficulty in obtaining TiO single crystal thin films, inability to control spectral response, and weak performance of photodetection devices, so as to reduce oxygen defects , reduce the effect of recombination and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Embodiments of the present invention propose a crystallized TiO 2 The preparation method of thin film, comprises the following steps:

[0037] S1, using nitrogen as the load gas, alternately feeding titanium source and water vapor, and obtaining atomic-level TiO generated by the reaction on the oxide layer of the substrate 2 , the reaction temperature is 220-300°C, and the reaction pressure is 10-20 Pa;

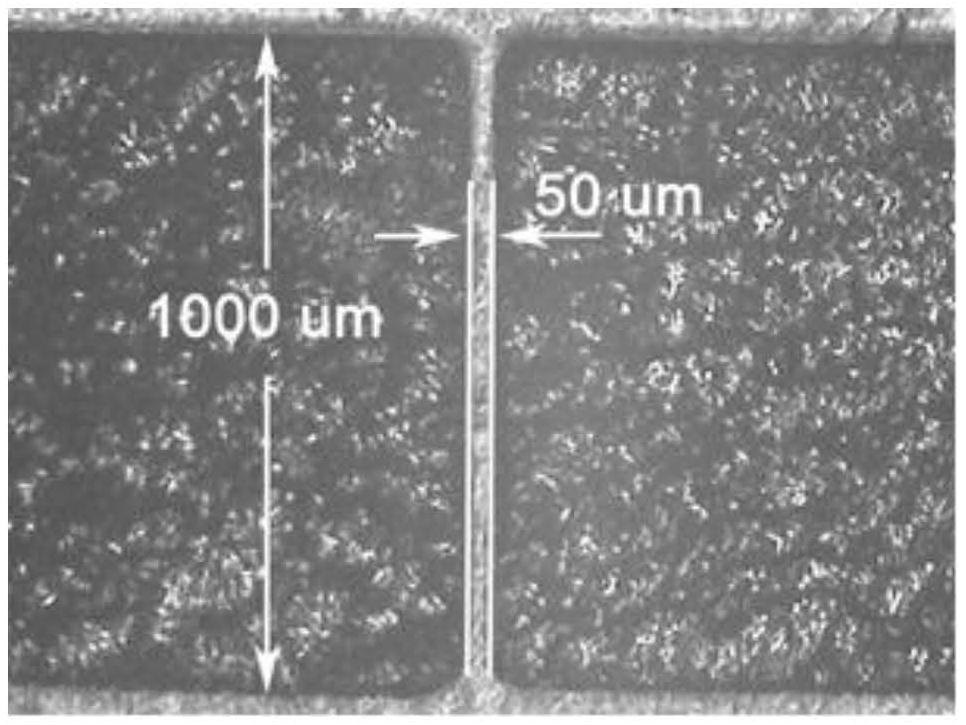

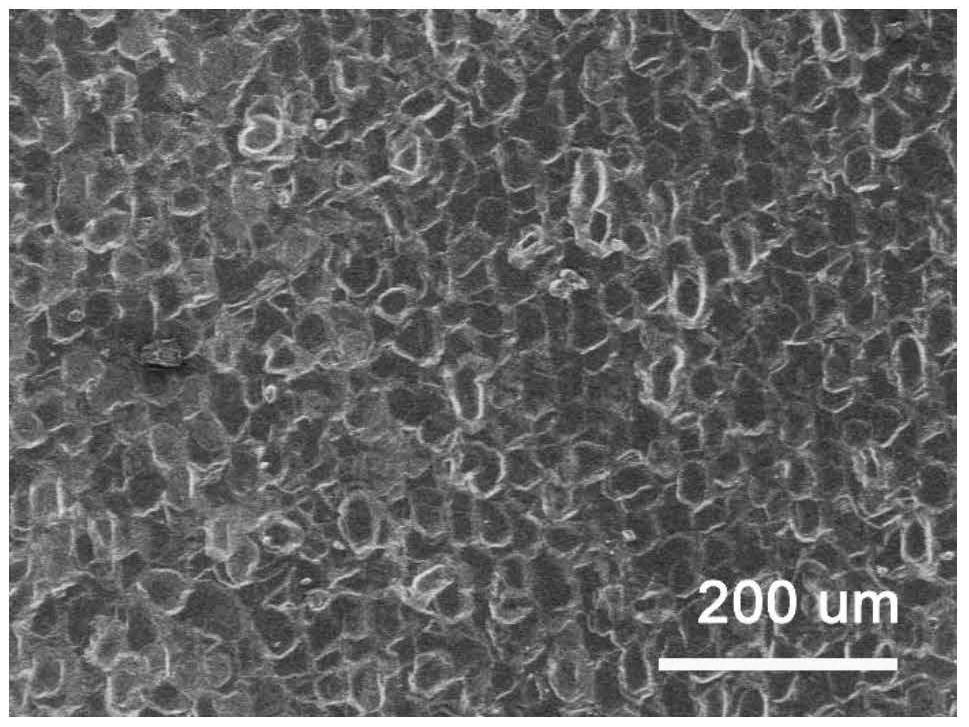

[0038] S2, TiO obtained from S1 2 The substrate is calcined in an oxygen-containing atmosphere at a temperature of 400-800°C, that is, crystallized fish-scale TiO is obtained on the substrate. 2 film, such as image 3 shown;

[0039] Wherein, the titanium source is titanium isooxypropoxide (Ti{OCH(CH 3 ) 2} 4 ), the temperature of the titanium source is 70-80°C;

[0040] The substrate is P-type Si with a silicon oxide layer on one side and Si on the other side.

[0041] In one embodiment, argon is used as a carrier gas, and titanium source and water vapor are ...

experiment example

[0074] Experimental example: Substrate pretreatment: first treat the substrate SiO 2 / P-Si preparation and cleaning. First, use electronic cleaning agent diluent, ethanol, and deionized water for preliminary washing; then use ammonia water, hydrogen peroxide, and deionized water to form a mixed solution at a ratio of 1:1:5, and put the silicon wafer into the mixed solution for ultrasonic cleaning After 15 minutes, use deionized water for multiple ultrasonic cleaning to remove the washing residue until the washing liquid after washing is detected as neutral by pH test paper; then use concentrated hydrochloric acid, hydrogen peroxide, and deionized water according to the ratio of 1:1:5 Ratio to form a mixed solution, put the silicon chip into the mixed solution for ultrasonic cleaning for 15 minutes, and then use deionized water to ultrasonically clean it several times to remove the washing residue until the washing solution after washing is detected as neutral by pH test paper;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com