Modified starch and preparation method and application thereof

A starch and modification technology, used in textiles and papermaking, reinforcing agent addition, paper, etc., can solve the problems of difficult wastewater treatment, high equipment and process requirements, and easy over-gelatinization of starch products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0351] Example 1 Effects of cationic starch binder cetylpyridine hydrochloride (Code C7) on starch dissolution and fiber surface adsorption after reacting with starch

[0352] Experimental steps: (1) take cornstarch sample and prepare 7% "standard starch solution"; (2) take an appropriate amount of standard starch solution and add deionized water to dilute to the required concentration of starch solution; (3) take the prepared concentration Put 500mL of starch solution in a beaker, and put it into a 45°C constant temperature water bath, and equilibrate to the specified temperature; (4) Add C7 according to the required concentration, and react for 60 minutes to obtain a modified starch solution; (5) Sampling and centrifuging ( 4000x g) for 5 minutes, take the supernatant to test the starch concentration; (6) add bleached chemical pulp (BKP) to the remaining modified starch solution according to a solid concentration of 1%, and keep stirring for 10 minutes; (7) after the reaction...

Embodiment 2

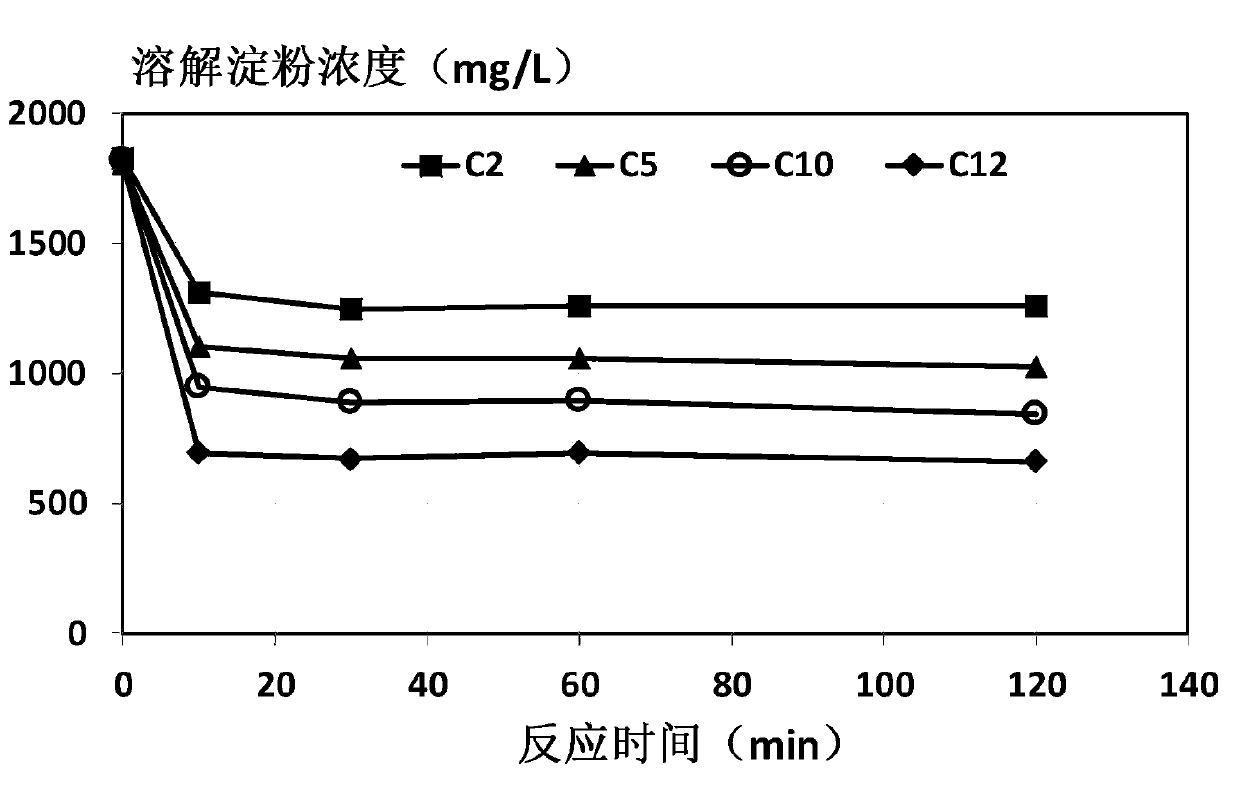

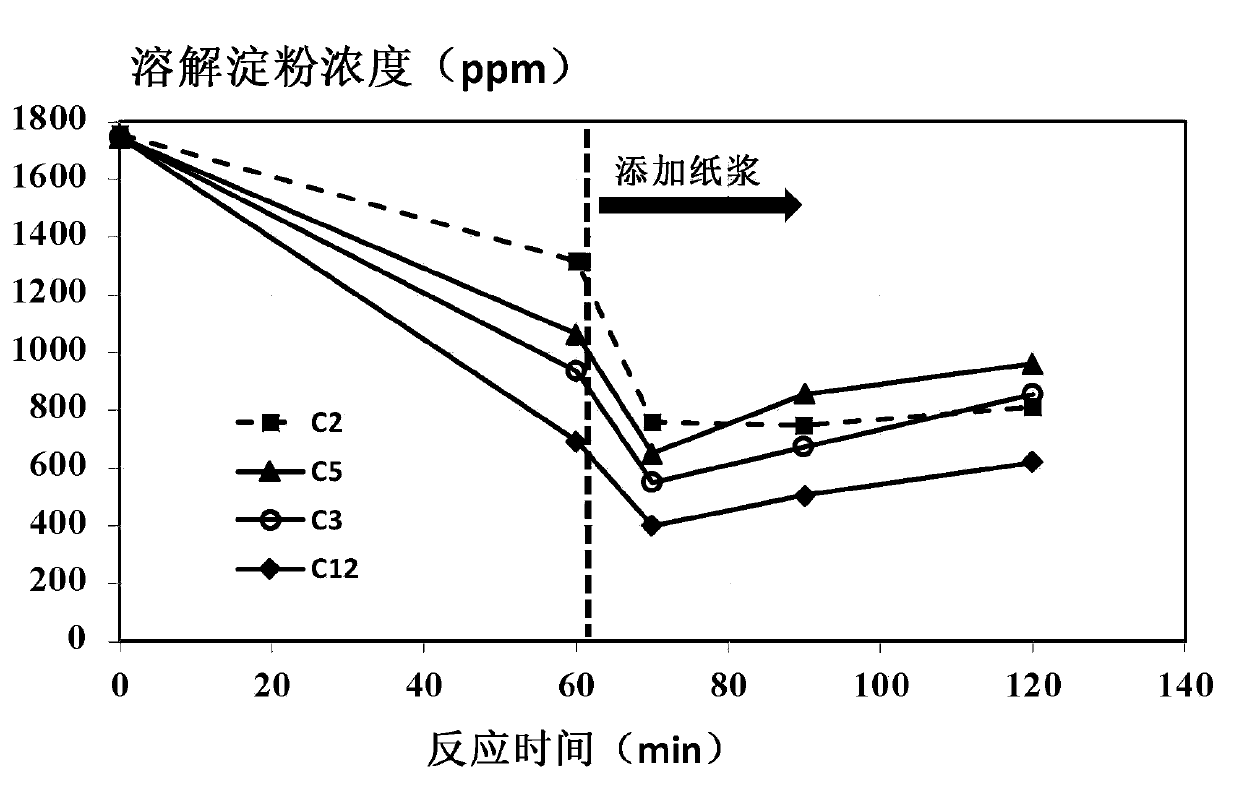

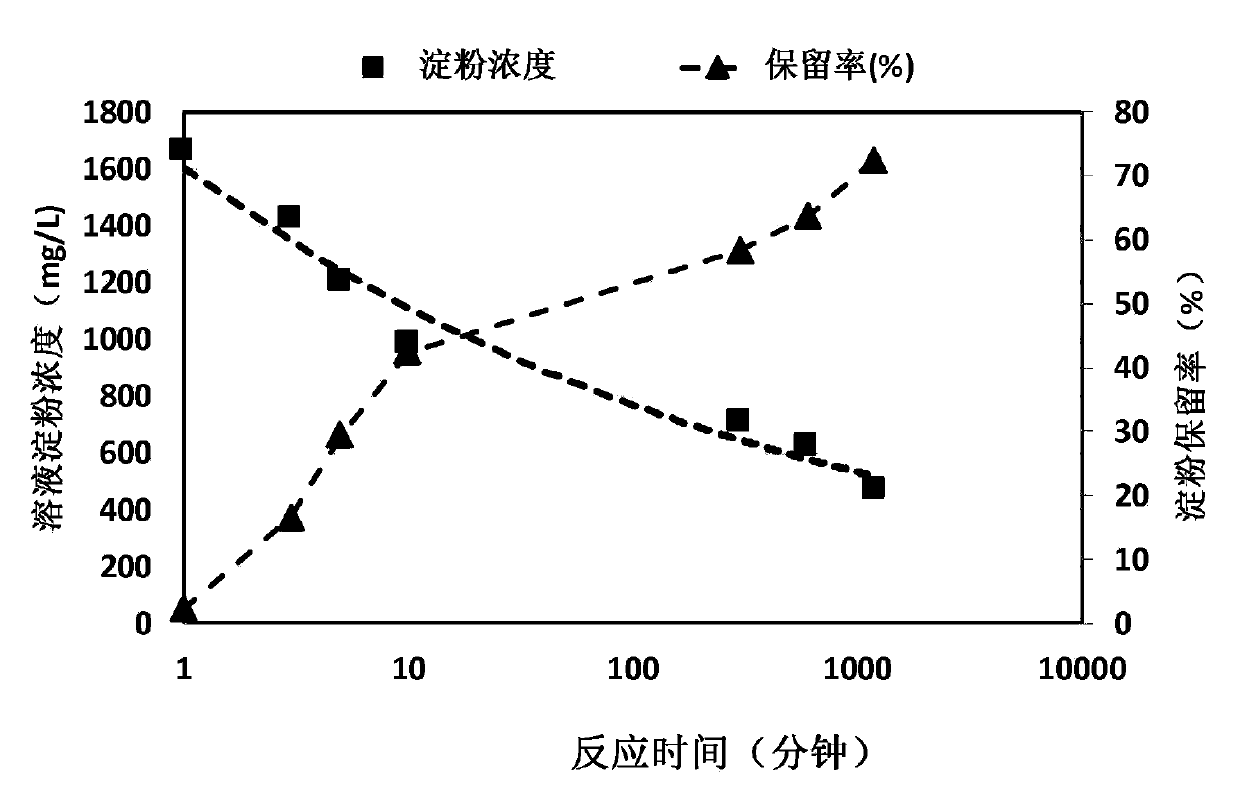

[0358] Embodiment 2 The influence of reaction time on starch binding reaction

[0359]Experimental steps of starch reaction: (1) take corn starch sample and prepare 7% "standard starch solution"; (2) take appropriate amount of standard starch solution and dilute it with deionized water to a starch concentration of about 1800mg / L (or other required concentration) (3) Take 500mL of the prepared starch solution or OCC white water, place it in a beaker, and put it into a 45°C constant temperature water bath, and equilibrate to the specified temperature; (4) Add 30mg / L starch binder as required, When the reaction reaches 1, 3, 5, 10, 30, 60, 90, 120, 300, 600 and 1200 minutes, the sample is centrifuged (4000x g) for 5 minutes, and the supernatant is taken to test the starch content and COD concentration;

[0360] The test procedure of starch adsorption reaction time: steps (1)-(4) are the same as above, (5) when the starch reaction reaches 60 minutes, add 3% chemical pulp (BKP) acc...

Embodiment 3

[0365] Example 3 Effect of Reaction Temperature on Starch Binding Reaction and Adsorption Effect of Modified Starch

[0366] Experimental steps: (1) Take corn starch samples to prepare 7% "standard starch solution"; (2) Take an appropriate amount of standard starch solution and add deionized water to dilute to a starch concentration of about 600mg / L; (3) Take the prepared starch solution 500mL, placed in a beaker, and put into a constant temperature water bath with the required test temperature preset, and equilibrated to the specified temperature; (4) According to the requirements of the test, add 30mg / L cationic starch binder C7 and react for 60 minutes to obtain Modified starch solution; (5) sample centrifugation (4000x g) for 5 minutes, get the supernatant to test starch content and COD concentration; (6) add chemical pulp (BKP ) (Note: The amount of starch binder is equivalent to 1000g / T dry pulp), keep stirring; (7) React for 10 minutes, take the slurry and centrifuge (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Burst index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com