Black phosphorus / reduced graphene oxide composite electrode, preparation method thereof, and flexible lithium ion battery including the composite electrode

A lithium-ion battery and graphene composite technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., to achieve the effects of low energy consumption, high yield, and enhanced mechanical flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Material

[0061]The following reagents and solvents were used without further purification: polyacrylonitrile (PAN, Mw=150,000, Sigma-Aldrich), N,N-dimethylformamide (DMF, 99.8%, Sigma-Aldrich), hydrochloric acid (37%, Fisher), nitric acid (69-72%, Fisher), N-methylpyrrolidone (NMP), PVDF-HFP (average Mw ~ 455,000, Sigma-Aldrich), sulfuric acid (98%, Fisher), hydrogen peroxide (30% , Fisher), potassium permanganate (97%, Sigma-Aldrich), vanadium pentoxide (>98%, Sigma-Aldrich), polydimethylsiloxane (Sigma-Aldrich), acetone (Fisher).

[0062] characterize

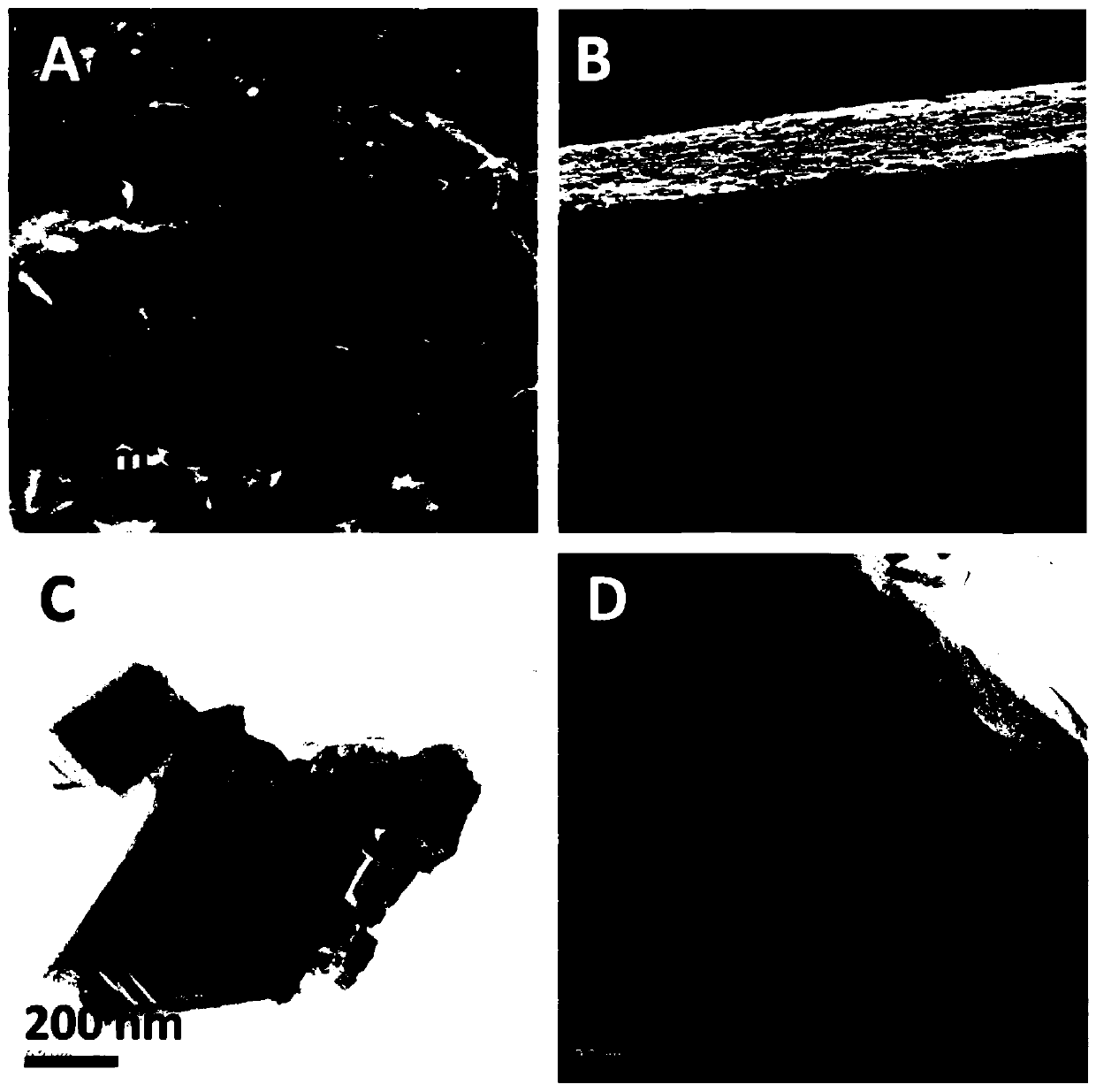

[0063] The morphology was characterized using scanning electron microscopy (SEM, JEOL7100F) and transmission electron microscopy (TEM, JEOL2010). Electrochemical performance was measured on a battery test system (Land 2001CT).

[0064] Manufacturing method

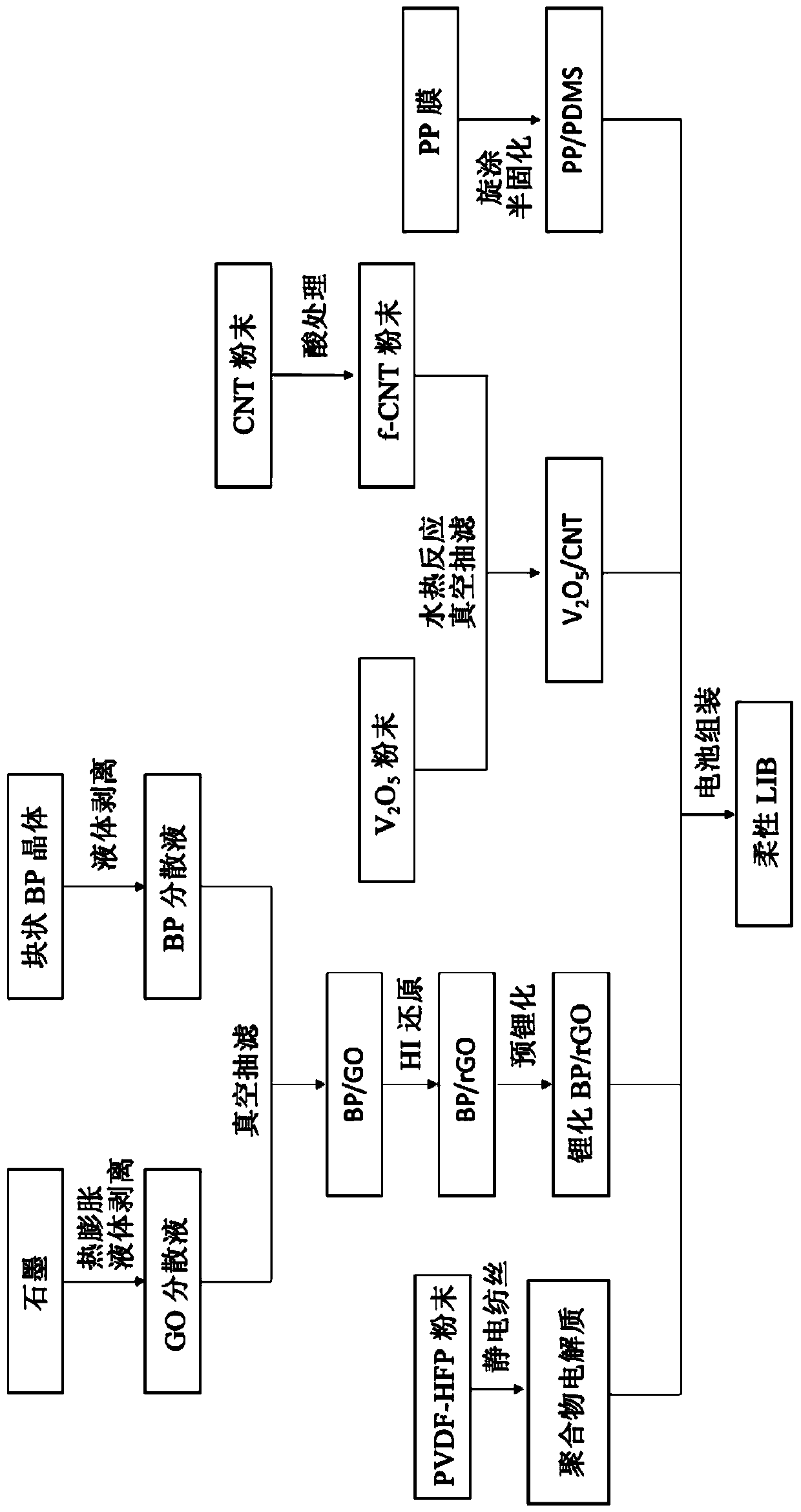

[0065] In Example 1, the BP / rGO electrode was prepared by vacuum filtration and mild reduction of the BP / GO dispersion. Synthesis of V by hydrothermal...

Embodiment 2

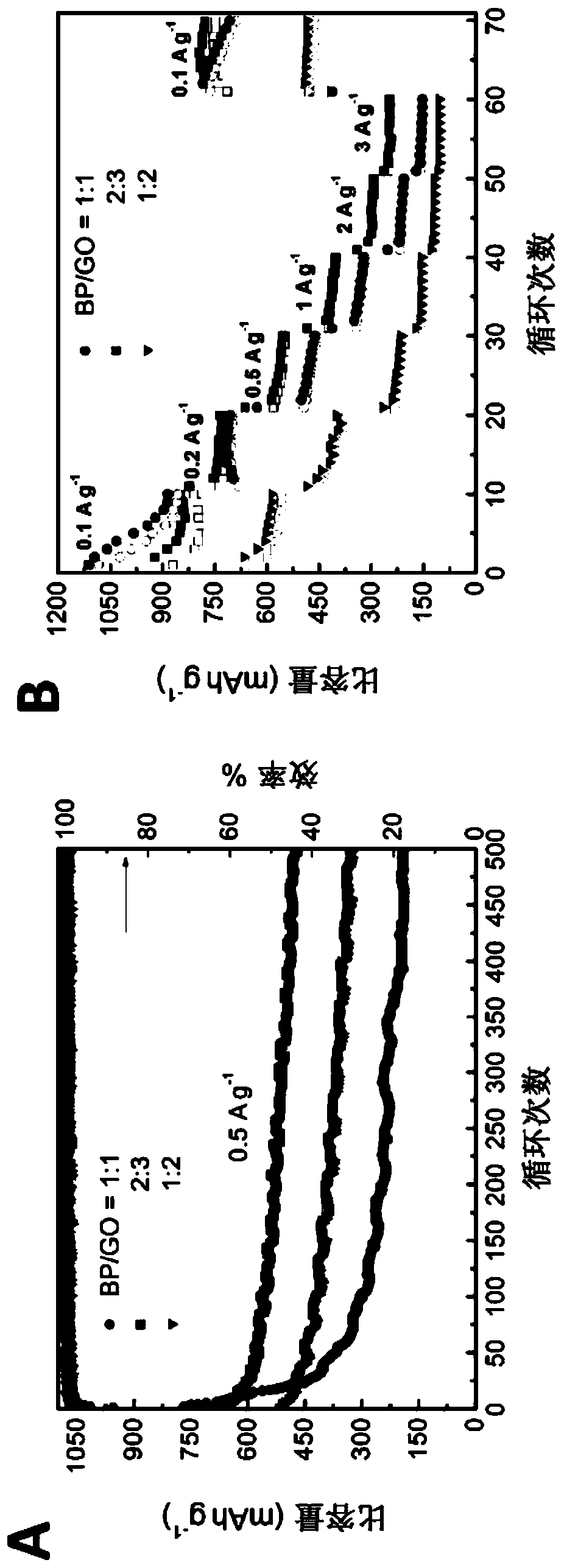

[0079] Prepare flexible lithium-ion battery in a manner similar to Example 1, the difference is: change the amount of black phosphorus sheet dispersion and graphene oxide sheet to make the black phosphorus sheet and the quality of graphene oxide sheet in the black phosphorus sheet dispersion The ratio is 1:1. Then, in a manner similar to Example 1, the cycle performance of the prepared BP / graphene negative electrode was tested.

Embodiment 3

[0081] Prepare flexible lithium-ion battery in a manner similar to Example 1, the difference is: change the amount of black phosphorus sheet dispersion and graphene oxide sheet to make the black phosphorus sheet and the quality of graphene oxide sheet in the black phosphorus sheet dispersion The ratio is 1:2. Then, in a manner similar to Example 1, the cyclability of the prepared BP / graphene negative electrode was tested.

[0082] image 3 The cycle and rate performance test results according to Examples 2 and 3 are given, and the results show that the BP / rGO negative electrodes with a BP / GO ratio of 1:1 and 1:2 can provide better cycle performance and specific capacity, namely , the BP / rGO anode with a BP / GO ratio of 1:2 maintained a specific capacity of 477mAh g-1 after 500 cycles, and the average Coulombic efficiency was 99.6%; and the BP / rGO with a BP / GO ratio of 1:2 The negative electrode maintains a specific capacity of 329mAh·g-1 after 500 cycles, and the average Coul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com