Large-scale energy-saving gradient air separation process

An air separation and energy-saving technology, applied in the direction of nitrogen purification/separation, oxygen preparation, oxygen/ozone/oxide/hydroxide, etc., can solve the problems of large investment and energy consumption, loss of oxygen pressure potential energy, etc., and achieve improvement Scale, reduction of separation energy consumption, effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The zeolite molecular sieve treated in this embodiment is a lithium A molecular sieve, the pressure swing adsorption separation device is a vacuum pressure swing adsorption, and the carbon molecular sieve pressure swing adsorption tower is a radial pressure swing adsorption tower:

[0030] The process is as follows:

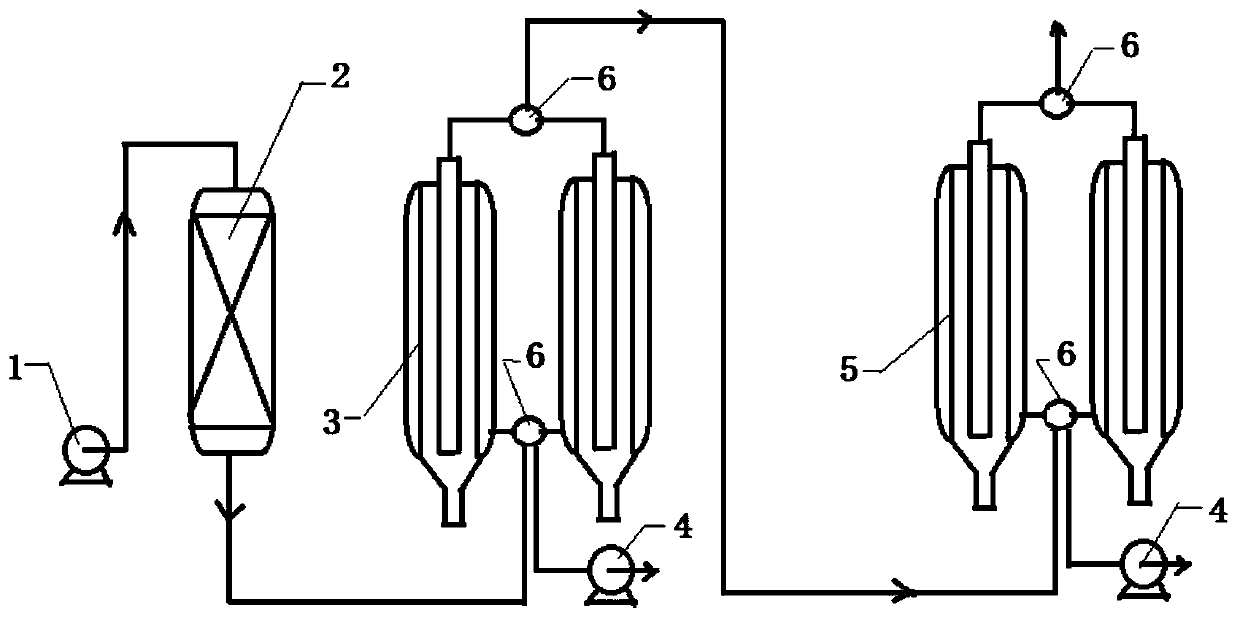

[0031] After the filtered air is pressurized by the fan 1 and pretreated by the dehydration and decarbonation adsorption tower 2, the dry and decarbonated pressurized air is first adsorbed and separated by the radial zeolite molecular sieve vacuum pressure swing adsorption tower 3, and the nitrogen is absorbed by the lithium A type Molecular sieve adsorption, 70% of the oxygen-enriched air flows out of the zeolite molecular sieve vacuum pressure swing adsorption tower 3; through the program control valve 6, the zeolite molecular sieve vacuum pressure swing adsorption tower 3 is switched, and the high-purity nitrogen is reduced from the zeolite molecular sie...

Embodiment 2

[0034] The zeolite molecular sieve treated in this embodiment is a 5A molecular sieve, the pressure swing adsorption separation device is a low pressure swing adsorption, and the carbon molecular sieve pressure swing adsorption tower is an axial pressure swing adsorption tower:

[0035] The process is as follows:

[0036] After the filtered air is pressurized by the fan 1 and pretreated by the dehydration and decarbonation adsorption tower 2, the dry and decarbonated pressurized air first passes through the radial zeolite molecular sieve low-pressure pressure swing adsorption tower 3 for adsorption and separation, and the nitrogen is absorbed by the 5A molecular sieve Adsorption, 65% of the oxygen-enriched air flows out of the zeolite molecular sieve low pressure swing adsorption tower 3; the zeolite molecular sieve low pressure swing adsorption tower 3 is switched by the program control valve 6, and the high-purity nitrogen is decompressed from the zeolite molecular sieve pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com