Aluminized steel plate with photo-catalytic activity and excellent corrosion resistance and manufacturing method thereof

A technology of photocatalytic activity and corrosion resistance, applied in chemical instruments and methods, separation methods, anti-corrosion coatings, etc. effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

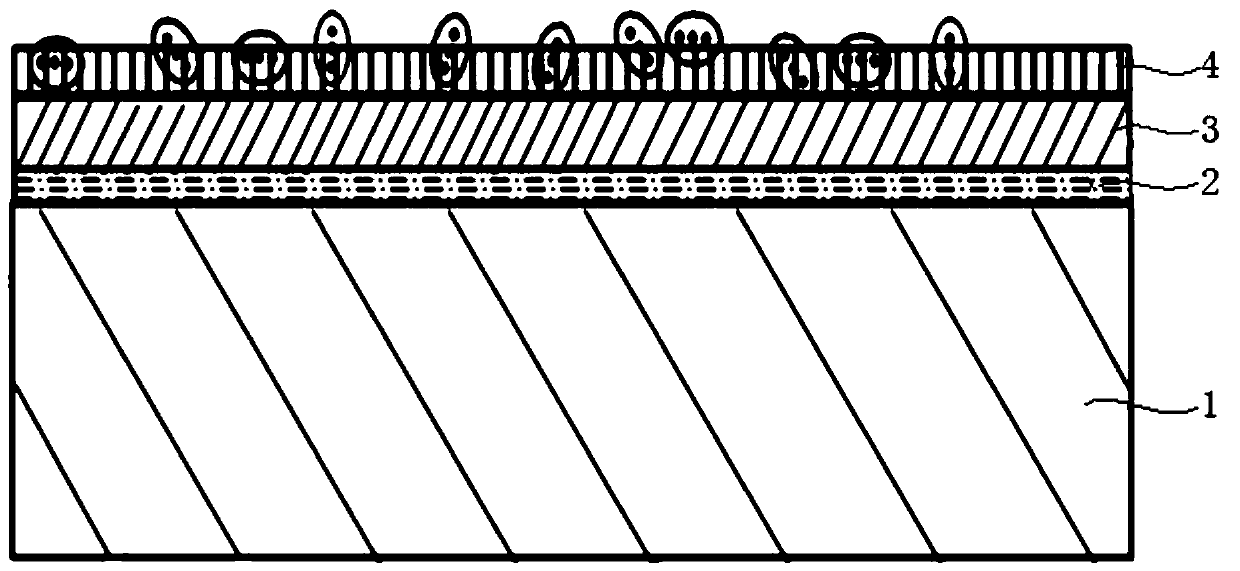

[0050] Such as figure 1 As shown, an aluminized steel sheet 1 with photocatalytic activity and excellent corrosion resistance in Example 1 has: a transparent, translucent or colored passivation film 2 on at least one surface of the aluminized steel sheet 1, laminated A transparent film layer 3 on the surface of the passivation film 2, and a photocatalytic coating 4 laminated on the transparent film layer 3, wherein the transparent film layer 3 contains a silane coupling agent and a silicon modified resin, and the photocatalytic coating 4 contains nitrogen Doped modified titanium dioxide visible light-responsive photocatalytic particles.

[0051] In this embodiment, the hot-dip aluminized steel sheet 1 has a thickness of 0.25 mm and a surface roughness Ra of 0.6 μm.

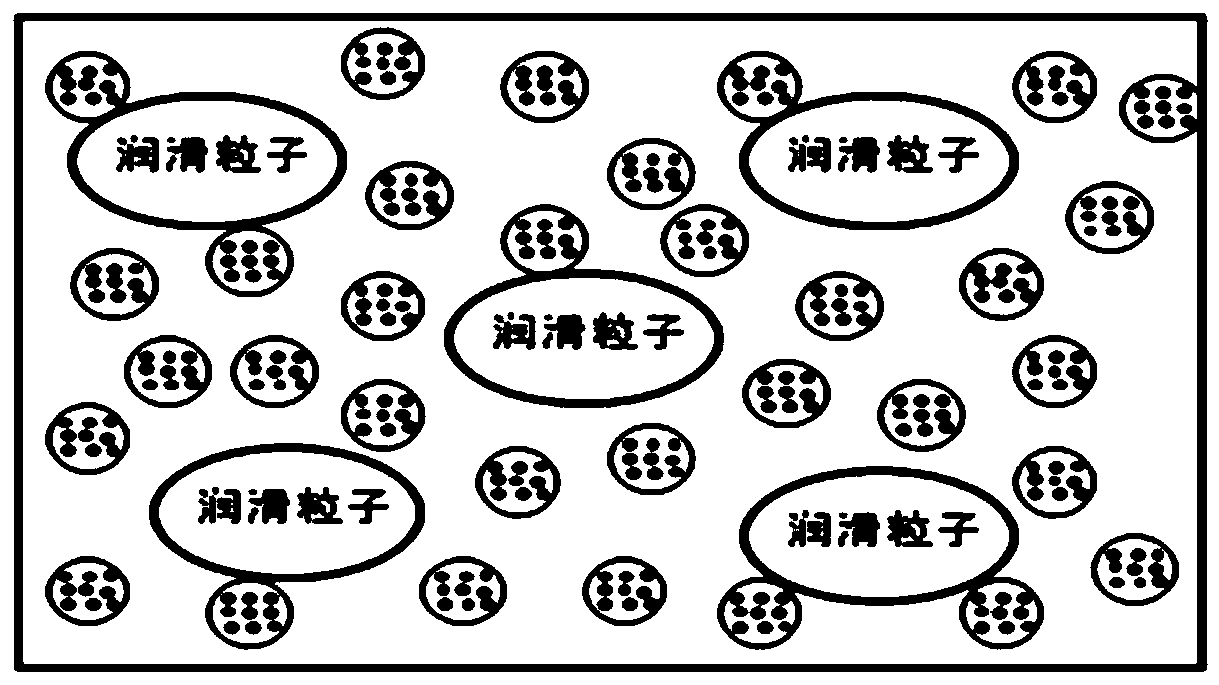

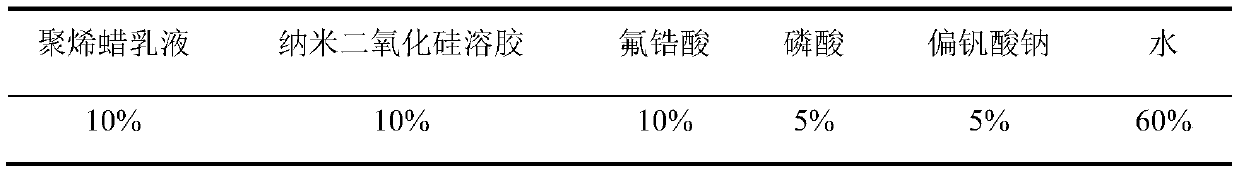

[0052] As shown in Table 1, the passivation film 2 is formed by applying the inorganic-organic composite passivation solution (a-1) to the surface of the aluminum-plated steel plate 1 and drying and curing, and t...

Embodiment 2

[0063] Basically the same as in Example 1, the hot-dip aluminized steel sheet 1 has a thickness of 3.0 mm and a surface roughness Ra of 2.0 μm.

[0064] As shown in Table 3, the passivation film 2 is formed by applying the inorganic-organic composite passivation solution (a-1) to the surface of the aluminum-plated steel plate 1 and drying and curing, and the inorganic-organic composite passivation solution (a-1 ) is made up of 15% organic film-forming substance and 85% inorganic film-forming substance, and described organic film-forming substance is that mass fraction is 15% polyolefin wax emulsion; Described inorganic film-forming substance comprises that mass fraction is 5% nanometer dioxide Silica sol, fluozirconic acid with a mass fraction of 5%, phosphoric acid with a mass fraction of 5%, sodium metavanadate with a mass fraction of 5%, and water with a mass fraction of 65%.

[0065] Table 3 Inorganic-organic composite passivation solution (a-1) composition (%)

[0066] ...

Embodiment 3

[0075] In this embodiment, the hot-dip aluminized steel sheet 1 has a thickness of 2.0 mm and a surface roughness Ra of 1.5 μm.

[0076] As shown in Table 1, the passivation film 2 is formed by applying the inorganic-organic composite passivation solution (a-1) to the surface of the aluminum-plated steel plate 1 and drying and curing, and the inorganic-organic composite passivation solution (a-1 ) is made up of 12% organic film-forming substance and 88% inorganic film-forming substance, and described organic film-forming substance is that mass fraction is 12% polyolefin wax emulsion; Described inorganic film-forming substance comprises that mass fraction is 5% nanometer dioxide Silica sol, fluozirconic acid with a mass fraction of 10%, phosphoric acid with a mass fraction of 15%, sodium metavanadate with a mass fraction of 5%, and water with a mass fraction of 53%.

[0077] Table 5 Inorganic-organic composite passivation solution (a-1) composition (%)

[0078]

[0079] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com