High-efficiency low-resistance PM 2.5 antibacterial mildew-proof filter material and preparation method thereof

A technology of antibacterial and anti-mildew filter materials, which is applied in the field of public environmental protection and sanitation, can solve the problems of limiting the research of PM2.5 anti-bacterial and anti-mildew filter materials, lack of strength, and high filtration resistance, etc., achieve long-lasting anti-bacterial and anti-mold effects, and increase exposure Good effect of area and composite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

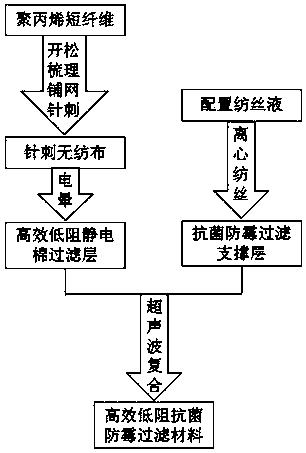

[0044] refer to figure 1 Shown, the preparation method of high-efficiency low-resistance PM2.5 antibacterial mildew-proof filter material comprises the following steps:

[0045] a, PM2.5 preparation of antibacterial and antifungal polymer solution

[0046] After the mass fraction is 15% polylactic acid, 80% dichloromethane solution and 5% average diameter of 10nm silver nanoparticles mixed, the temperature is raised to 40 ° C and mechanically stirred for 3h to obtain a polylactic acid solution containing silver nanoparticles.

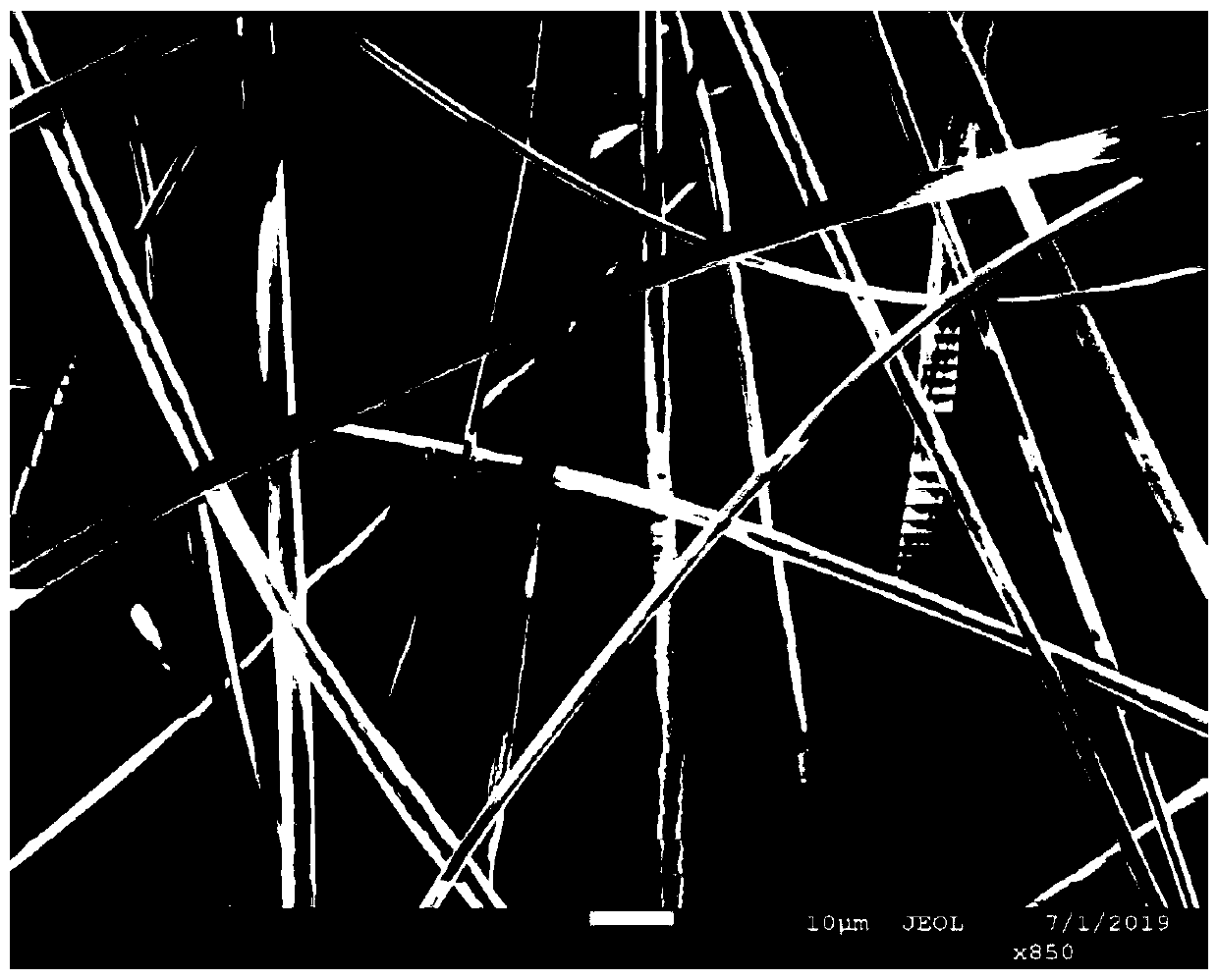

[0047] b. Preparation of PM2.5 antibacterial and mildew-proof filter support layer

[0048]The polylactic acid solution containing nano-silver particles is injected into a centrifugal spinning tank with a spinning hole diameter of 100 μm, and at the same time, the rotating speed of the spinning tank is increased to 4000r / min at a rate of 50r / s, and the polylactic acid solution containing nano-silver particles is Under the action of centrifugal force, ...

Embodiment 2

[0055] According to the above method, the preparation method of high-efficiency and low-resistance PM2.5 antibacterial and mildew-proof filter material comprises the following steps:

[0056] a, PM2.5 preparation of antibacterial and antifungal polymer solution

[0057] After mixing 30% polyurethane by mass fraction, 69% dimethylformamide solution and 1% titanium dioxide nanoparticles with an average diameter of 20nm, the temperature was raised to 60°C and mechanically stirred for 2 hours to obtain a polyurethane solution containing titanium dioxide nanoparticles.

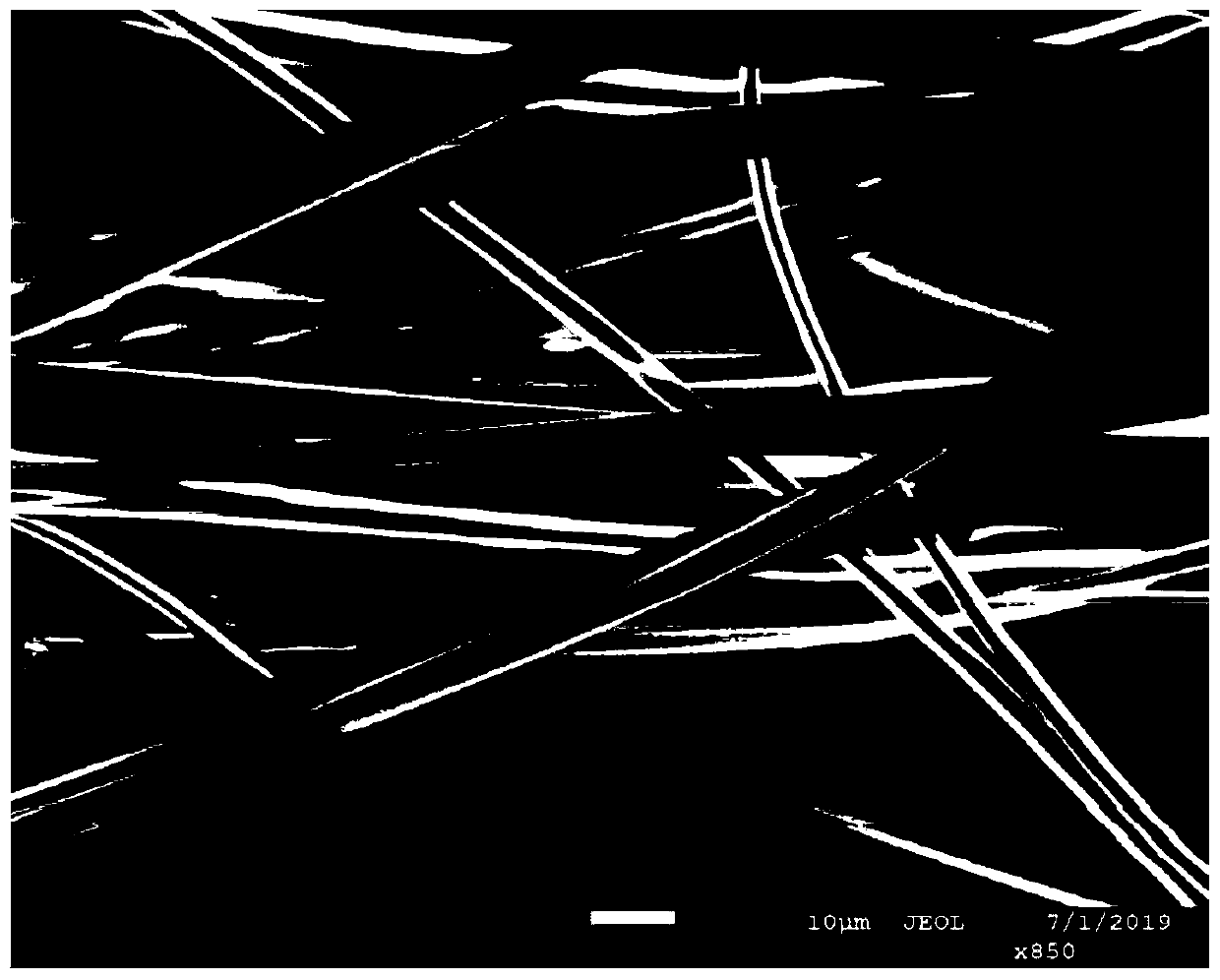

[0058] b. Preparation of PM2.5 antibacterial and mildew-proof filter support layer

[0059] The polyurethane solution containing titanium dioxide nanoparticles is injected into a centrifugal spinning tank with a spinning hole diameter of 300 μm, and at the same time, the speed of the spinning tank is increased to 5000r / min at a rate of 50r / s, and the polyurethane solution containing titanium dioxide nanoparticles i...

Embodiment 3

[0066] According to the above method, the preparation method of high-efficiency and low-resistance PM2.5 antibacterial and mildew-proof filter material comprises the following steps:

[0067] a, PM2.5 preparation of antibacterial and antifungal polymer solution

[0068] After mixing polyacrylonitrile with a mass fraction of 25%, 72% dimethylformamide solution, and 3% zinc oxide nanoparticles with an average diameter of 50nm, the temperature was raised to 50°C and mechanically stirred for 1 hour to obtain zinc oxide-containing nanoparticles. solution of polyacrylonitrile.

[0069] b. Preparation of PM2.5 antibacterial and mildew-proof filter support layer

[0070] The polyacrylonitrile solution containing zinc oxide nanoparticles was injected into a centrifugal spinning pot with a spinning hole diameter of 200 μm, and at the same time, the rotating speed of the spinning pot was increased to 5500 r / min at a rate of 50 r / s, and the polyacrylonitrile solution containing zinc oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wind resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com