Novel nanostructure thin film solar cell and its preparation method

A technology for solar cells and nano-silicon thin films, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problem of unfavorable photoelectric performance, affecting the illumination range of incident light, and low photoelectric conversion efficiency of nano-silicon-amorphous silicon heterojunction solar cells. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention is further illustrated in conjunction with the accompanying drawings and specific embodiments.

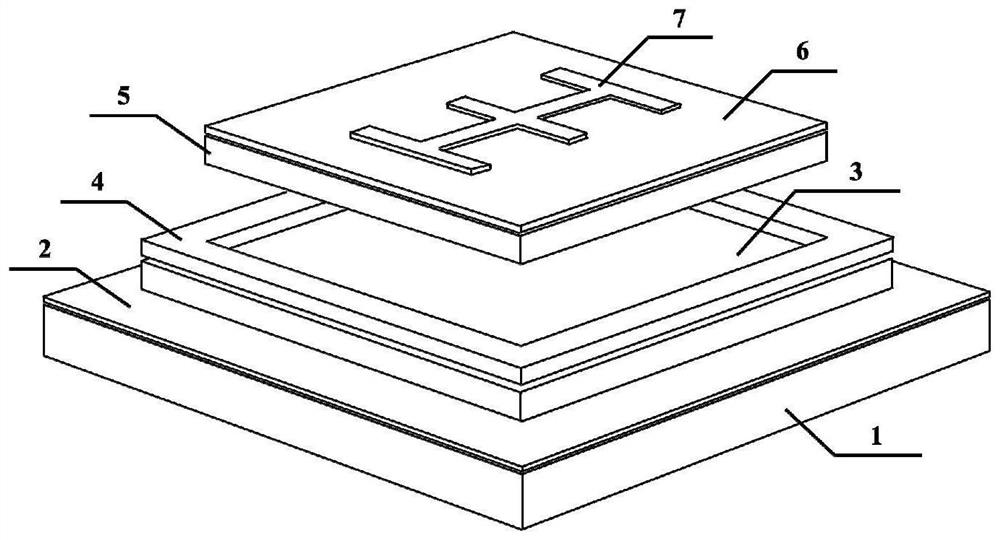

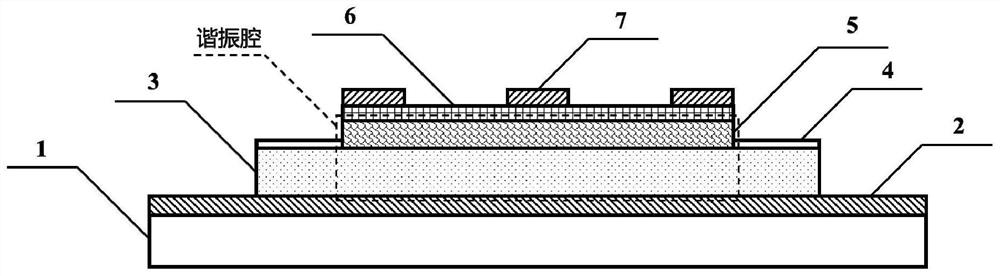

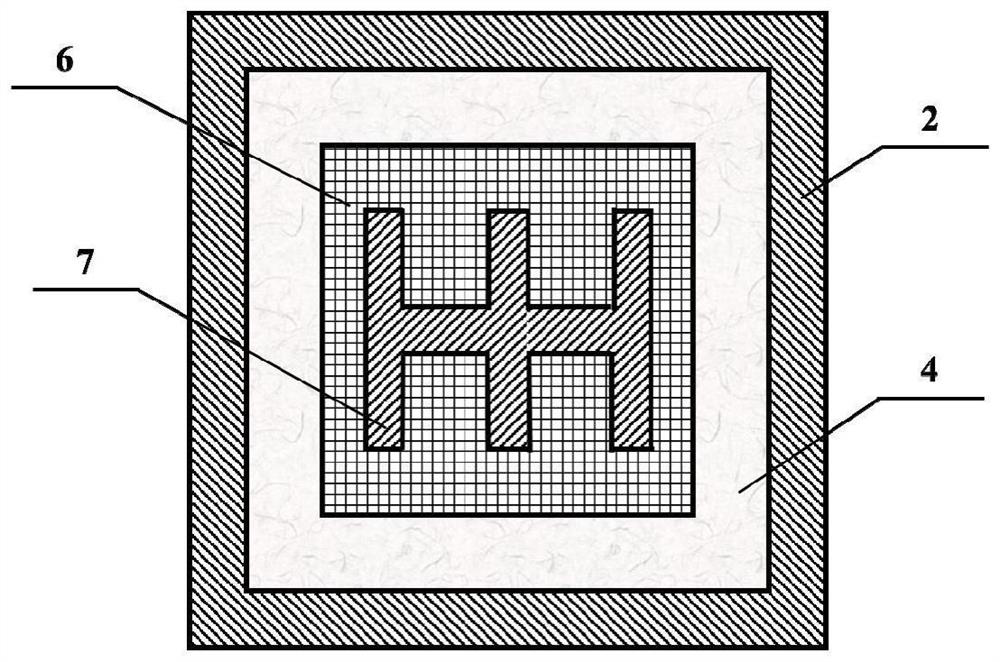

[0028] This example provides a flat thin film solar cell of a graphene junction structure, such as a graphene junction structure, such as Figure 1-3 As shown, a quartz or glass substrate 1, an Al electrode 2, a phosphorus doped amorphous silicon film 3, a silicon carbide film interface layer 4, a boron doped nano film 5, a graphene layer 6, and a graphene layer 6, and a graphene layer 6. AU electrode 7; phosphorus doped amorphous silicon film between the graphene layer and the Al electrode, a boron doped nano film constitutes a nano-resonant cavity. The nano-resonant cavity calculates the thickness of the p-type nanocaricon / N-type amorphous silicon heterojunction by measuring the refractive index and reflectance of graphene, phosphorus doped amorphous silicon, boron doped nanothermium and aluminum. The visible light satisfies the resonance condition in the nanowa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com