Dielectric material for X7R type ceramic capacitor and preparation method of dielectric material

A technology for ceramic capacitors and dielectric materials, applied in the field of X7R type ceramic capacitor dielectric materials and their preparation, can solve the problems of lead, human body and environmental hazards, and achieve the effects of low cost, good temperature stability and good industrialization prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

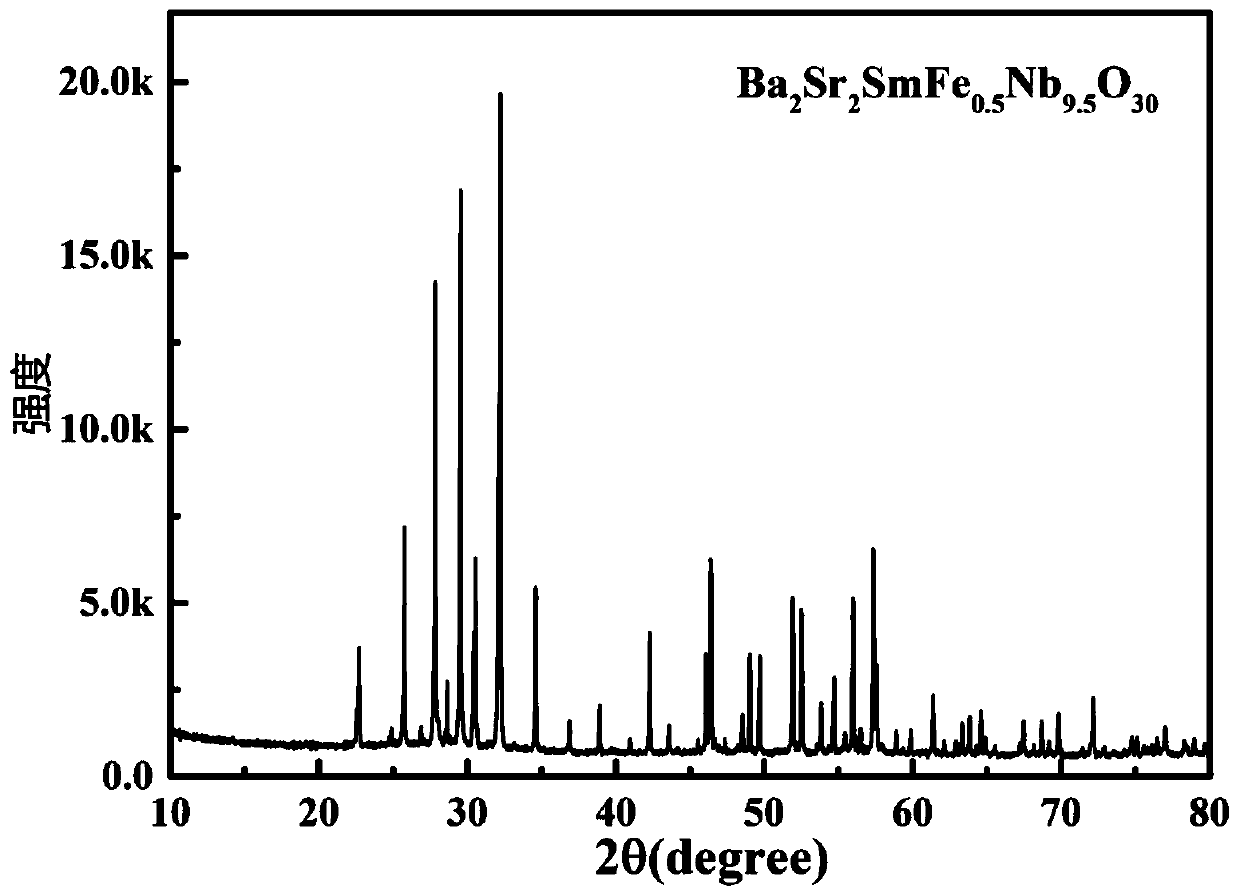

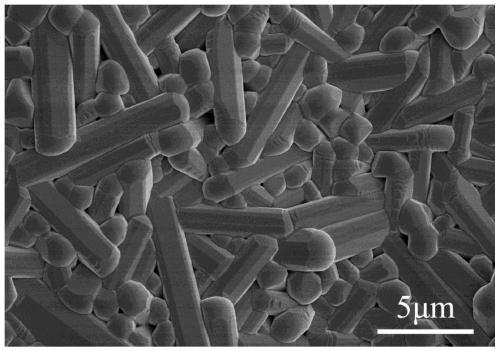

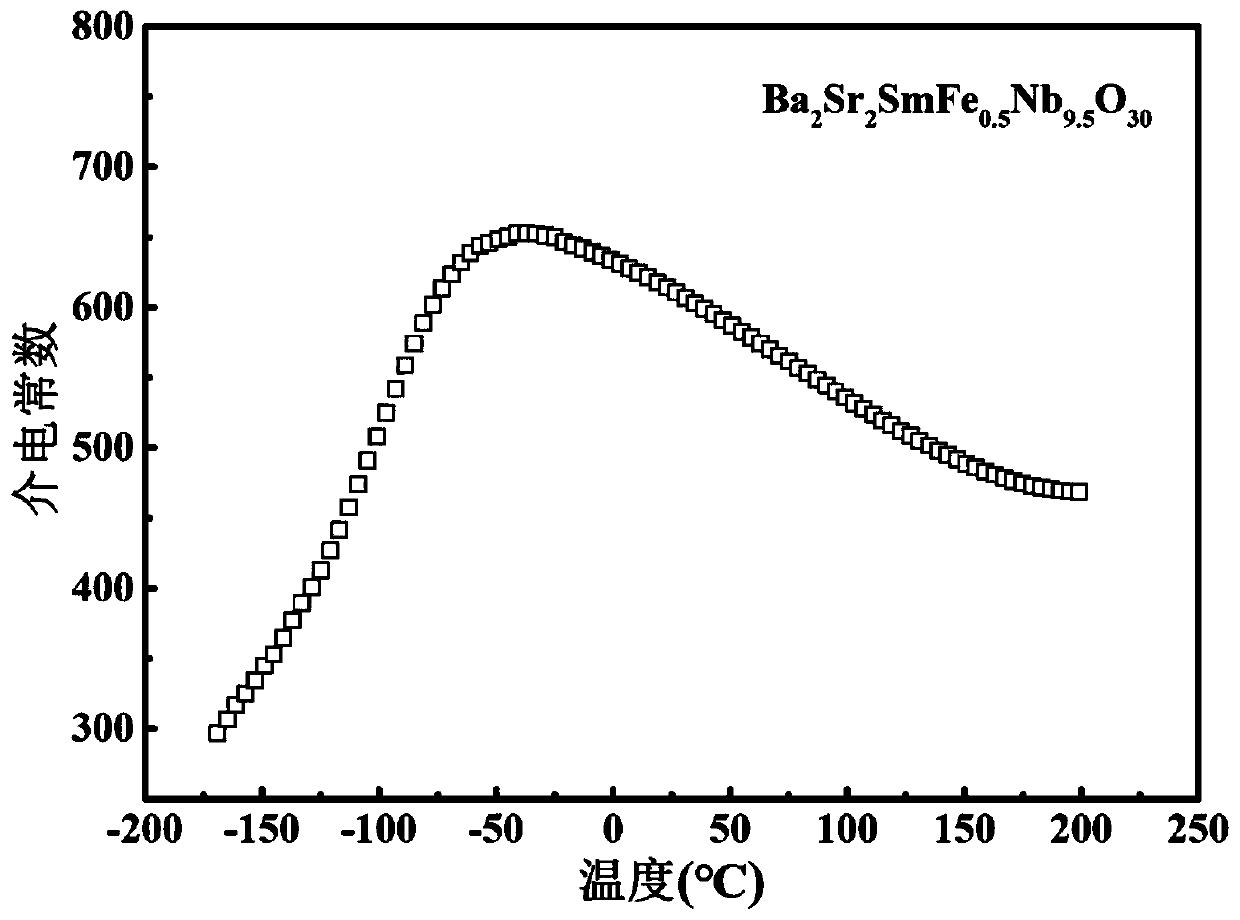

Embodiment 1

[0015] BaCO with a purity of 99.99% 3 , SrCO 3 、Sm 2 o 3 , Fe 2 o 3 and Nb 2 o 5 The raw material is Ba according to the stoichiometric ratio 2 Sr 2 SmFe 0.5 Nb 9.5 o 30 Put the ingredients into the ball mill tank; select zirconia balls and nylon tanks; the quality of the added raw materials is 8% of the mass of the balls; the mixing ball milling time is 24 hours, the speed is 350 rpm, and the ball milling medium is absolute ethanol; the obtained product Dry in an oven at 100°C for 4 hours, then pre-sinter at 1000°C for 4 hours at a heating rate of 5°C / min; take out the pre-fired powder and grind it, and then use absolute ethanol as the ball milling medium for 24 hours. Mix evenly, dry at 100°C for 4 hours, grind into powder, use 8% polyvinyl alcohol aqueous solution as a binder to granulate, pass through a 60-mesh sieve, and press under a pressure of 100MPa to form a particle with a diameter of 10mm, 1mm thickness disc-shaped green body, heat up to 400°C at a heat...

Embodiment 2

[0017] BaCO with a purity of 99.99% 3 , SrCO 3 、Sm 2 o 3 , Fe 2 o 3 and Nb 2 o 5 The raw material is Ba according to the stoichiometric ratio 2 Sr 2 SmFe 0.5 Nb 9.5 o 30 Put the ingredients into the ball mill tank; select zirconia balls and nylon tanks; the quality of the added raw materials is 8% of the mass of the balls; the mixing ball milling time is 24 hours, the speed is 350 rpm, and the ball milling medium is absolute ethanol; the obtained product Dry in an oven at 100°C for 4 hours, and pre-sinter at 1100°C at a rate of 5°C / min for 4 hours; take out the pre-fired powder and grind it, and then use absolute ethanol as the ball milling medium for 24 hours. Mix evenly, dry at 100°C for 4 hours, grind into powder, use 8% polyvinyl alcohol aqueous solution as a binder to granulate, pass through a 60-mesh sieve, and press under a pressure of 100MPa to form a particle with a diameter of 10mm, thickness of 1mm disc-shaped green body, the temperature rises to 550°C a...

Embodiment 3

[0019] BaCO with a purity of 99.99% 3 , SrCO 3 、Sm 2 o 3 , Fe 2 o 3 and Nb 2 o 5 The raw material is Ba according to the stoichiometric ratio 2 Sr 2 SmFe 0.5 Nb 9.5 o 30 Put the ingredients into the ball mill tank; select zirconia balls and nylon tanks; the quality of the added raw materials is 8% of the mass of the balls; the mixing ball milling time is 24 hours, the speed is 350 rpm, and the ball milling medium is absolute ethanol; the obtained product Dry in an oven at 100°C for 4 hours, then pre-sinter at 1150°C with a heating rate of 5°C / min for 4 hours; take out the pre-fired powder and grind it, and then use absolute ethanol as the ball milling medium for 24 hours. Mix evenly, dry at 100°C for 4 hours, grind into powder, use 8% polyvinyl alcohol aqueous solution as a binder to granulate, pass through a 60-mesh sieve, and press under a pressure of 100MPa to form a particle with a diameter of 10mm, thickness of 1mm disc-shaped green body, the temperature rises...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap