Method for preparing hydrophilic dry-mixed colorant applied to entire-body large-size ceramic sheet material

A ceramic pigment and large-scale technology, which is applied in the field of ceramic tile manufacturing, can solve the problems of narrowing differences, etc., and achieve the effects of easy acquisition, improved competitiveness, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

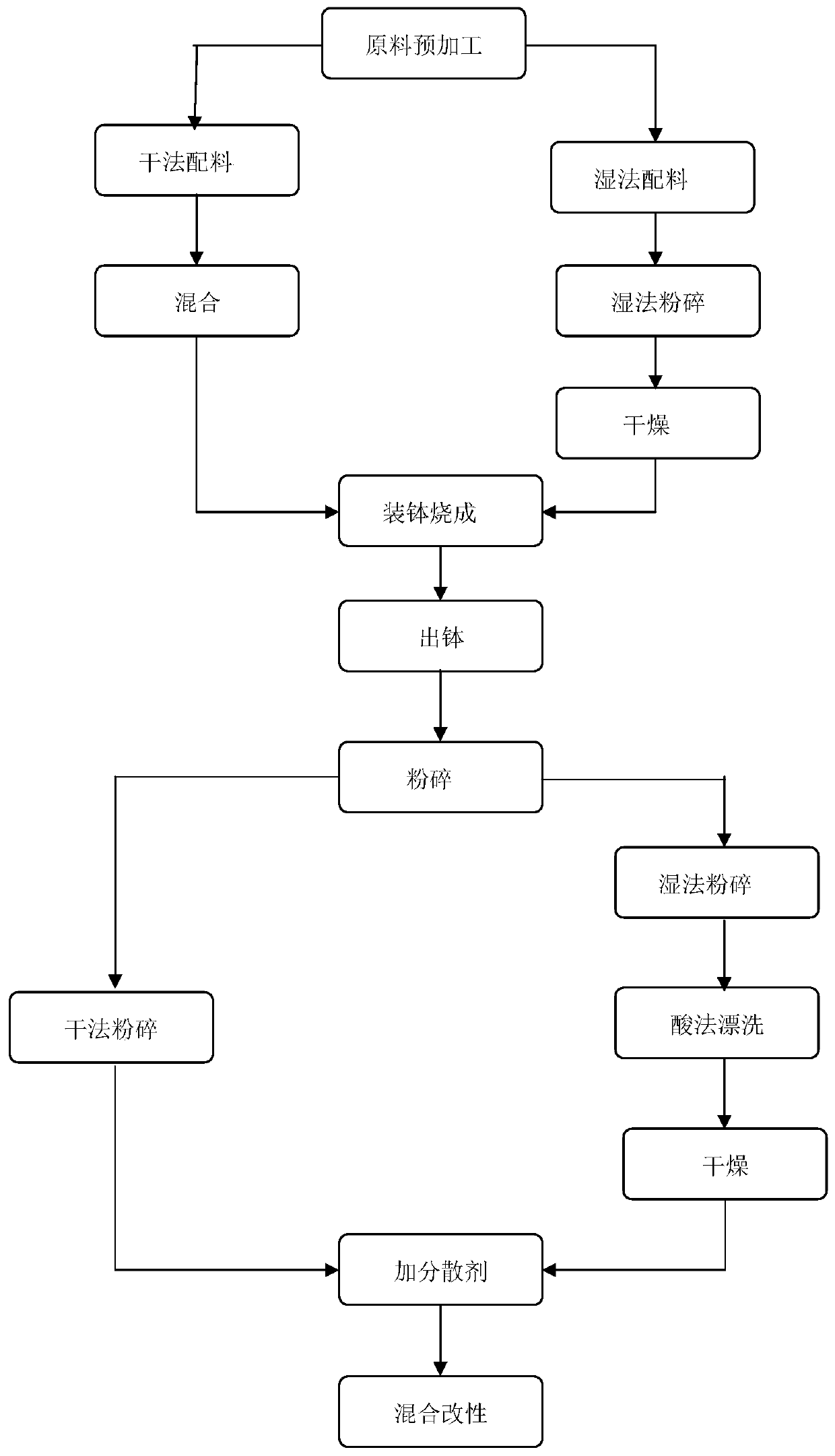

[0046]The preparation method of the hydrophilic dry-mix colorant applied to the large-scale ceramic plate of the whole body includes:

[0047] This method is based on the preparation process of conventional body color products, by controlling the water content and grinding the powder to a qualified fineness, adding 1-3% selected dispersant, and then using jet mill, ball mill or three-dimensional mixing mixer to stir can be obtained evenly.

[0048] The dispersant is selected from one or more mixtures of microcrystalline cellulose, sodium aluminosilicate, water-soluble anti-caking agent, micropowder silica gel, and its formula is:

[0049] Water-soluble anti-caking agent A 40% Water-soluble anti-caking agent B 40% Water-soluble anti-caking agent C 10%

[0050] Microcrystalline Cellulose 5%. Sodium aluminosilicate 2.5% Micropowder silica gel 2.5%

[0051] The main component of the microcrystalline cellulose is linear polysaccharides bound by β-1,4-glucosidic bonds, and the de...

Embodiment example 2

[0055] The preparation method of the hydrophilic dry-mix colorant applied to the large-scale ceramic plate of the whole body: on the basis of the preparation process of the conventional green body colorant product, after controlling the water content and grinding the powder to a qualified fineness, add 1-3 % selected dispersant, and then use jet mill, ball mill or three-dimensional mixing mixer to stir evenly to get it.

[0056] The dispersant is selected from one or more mixtures of microcrystalline cellulose, sodium aluminosilicate, water-soluble anti-caking agent, micropowder silica gel, and its formula is:

[0057] Water-soluble anti-caking agent A 40% Water-soluble anti-caking agent B 20% Water-soluble anti-caking agent C 20%

[0058] Microcrystalline Cellulose 10% Sodium Aluminosilicate 5% Micronized Silica Gel 5%

[0059] The main component of the microcrystalline cellulose is linear polysaccharides bound by β-1,4-glucosidic bonds, and the degree of polymerization is a...

Embodiment example 3

[0063] The preparation method of the hydrophilic dry-mix colorant applied to the large-scale ceramic plate of the whole body: on the basis of the preparation process of the conventional green body colorant product, after controlling the water content and grinding the powder to a qualified fineness, add 1-3 % selected dispersant, and then use jet mill, ball mill or three-dimensional mixing mixer to stir evenly to get it.

[0064] The dispersant is selected from one or more mixtures of microcrystalline cellulose, sodium aluminosilicate, water-soluble anti-caking agent, micropowder silica gel, and its formula is:

[0065] Water-soluble anti-caking agent A 40% Water-soluble anti-caking agent B 20% Water-soluble anti-caking agent C 20%

[0066] Microcrystalline Cellulose 10% Sodium Aluminosilicate 5% Micronized Silica Gel 5%

[0067] The main component of the microcrystalline cellulose is linear polysaccharides bound by β-1,4-glucosidic bonds, and the degree of polymerization is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com