Titanium-based active bone implant and preparation method thereof

A bone implantation and active technology, applied in the direction of prosthesis, coating, tissue regeneration, etc., can solve problems such as limitations, and achieve the effect of promoting bone-related cell osteogenic differentiation and good ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

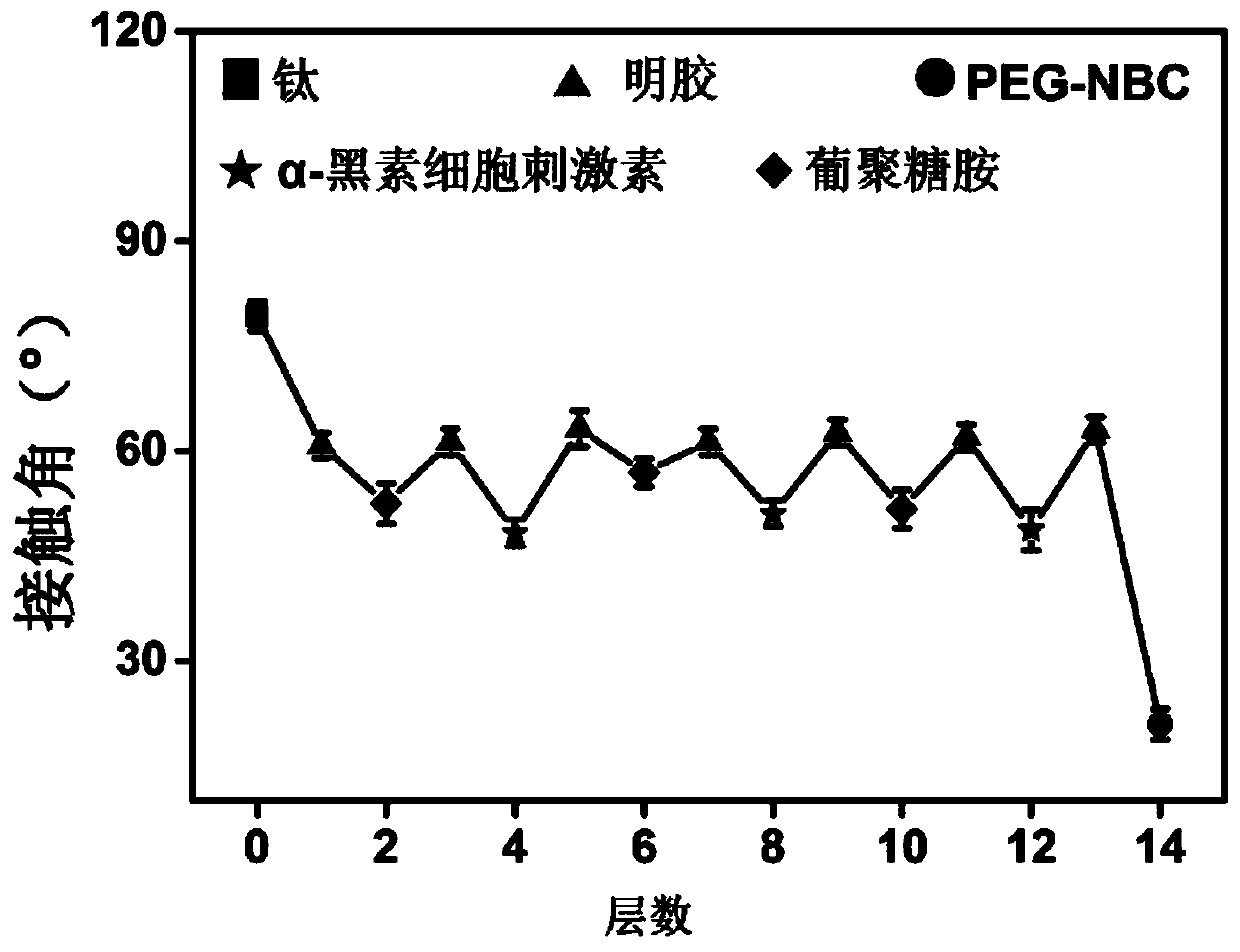

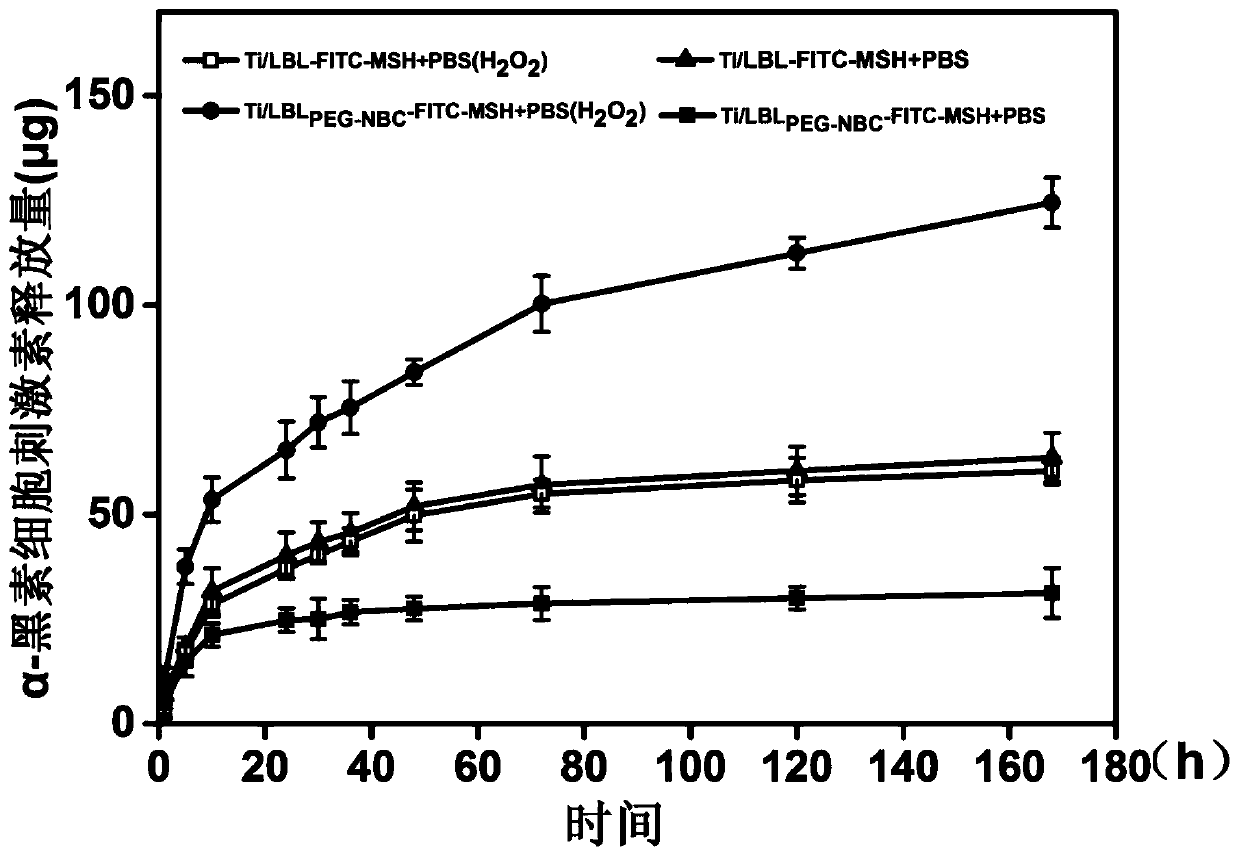

[0033] Preparation of titanium-based active bone implants

[0034] (1) Dissolve 0.47g of p-nitrobenzoic chloroformate in 15mL of tetrahydrofuran, and fill with nitrogen at 0°C to obtain solution I;

[0035] (2) 0.5g 4-(hydroxymethyl) phenylboronic acid pinacol ester, 0.04g 4-dimethylaminopyridine and 0.6mL triethylamine were dissolved in 5mL tetrahydrofuran to obtain solution II;

[0036] (3) Under ice bath conditions, add solution I in step (1) dropwise to solution II in step (2) through 10 min under stirring, then stir the reaction at room temperature at a speed of 600 r / min for 3 h, spin dry Afterwards, the spin-dried product was dissolved in dichloromethane to obtain a yellow solution, which was washed with 1M HCl and saturated NaCl solution successively, and then washed with NaHCO 3 The solution was washed until the color of the yellow solution turned light yellow, and finally passed through a silica gel column, followed by a mixture of petroleum ether and dichloromethan...

Embodiment 2

[0042] Preparation of titanium-based active bone implants

[0043] (1) Dissolve 0.47g of p-nitrobenzoic chloroformate in 15mL of tetrahydrofuran, and fill with nitrogen at 0°C to obtain solution I;

[0044] (2) 0.5g 4-(hydroxymethyl) phenylboronic acid pinacol ester, 0.04g 4-dimethylaminopyridine and 0.6mL triethylamine were dissolved in 5mL tetrahydrofuran to obtain solution II;

[0045] (3) Under ice bath conditions, add solution I in step (1) dropwise to solution II in step (2) through 20min under stirring, then stir the reaction at room temperature at a speed of 300r / min for 4h, spin dry Afterwards, the spin-dried product was dissolved in dichloromethane to obtain a yellow solution, which was washed with 1M HCl and saturated NaCl solution successively, and then washed with NaHCO 3 The solution was washed until the color of the yellow solution turned light yellow, and finally passed through a silica gel column, followed by a mixture of petroleum ether and dichloromethane i...

Embodiment 3

[0050] Preparation of titanium-based active bone implants

[0051] (1) Dissolve 0.47g of p-nitrobenzoic chloroformate in 15mL of tetrahydrofuran, and fill with nitrogen at 0°C to obtain solution I;

[0052] (2) 0.5g 4-(hydroxymethyl) phenylboronic acid pinacol ester, 0.04g 4-dimethylaminopyridine and 0.6mL triethylamine were dissolved in 5mL tetrahydrofuran to obtain solution II;

[0053] (3) Under ice bath conditions, add solution I in step (1) dropwise to solution II in step (2) through 15min under stirring, then stir the reaction at room temperature at a speed of 800r / min for 3h, spin dry Afterwards, the spin-dried product was dissolved in dichloromethane to obtain a yellow solution, which was washed with 1M HCl and saturated NaCl solution successively, and then washed with NaHCO 3 The solution was washed until the color of the yellow solution turned light yellow, and finally passed through a silica gel column, followed by a mixture of petroleum ether and dichloromethane i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com