A kind of method of synthesizing furan compound

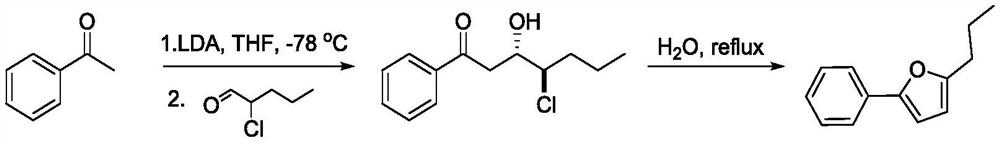

A compound and furan technology, applied in the field of organic compound synthesis, can solve the problems of 2-chloro-n-valeraldehyde, which is a raw material that is not readily available, dangerous use of diisopropylamide lithium, and complicated reaction processes, and achieves substrate adaptability. Good, easy to obtain raw materials, simple reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

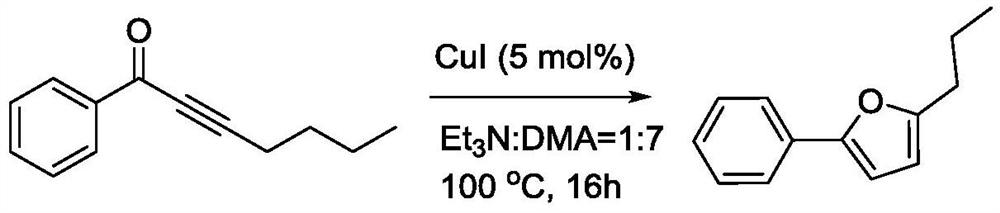

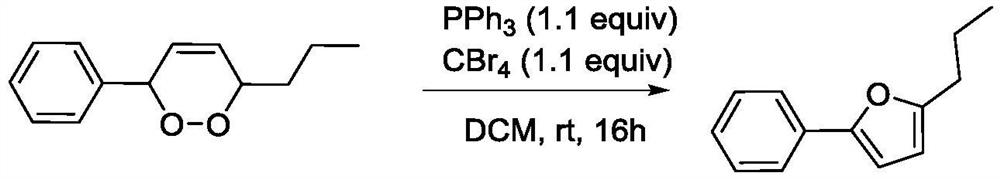

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation process of gold catalyst described in the embodiment is:

[0036] Synthesis of A: Add 5-bromoisoquinoline (10mmol), 2-bromophenylboronic acid (1.06equiv.), tetrakis(triphenylphosphine) palladium (5mol%), carbonic acid Sodium hydrogen (4.5 equiv.), and under nitrogen protection, add 20ml of ethylene glycol dimethyl ether and 10ml of deionized water into the bottle with a syringe, and heat the system to 95°C to react overnight. After the reaction, cool to room temperature, extract with dichloromethane, collect the organic phase, and extract the water phase twice, combine the organic phase, wash the organic phase with water, and dry with anhydrous sodium sulfate, then use column chromatography Product A was isolated.

[0037] Synthesis of B: Add A (10 mmol) and 30 ml tetrahydrofuran into a round-bottomed flask equipped with a magnet, add methyl iodide (1.5 equiv.) under stirring at room temperature, and react for 24 hours. After the reaction, a large numb...

Embodiment 1

[0044]

[0045] 0.004mmol Add 0.02mmol tetrakis(3,5-bis(trifluoromethyl)phenyl)sodium borate into a 15ml Schlenck tube, after the nitrogen protection is completed, add 0.2mmol 1-phenylhept-2-yn-1-one with a syringe and 2mL DCE. Then, react at 60 degrees Celsius for 2 hours. After the reaction, add two tablespoons of column chromatography silica gel (100-200 mesh) to the reaction solution, and remove the solvent by distillation under reduced pressure, and then separate the pure product by column chromatography (using petroleum ether as eluent). The material was a yellow liquid in 96% yield.

[0046] Characterization data: 1 H NMR (500MHz, CDCl 3 )δ7.69(dd,J=8.4,1.1Hz,2H), 7.41–7.38(m,2H),7..27–7.24(m,1H),6.60(d,J=3.2Hz,1H), 6.11(d, J=3.2Hz, 1H), 2.71(t, J=7.4Hz, 2H), 1.81-1.73(m, 2H), 1.05(t, J=7.4Hz, 3H). 13 C NMR (125MHz, CDCl 3 )δ156.28, 152.18, 131.33, 128.58, 126.71, 123.35, 106.98, 105.64, 30.22, 21.47, 13.76.

Embodiment 2

[0048]

[0049] 0.01mmol Add 0.02mmol tetrakis(3,5-bis(trifluoromethyl)phenyl)sodium borate into a 15ml Schlenck tube, after the nitrogen protection is completed, add 0.2mmol 1-(3-bromophenyl)hept-2- Alkyn-1-one and 2 mL DCE. Next, react at 60 degrees Celsius for 2 hours. After the reaction, add two tablespoons of column chromatography silica gel (100-200 mesh) to the reaction solution, and remove the solvent by distillation under reduced pressure, and then separate the pure product by column chromatography (using petroleum ether as eluent). The material was a yellow liquid and the yield was 93%.

[0050] Characterization data: 1 H NMR (500MHz, CDCl 3 )δ7.82(dd,J=7.9,1.7Hz,1H), 7.65(dd,J=8.0,1.1Hz,1H),7.39–7.32(m,1H),7.13(d,J=3.3Hz, 1H ),7.12–7.07(m,1H),6.16(d,J=3.3Hz,1H),2.70(t,J=7.5Hz, 2H),1.84–1.70(m,2H),1.04(t,J= 7.4Hz, 3H). 13 C NMR (125MHz, CDCl 3 )δ156.48, 149.45, 134.09, 131.55, 128.32, 127.74, 127.28, 119.16, 111.48, 106.93, 30.15, 21.42, 13.78.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com