7-ketone lithocholic acid intermediate, preparation method and applications thereof

An intermediate and cornerstone technology, applied in the field of 7-ketolithocholic acid intermediate and its preparation, can solve the problems of waste of resources, environment, separation difficulties, pollution, etc., and achieve mild and not harsh reaction conditions, simple process flow, and safety factor high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

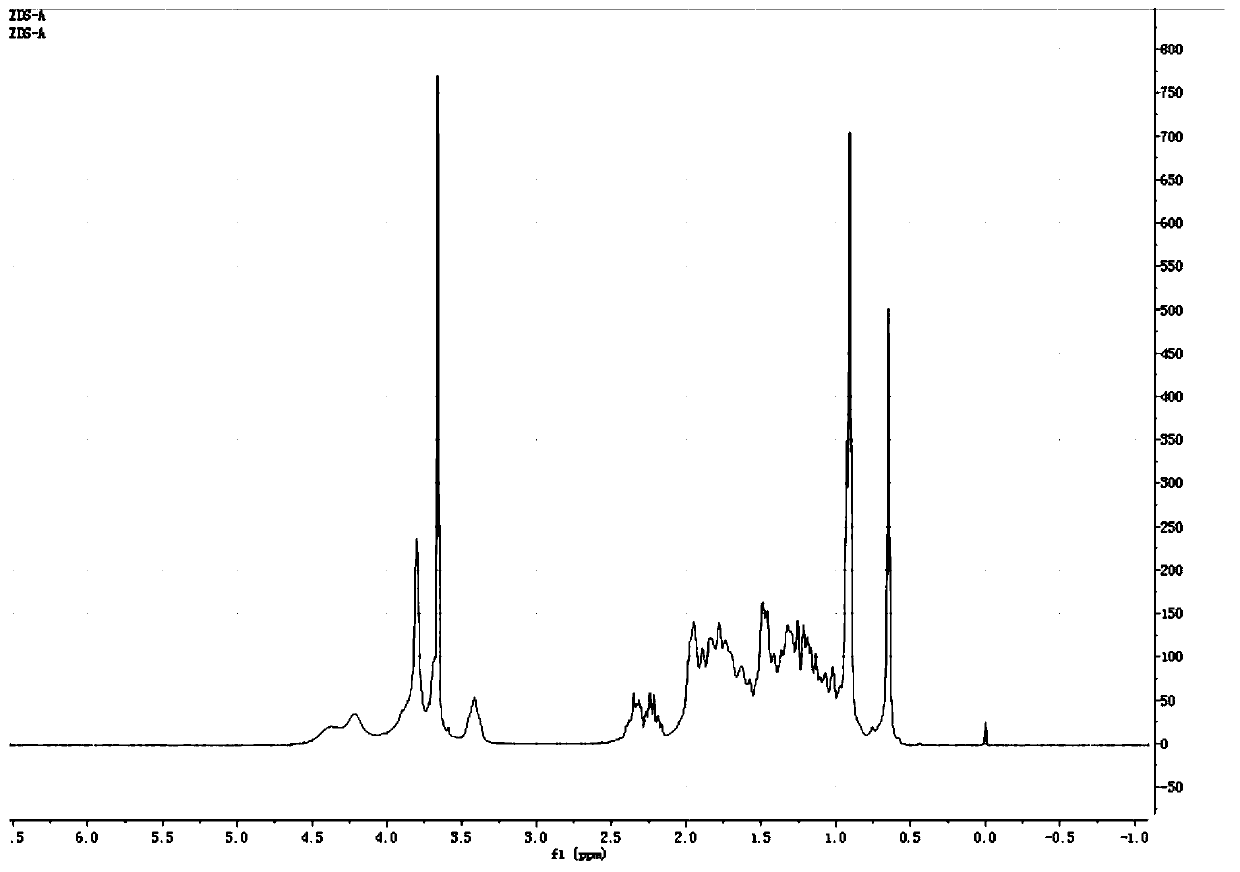

Image

Examples

Embodiment 1

[0067] In this example, R 1 is methyl, R 2 is acetyl, R 3 For methanesulfonyl.

[0068] The preparation method of 7-keto lithocholic acid intermediate comprises the following steps:

[0069] Step 1: Dissolve 5kg of hyocholic acid in 50kg of methanol, add 300g of sulfuric acid, heat up to reflux and stir for 3 hours, TLC monitors that the reaction is complete, stop the reaction, concentrate to remove the solvent, a large amount of solids are precipitated, filter to obtain intermediate 1, and vacuum-dry Obtain 5kg of white solid;

[0070] Step 2: Dissolve 2kg of intermediate 1 in 20kg of acetone, add 100g of sulfuric acid and 3kg of 2,2-dimethoxypropane, heat up to reflux and stir for 2 hours, TLC monitors the reaction is complete, stop the reaction, concentrate to remove the solvent, a large amount of solid Precipitation, filtration to obtain intermediate 2, 2.1 kg of white solid dried in vacuum at 50°C;

[0071] Step 3: Dissolve 1 kg of intermediate 2 in 10 kg of acetic a...

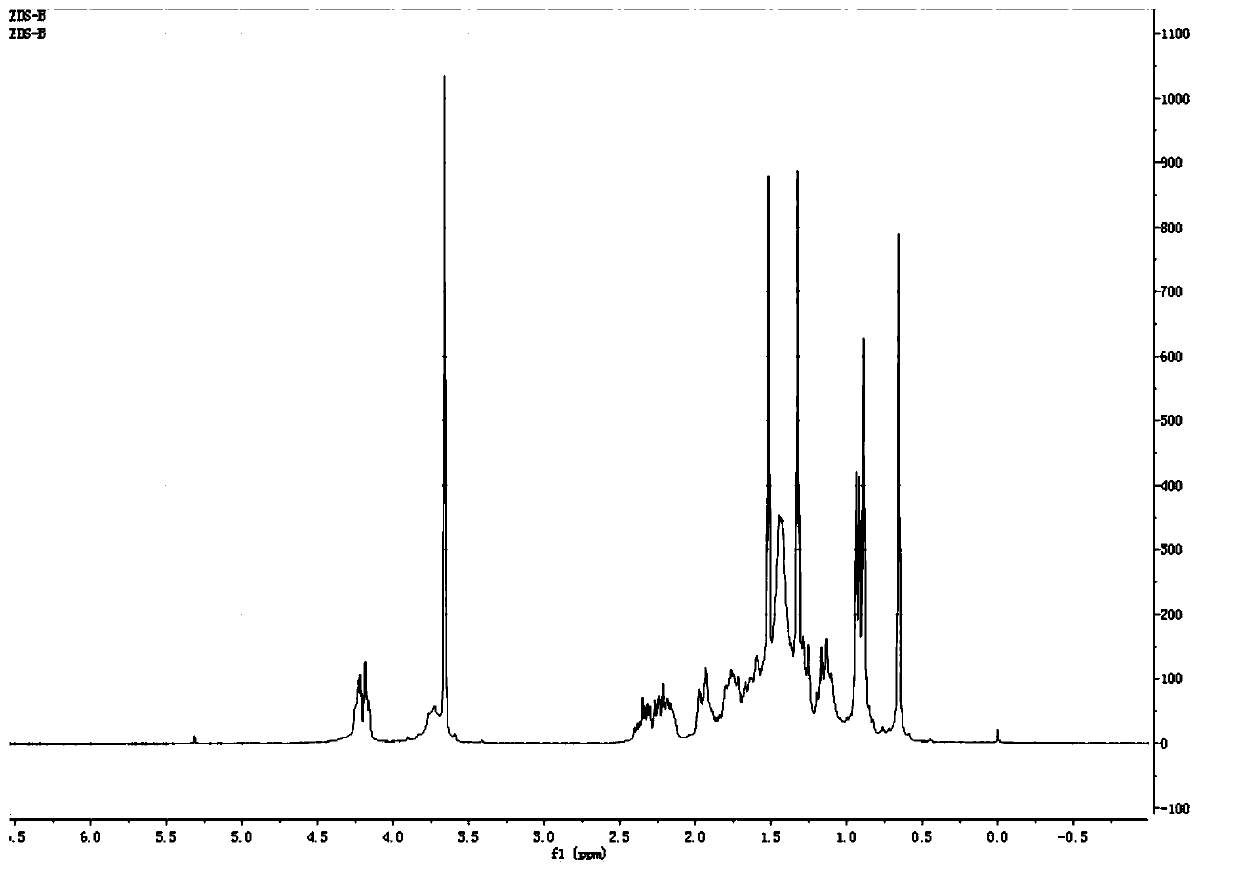

Embodiment 2

[0079] In this example, R 1 is methyl, R 2 is acetyl, R 3 For methanesulfonyl.

[0080] The preparation method of 7-keto lithocholic acid intermediate comprises the following steps:

[0081] Step 1: Dissolve 5kg of hyocholic acid in 50kg of methanol, add 300g of sulfuric acid, heat up to reflux and stir for 3 hours, TLC monitors that the reaction is complete, stop the reaction, concentrate to remove the solvent, a large amount of solids are precipitated, filter to obtain intermediate 1, and vacuum-dry Obtain 5kg of white solid;

[0082] Step 2: Dissolve 2kg of intermediate 1 in 20kg of toluene, add 100g of methanesulfonic acid and 3kg of 2,2-dimethoxypropane, heat up to reflux and stir for 2 hours, TLC monitors the reaction is complete, stop the reaction, concentrate to remove the solvent, A large amount of solids were precipitated, and Intermediate 2 was obtained by filtration, and 2.1 kg of white solids were dried under vacuum at 50°C;

[0083] Step 3: Dissolve 1 kg of ...

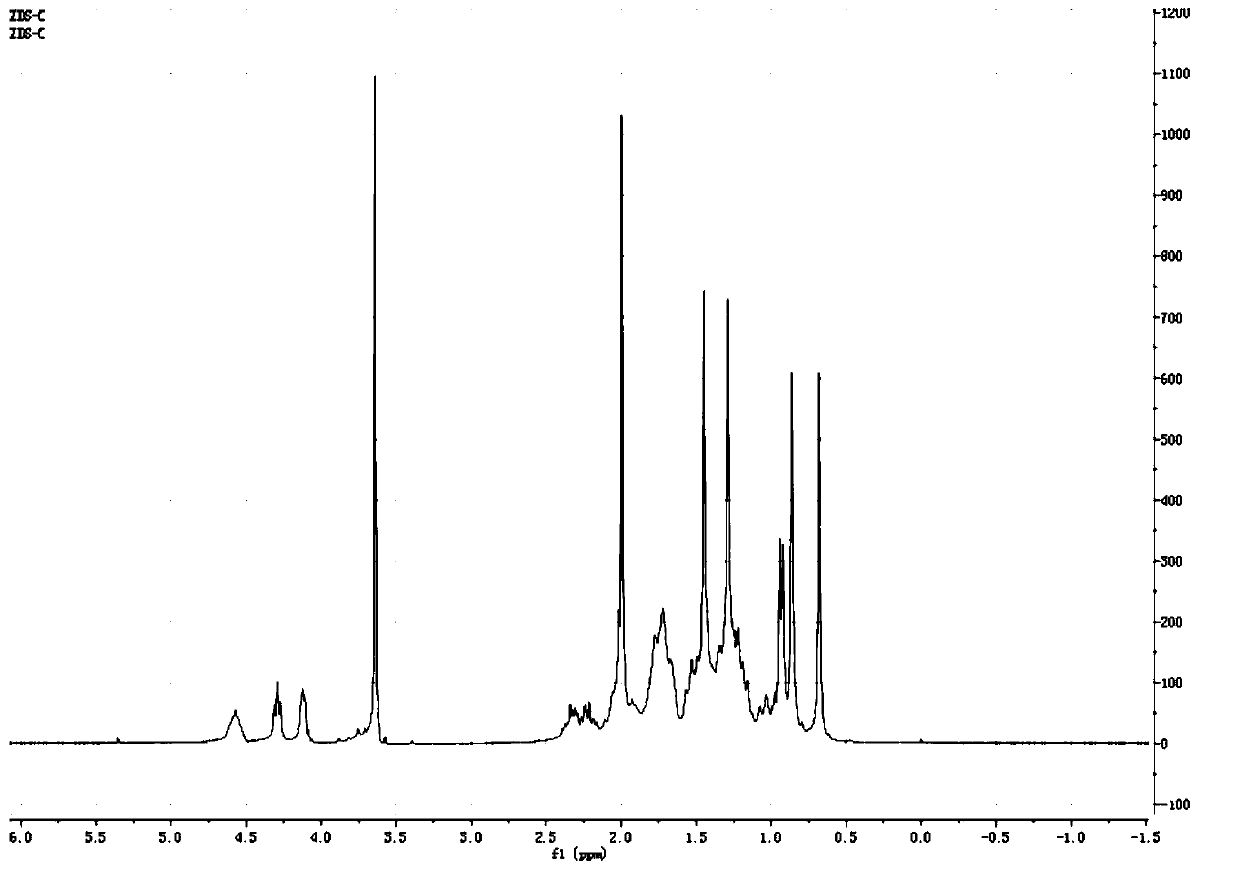

Embodiment 3

[0091]This embodiment is based on embodiment 1 or embodiment 2, and the difference with embodiment 1 or embodiment 2 is:

[0092] The second step: the preparation of intermediate 7:

[0093] Dissolve 10g of intermediate 6 in 200g of methyl isobutyl ketone, add 36.4g of lithium iodide, 16g of fully activated zinc powder and 10g of deionized water, reflux and stir for 72 hours, stop the reaction, TLC monitors that the reaction is complete, stop For the reaction, the reaction liquid was dropped into 400 g of deionized water, a large amount of solids were precipitated, and the intermediate 7 was obtained by filtration, and vacuum-dried at 50° C. to obtain 6.8 g of white solids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com