A kind of polyimide airgel with lotus leaf effect and its preparation method and application

A technology of polyimide gel and polyimide, which is applied in the field of nanoporous materials and heat insulation, can solve the problems of low output, high porosity, low thermal conductivity, etc., and achieve huge application prospects and large specific surface area , the effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Another aspect of the embodiments of the present invention also provides a method for preparing the aforementioned polyimide airgel with lotus leaf effect, which includes:

[0043]Mixing the first polyamic acid solution and the second polyamic acid solution uniformly to form a mixed system;

[0044] A chemical dehydrating agent is added to the mixed system, and then the polyimide gel is formed by standing still, and then aged, solvent replaced and dried to obtain the polyimide airgel with lotus leaf effect.

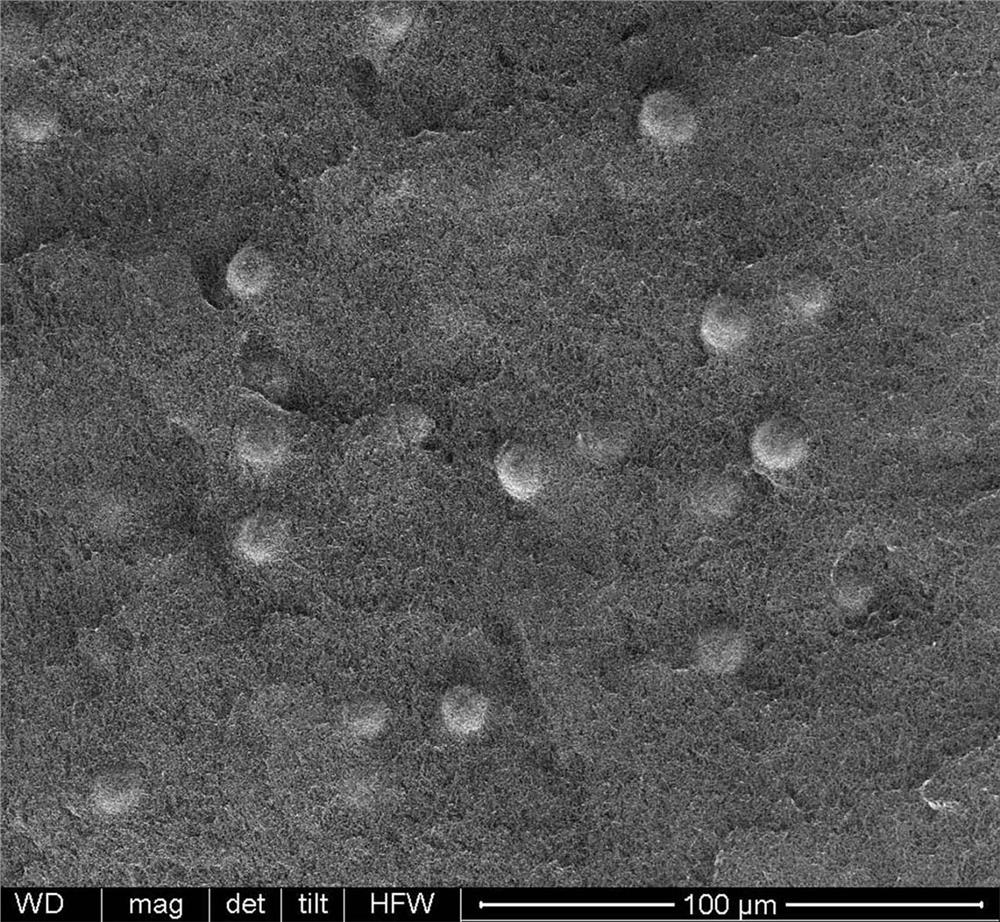

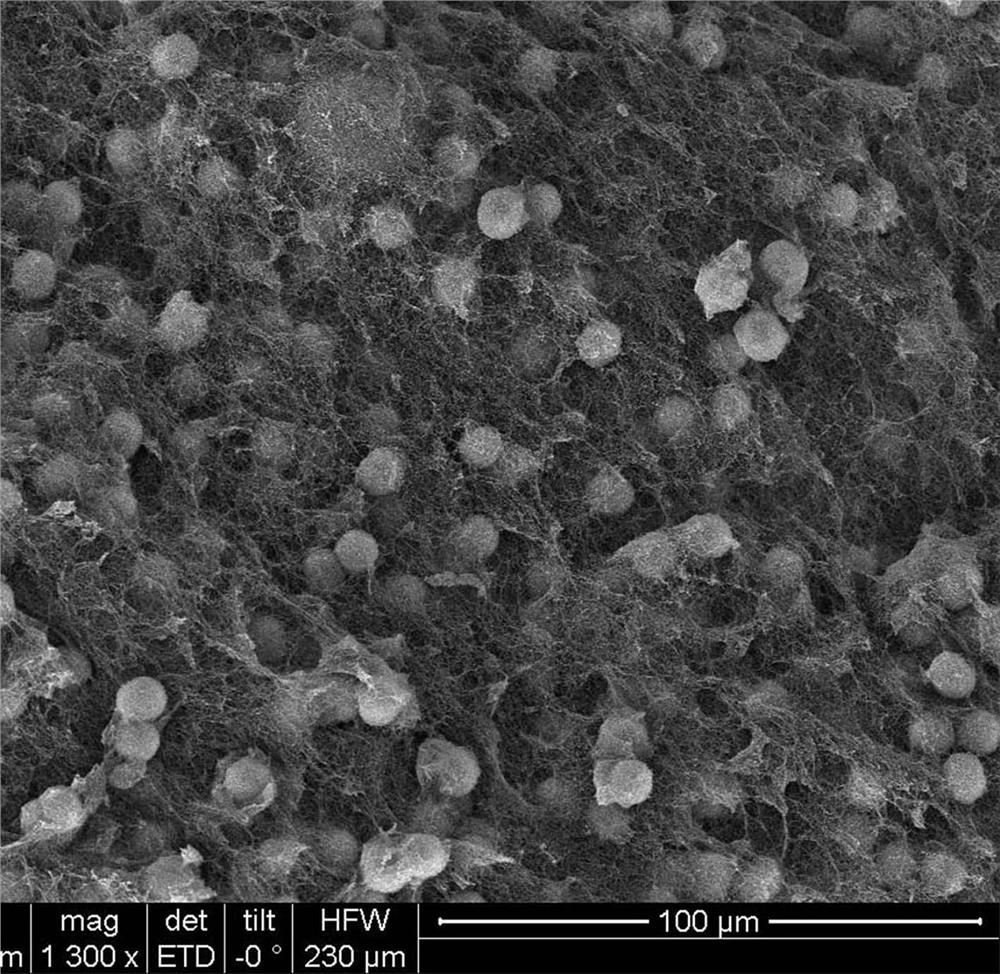

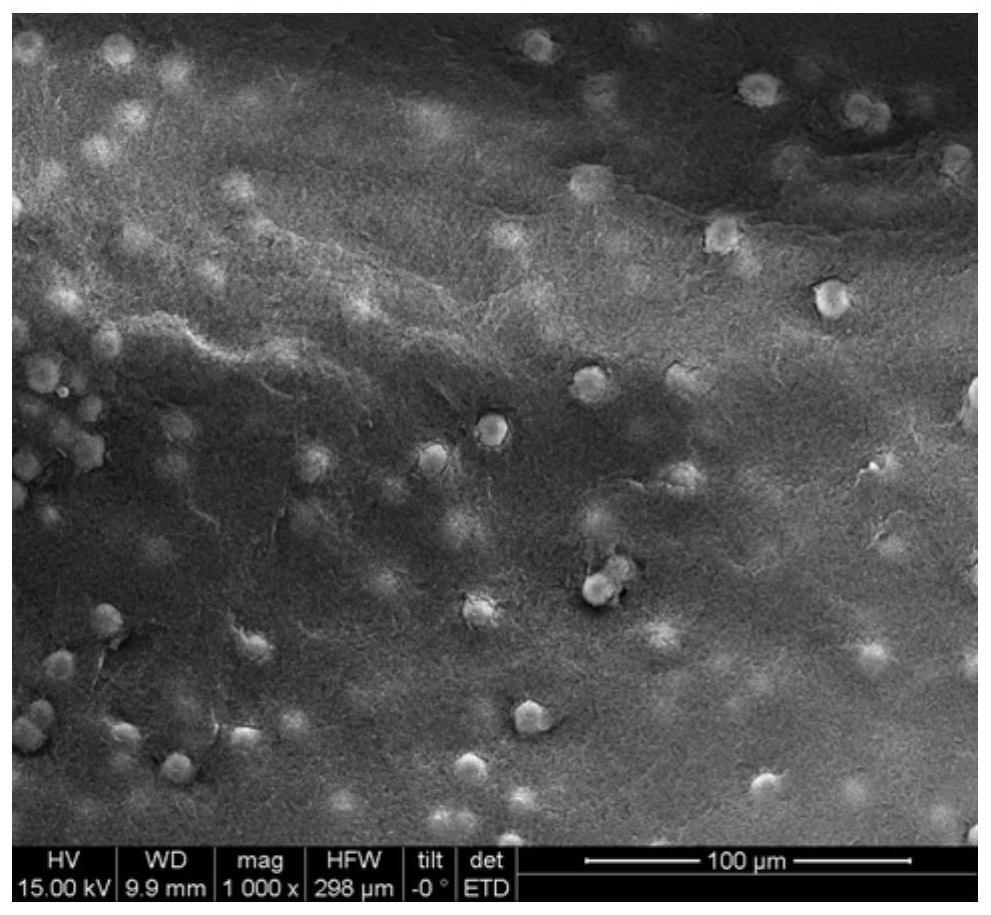

[0045] Further, the formation of the island structure in the polyimide airgel of the present invention depends on the reaction steps and the type of the first polyamic acid solution. Based on this, the island structure and the lotus leaf effect of the present invention can be obtained.

[0046] Preferably, the first polyamic acid is different from the second polyamic acid.

[0047] In some embodiments, the first polyamic acid solution includes the first polyamic ...

Embodiment 1

[0077] (1) Synthesis and compounding of polyamic acid: p-phenylenediamine and bisphenol A dianhydride condensed polyamic acid (mass concentration is 1%) in 1g N-methylpyrrolidone in synthetic repeating unit number; In N-methylpyrrolidone, the polyamic acid (mass concentration is 5%) of 4,4'-diaminodiphenyl ether and 4,4'-biphenyl ether dianhydride (mass concentration is 5%) with 100 repeating units; the above two The polyamic acid was mixed thoroughly, stirred for 10 minutes, and ultrasonicated for 5 minutes.

[0078] (2) Synthesis of polyimide gel: Add 25g of acetic anhydride / triethylamine (molar ratio: 1:1) mixture to the above polyamic acid mixture, stir rapidly for 10 minutes, and ultrasonically deaerate for 30 minutes. minute. Finally, the obtained solution was left standing at 10° C., and a polyimide gel was formed after 5 hours.

[0079] (3) Preparation of polyimide airgel with lotus leaf effect: put the above polyimide gel at 80°C for aging for 24 hours, then soak it...

Embodiment 2

[0081] (1) Synthesis and compounding of polyamic acid: p-phenylenediamine and bisphenol A dianhydride condensed polyamic acid (mass concentration is 5%) in 20g N-methylpyrrolidone in synthetic repeat unit number; The polyamic acid (mass concentration is 30%) of 9,9-bis(4-aminophenyl)fluorene and 4,4'-biphenyl ether dianhydride synthesized in N-methylpyrrolidone with 10 repeating units; The above two polyamic acids are fully mixed, stirred for 15 minutes, and ultrasonicated for 10 minutes.

[0082] (2) Synthesis of polyimide gel: 50 g of acetic anhydride / pyridine (1:1 molar ratio) mixture was added to the above polyamic acid mixture, stirred rapidly for 20 minutes, and ultrasonically degassed for 20 minutes. Finally, the obtained solution was left standing at 30° C., and a polyimide gel was formed after 3 hours.

[0083] (3) Preparation of polyimide airgel with lotus leaf effect: put the above polyimide gel at 60°C for aging for 24 hours, then soak it in 150g N-methylpyrrolido...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com