Preparation method and application of biological carbon-based iron carrying composite material

A composite material, biochar technology, applied in chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve problems such as difficulty in recycling, and achieve the effects of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

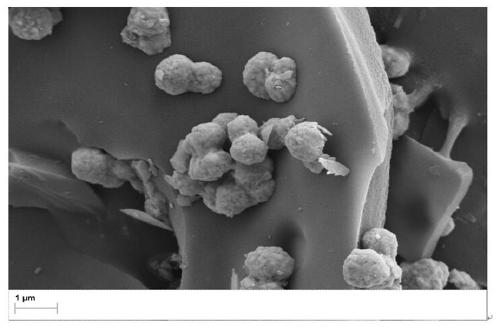

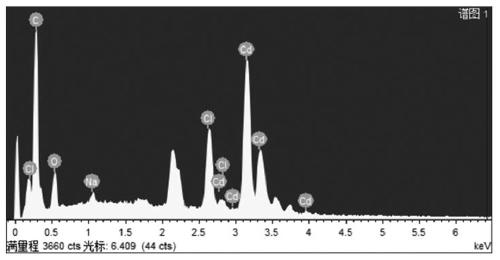

Image

Examples

Embodiment 1

[0024] (1) Transplant pokeweed with a plant height of 10cm-20cm, and the pot culture soil is vermiculite. Spray Hoagland nutrient solution at the initial stage of cultivation, spray 2 times a day, once every 12 hours, spray 20mL-100mL Hoagland nutrient solution each time, continuously Spray for 10 days;

[0025] (2) Apply FeSO-containing 4 and Fe 2 (SO 4 ) 3 The nutrient solution mixed with iron salts, the Fe concentration is 400mg / L; spray 3 times a day, with an interval of 8 hours between each time, and spray continuously for 40 days;

[0026] (3) Collect Phytolacca plants, dry them at room temperature, and store them as biomass raw materials;

[0027](4) Use the microwave digestion method to determine the Fe content of pokeweed biomass raw materials as shown in Table 1.

[0028] Table 1 Fe content of pokeweed biomass

[0029] sample Fe (mg / g) pokeweed stem 1.675±0.154 Phytolacca 2.356±0.173 Shanglugen 1.965±0.185

Embodiment 2

[0031] (1) Take the dried FeSO 4 For the irrigated pokeweed leaf biomass, add an appropriate amount of deionized water to cover the leaves, put it into a high-pressure reactor, add NaOH at a concentration of 10 mg / mL, and add hydrazine hydrate at a volume ratio of 1:10;

[0032] (2) Add magnetic beads of appropriate size to the inner tank of the autoclave, put the autoclave into a collector type constant temperature heating magnetic stirrer, set the temperature at 180°C, the speed at 50rmp, and the reaction time at 12h;

[0033] (3) After cooling to room temperature, take out the autoclave, vacuum filter the mixed solution in the liner, and separate the solid biochar-based iron-carrying composite material;

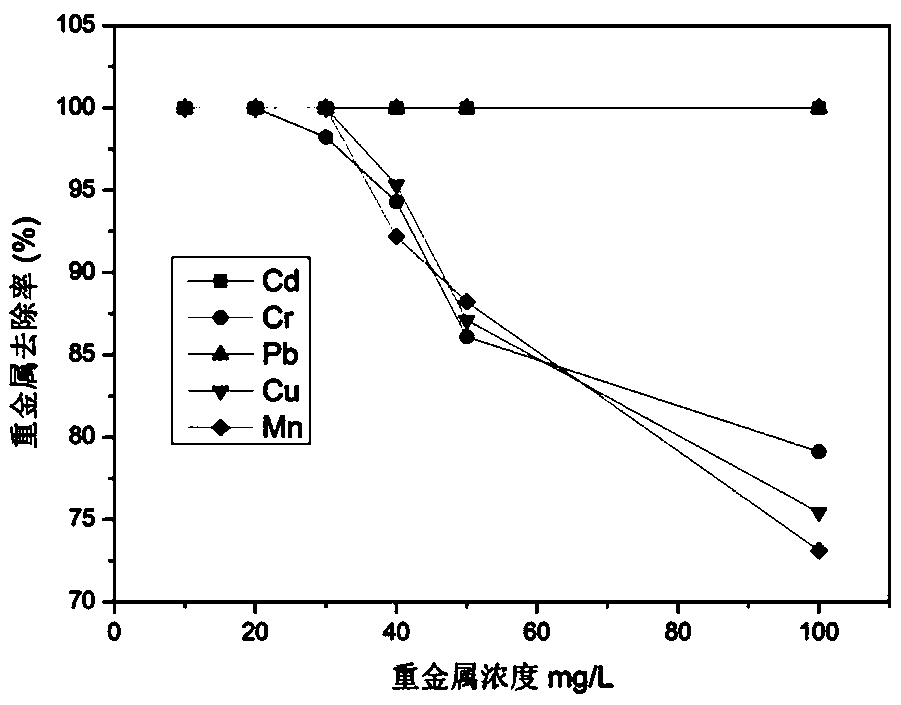

[0034] (4) Remove 500mg / L of Cd with 300mg / L of biochar-based iron-loaded composite material 2+ With 30mg / L Cr 6+ ;

[0035] (5) After 10 minutes of adsorption, Cd 2+ The removal rate is 85.3%, Cr 6+ The removal rate is 77.5%;

[0036] (6) For adsorbed Cd 2+ The bio...

Embodiment 3

[0038] (1) Take the dried FeCl 3 For the irrigated pokeweed leaf biomass, add an appropriate amount of deionized water to cover the leaves, put it into a high-pressure reactor, add NaOH at a concentration of 10 mg / mL, and add hydrazine hydrate at a volume ratio of 1:20;

[0039] (2) Add magnetic beads of appropriate size to the inner tank of the autoclave, put the autoclave into a collector type constant temperature heating magnetic stirrer, set the temperature at 200°C, the speed at 100rmp, and the reaction time at 12h;

[0040] (3) After cooling to room temperature, take out the autoclave, vacuum filter the mixed solution in the liner, and separate the solid biochar-based iron-carrying composite material;

[0041] (4) Remove 500mg / L of Cd with 500mg / L of biochar-based iron-loaded composite material 2+ With 40mg / L Cr 6+ ;

[0042] (5) After 30 minutes of adsorption, Cd 2+ The removal rate is 98.7%, Cr 6+ The removal rate was 95.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com