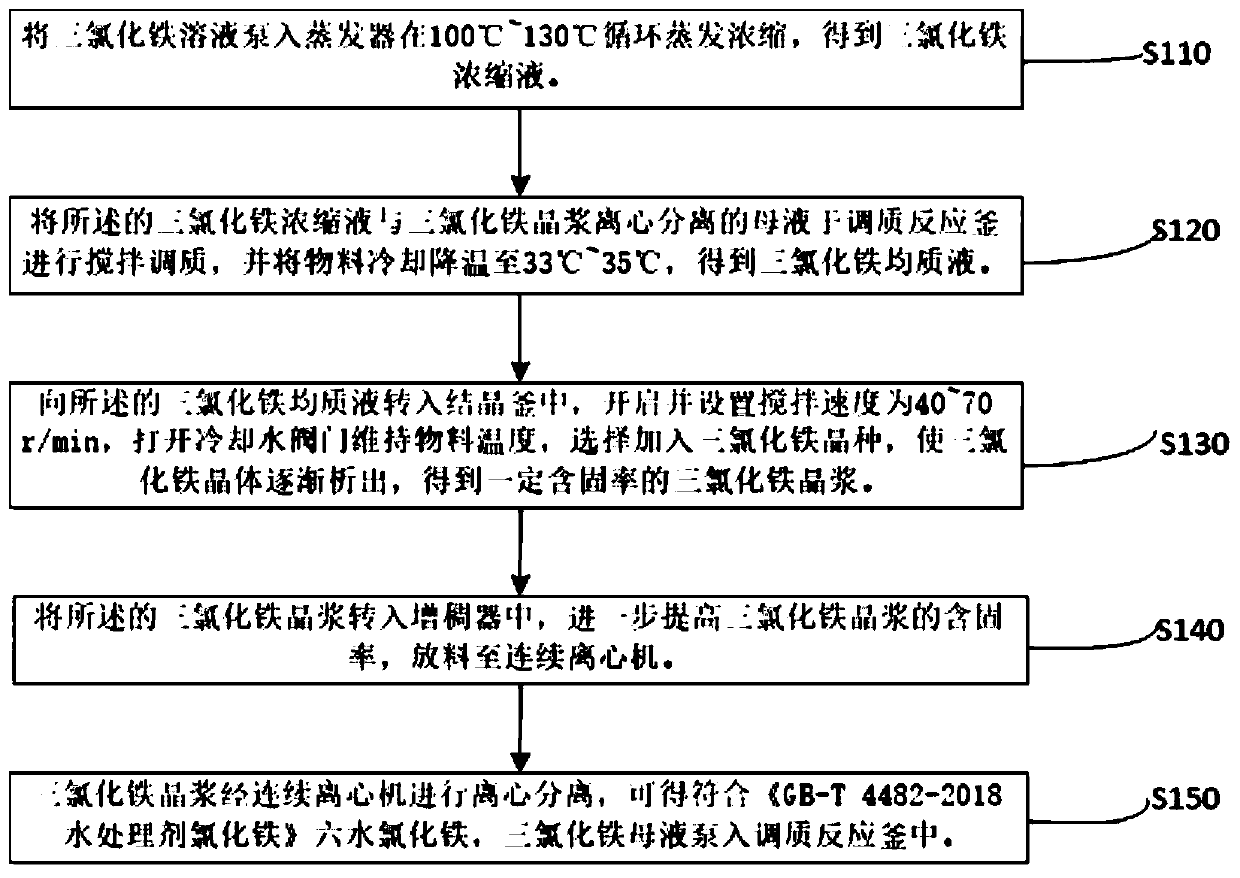

Method for continuous production of ferric chloride

A technology of ferric chloride and ferric chloride crystal, which is applied in the fields of ferric halide, chemical industry, climate sustainability, etc., can solve the problems of long crystallization process time, time-consuming feeding and discharging, low production efficiency, etc., to avoid Abnormal shaking phenomenon, shortening crystallization time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Pump the ferric chloride solution into the evaporator to circulate and evaporate and concentrate at 100°C to 130°C to obtain concentrated ferric chloride (Fe 3+ : 20.0%, Fe 2+ : 0.05%, HCl: 0.38%). The mother liquor (Fe 3+ : 21.02%, Fe 2+ : 0.02%, HCl: 0.31%) stirred in the tempering reactor to obtain ferric chloride homogeneous liquid (Fe 3+ : 20.5%, Fe 2+ : 0.04%, HCl: 0.34%), feed cooling water into the jacket of the quenching and tempering reactor to reduce the material temperature to 33°C. Transfer the material liquid into the crystallization kettle, open and set the stirring speed to be 40r / min, open the cooling water valve to maintain the material temperature at 31°C, add 0.5% ferric chloride seed crystals for the first crystallization, and the material residence time is 1.5 hours to obtain The ferric chloride crystal slurry with a solid content of 20% enters the thickener to increase the solid content of the ferric chloride crystal slurry to 40%. Treatment...

Embodiment 2

[0041] Pump the ferric chloride solution into the evaporator to circulate and evaporate and concentrate at 100°C to 130°C to obtain concentrated ferric chloride (Fe 3+ : 24.0%, Fe 2+ : 0.06%, HCl: 0.26%). The mother liquor (Fe 3+ : 21.72%, Fe 2+ : 0.02%, HCl: 0.30%) stirred in the tempering reactor, and added an appropriate amount of low-concentration ferric chloride solution to obtain ferric chloride homogeneous liquid (Fe 3+ : 22.0%, Fe 2+ : 0.02%, HCl: 0.26%), feed cooling water into the jacket of the quenching and tempering reactor to reduce the material temperature to 35°C. Transfer the material liquid into the crystallization kettle, open and set the stirring speed to be 70r / min, open the cooling water valve to maintain the material temperature at 33°C, add 1% ferric chloride seed crystals during the first crystallization, and the material residence time is 1h to obtain The ferric chloride crystal slurry with a solid rate of 30% enters the thickener to increase the ...

Embodiment 3

[0043] Pump the ferric chloride solution into the evaporator to circulate and evaporate and concentrate at 100°C to 130°C to obtain concentrated ferric chloride (Fe 3+ : 22.0%, Fe 2+ : 0.02%, HCl: 0.28%). The mother liquor (Fe 3+ : 21.72%, Fe 2+ : 0.02%, HCl: 0.14%) stirred in the conditioning reactor, and added an appropriate amount of water to obtain ferric chloride homogeneous liquid (Fe 3+ : 21.0%, Fe 2+ : 0.01%, HCl: 0.16%), feed cooling water into the jacket of the quenching and tempering reactor to reduce the material temperature to 34°C. Transfer the material liquid into the crystallization kettle, open and set the stirring speed as 60r / min, open the cooling water valve to maintain the material temperature at 32°C, add 0.7% ferric chloride seed crystals during the first crystallization, and the material residence time is 1.2 hours to obtain The ferric chloride crystal slurry with a solid content of 25% enters the thickener to increase the solid content of the ferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com