A kind of preparation method of lignin micro/nanosphere

A lignin and nanosphere technology, applied in nanotechnology and other directions, can solve the problems of complicated operation, difficult large-scale production, and high equipment requirements, and achieve the effects of cheap reagents, environmentally friendly process, and low risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

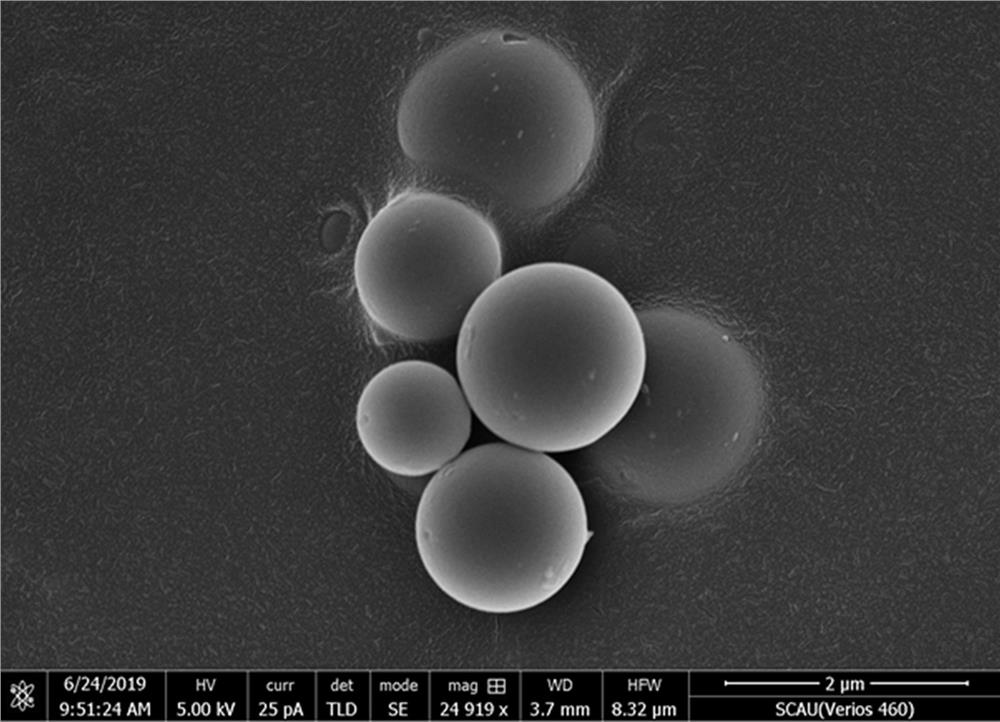

Embodiment 1

[0043] According to technical scheme A, a kind of preparation method of lignin microsphere with smooth surface comprises the following steps:

[0044] (1) Dissolve 1 g of organic solvent lignin in 400 mL of dichloromethane, then add 400 mL of water, and emulsify with a high-speed dispersing emulsifier at a speed of 10,000 r / min for 60 s to obtain a stable and uniform emulsion;

[0045] (2) The emulsion obtained in step (1) was stirred at a constant speed (200 rpm) for 3 h in an open environment at a temperature of 25°C until all the organic solvents evaporated to obtain a lignin microsphere-water mixture;

[0046] (3) Take out the mixed liquid obtained in step (2) and put it into a centrifuge, adjust the rotating speed to 8000 r / min, centrifuge for 10 min, repeat the centrifugation twice, remove the centrifuged liquid and then repeat the centrifugation at a centrifugal speed of 2000 r / min, wash After the lignin ball is colorless to the centrifugal liquid, take the solid in the...

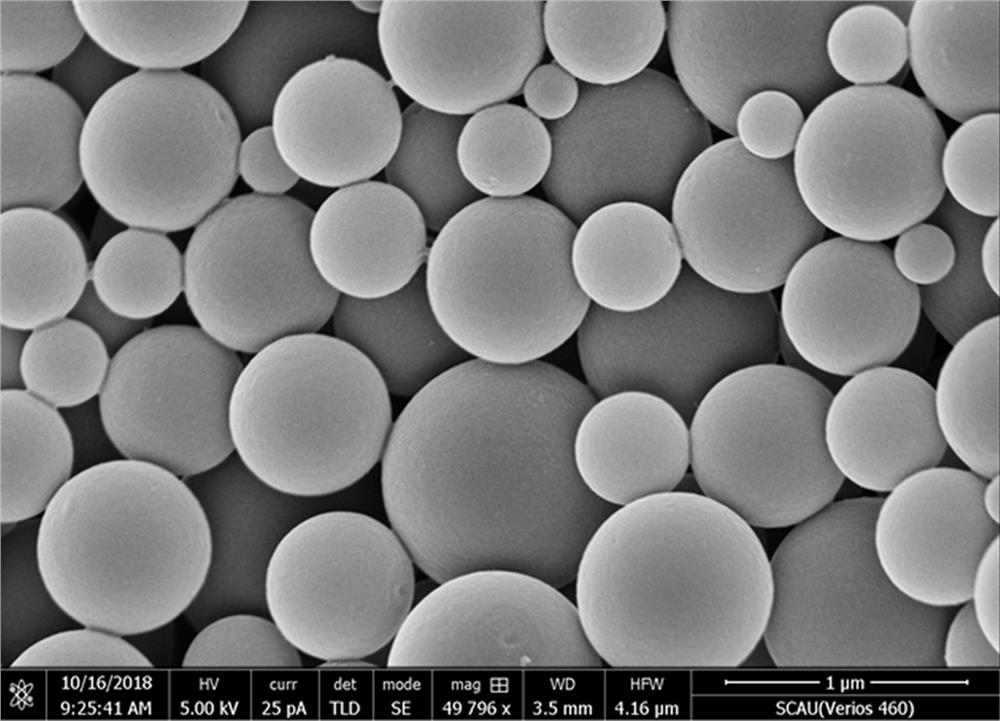

Embodiment 2

[0049] According to technical scheme A, a kind of preparation method of lignin nanosphere with smooth surface comprises the following steps:

[0050] (1) Dissolve 1 g of organic solvent lignin in 400 mL of ethyl acetate, then add 400 mL of aqueous solution containing polyvinyl alcohol (0.2% by mass fraction), and use a high-speed dispersing emulsifier at a speed of 10,000 r / min Emulsify for 30 s to obtain a stable and uniform emulsion;

[0051] (2) The emulsion obtained in step (1) was stirred at a constant speed (500 rpm) for 3 h in an open environment at a temperature of 25°C until all organic solvents were evaporated to obtain a lignin nanosphere-water mixture;

[0052] (3) Take out the mixed liquid obtained in step (2) and put it into a centrifuge, adjust the rotation speed to 10000 r / min, centrifuge for 15 min, repeat the centrifugation twice, remove the centrifugate and then repeat the centrifugation at a centrifugal speed of 2000 r / min, wash After the lignin ball is co...

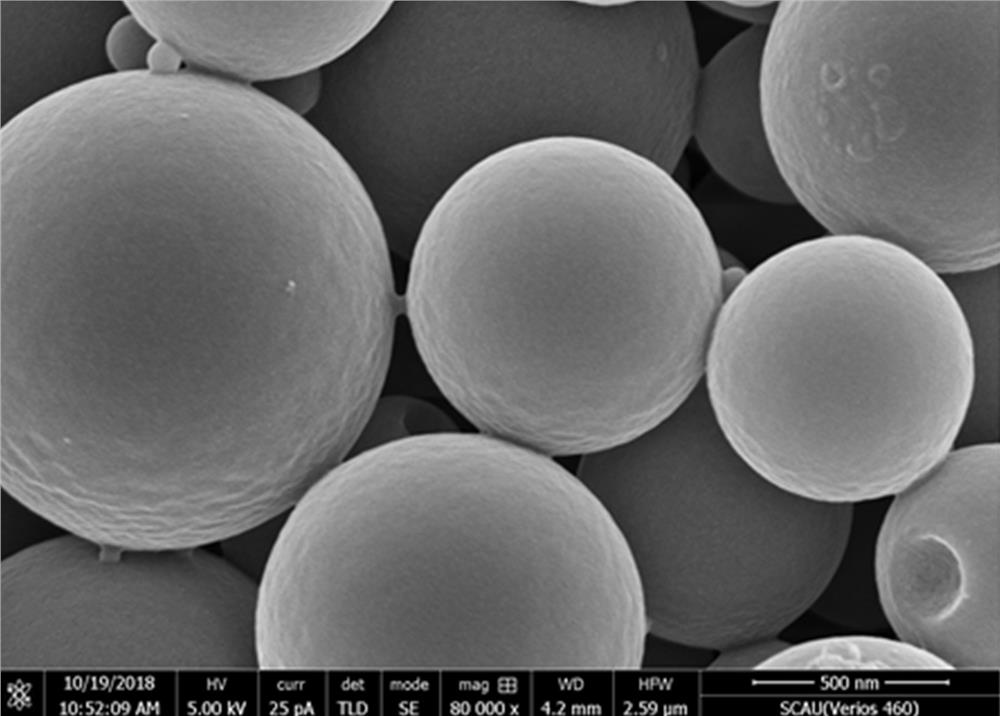

Embodiment 3

[0055] According to technical scheme A, a kind of preparation method of lignin nanosphere with smooth surface comprises the following steps:

[0056] (1) Dissolve 1 g of organic solvent lignin in 400 mL of dichloromethane, then add 400 mL of an aqueous solution containing sodium dodecylbenzenesulfonate (1% mass fraction), and use a high-speed dispersing and emulsifying machine at 10,000 Emulsify at a speed of r / min for 30 s to obtain a stable and uniform emulsion;

[0057] (2) The emulsion obtained in step (1) was stirred at a constant speed (500 rpm) for 3 h in an open environment at a temperature of 25°C until all organic solvents were evaporated to obtain a lignin nanosphere-water mixture;

[0058] (3) Take out the mixed liquid obtained in step (2) and put it into a centrifuge, adjust the rotation speed to 10000 r / min, centrifuge for 15 min, repeat the centrifugation twice, remove the centrifugate and then repeat the centrifugation at a centrifugal speed of 2000 r / min, wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com