AlGaN-based ultraviolet LED device and preparation method and application thereof

A technology of LED devices and epitaxial layers, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of large surface roughness, high film content, and no phase separation of components involved, and achieve the carrier-limited threshold effect. , increasing the radiation recombination efficiency and improving the surface morphology of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

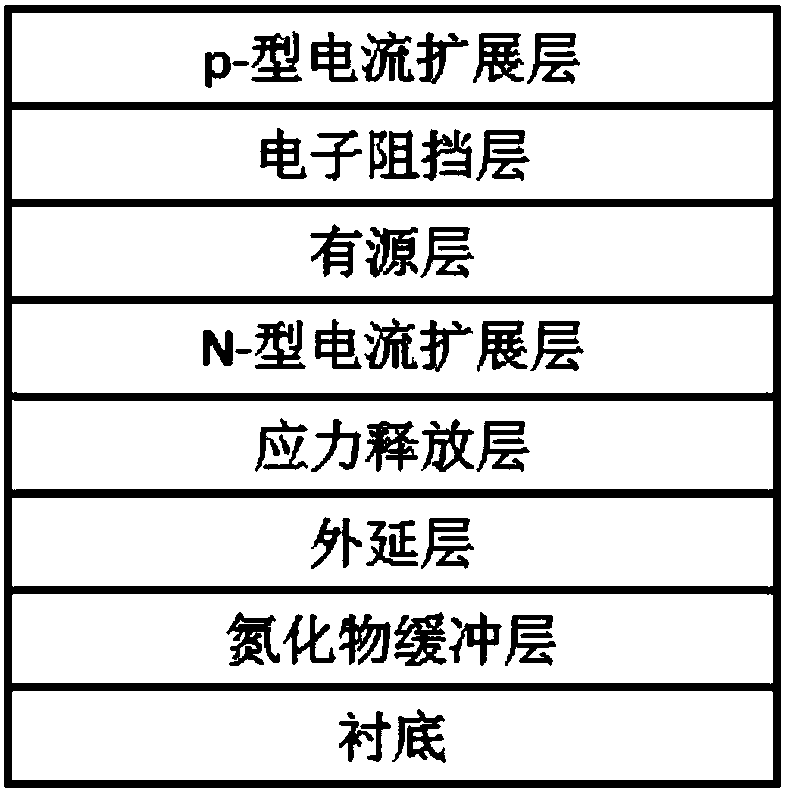

[0026] An aspect of the embodiments of the present invention provides a method for manufacturing an AlGaN-based ultraviolet LED device, which includes:

[0027] growing and forming a nitride buffer layer on the substrate, and pretreating the nitride buffer layer, wherein the pretreatment includes any one of plasma treatment, high temperature thermal annealing treatment and metal organic source precursor pretreatment or a combination of two or more; then sequentially form an epitaxial layer, a stress release layer, an n-type current spreading layer, a multilayer quantum well active layer, an electron blocking layer and a p-type current spreading layer on the nitride buffer layer .

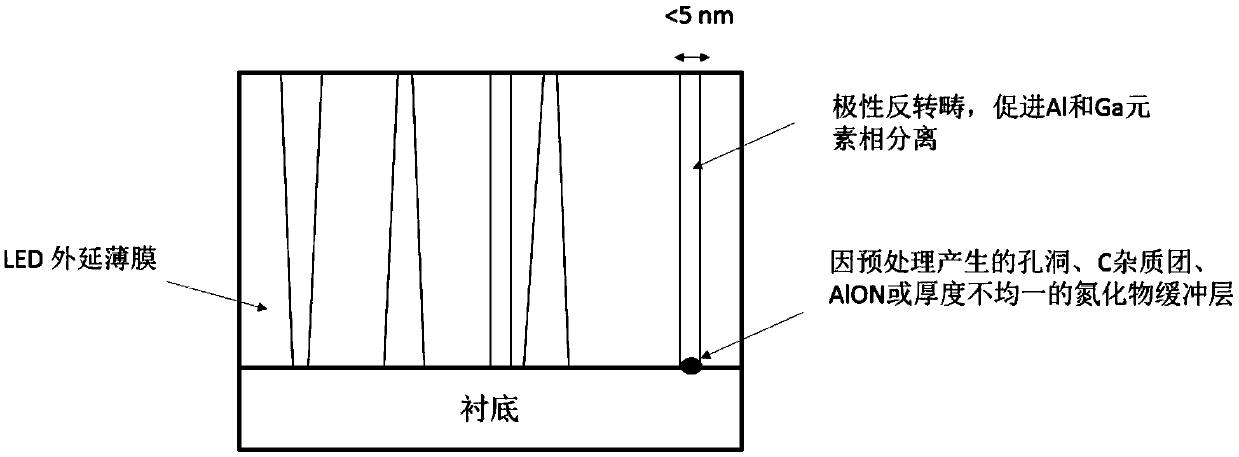

[0028] The mechanism that the present invention carries out pretreatment to nitride buffer layer may be: see figure 2 As shown, plasma treatment, high-temperature annealing, or pretreatment of nitride buffer film with MO precursors cause fluctuations in the film thickness of the buffer layer, resu...

Embodiment 1

[0064] A 10nm thick AlN buffer film was deposited on a sapphire substrate (2 inches in diameter and 430 microns in thickness) based on low-temperature MOCVD, and the deposition temperature of the buffer layer was 800°C. Use plasma treatment for 10min, etching conditions are 10mtorr, RF / ICP: 100 / 300W, Cl / BCl 3 : 10 / 25 sccm. Afterwards, put the substrate back into the MOCVD chamber, grow an AlN epitaxial layer of 50nm at high temperature, the growth temperature is 1200°C, V / III=300, then lower the temperature to 1150°C, keep the pressure at 200torr, and grow a 700nm thick AlN epitaxial layer 0.7 Ga 0.3 N to Al 0.3 Ga 0.7 A stress relief layer with gradually decreasing N-Al components. Then grow 2 micron thick n-Al 0.3 Ga 0.7 N500nm, the carrier concentration is 1×10 19 cm -3 , then lower the temperature to 1050°C, and grow five cycles of Al 0.3 Ga 0.7 N / GaN multi-quantum well active layer, the thickness of the GaN potential well in each period is 2nm, Al 0.3 Ga 0.7 T...

Embodiment 2

[0067] This embodiment is basically the same as Embodiment 1, the difference is: plasma treatment for 5 minutes, etching conditions of 200mtorr, RF / ICP: 150 / 20W, Cl / BCl 3 : 20 / 150sccm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com