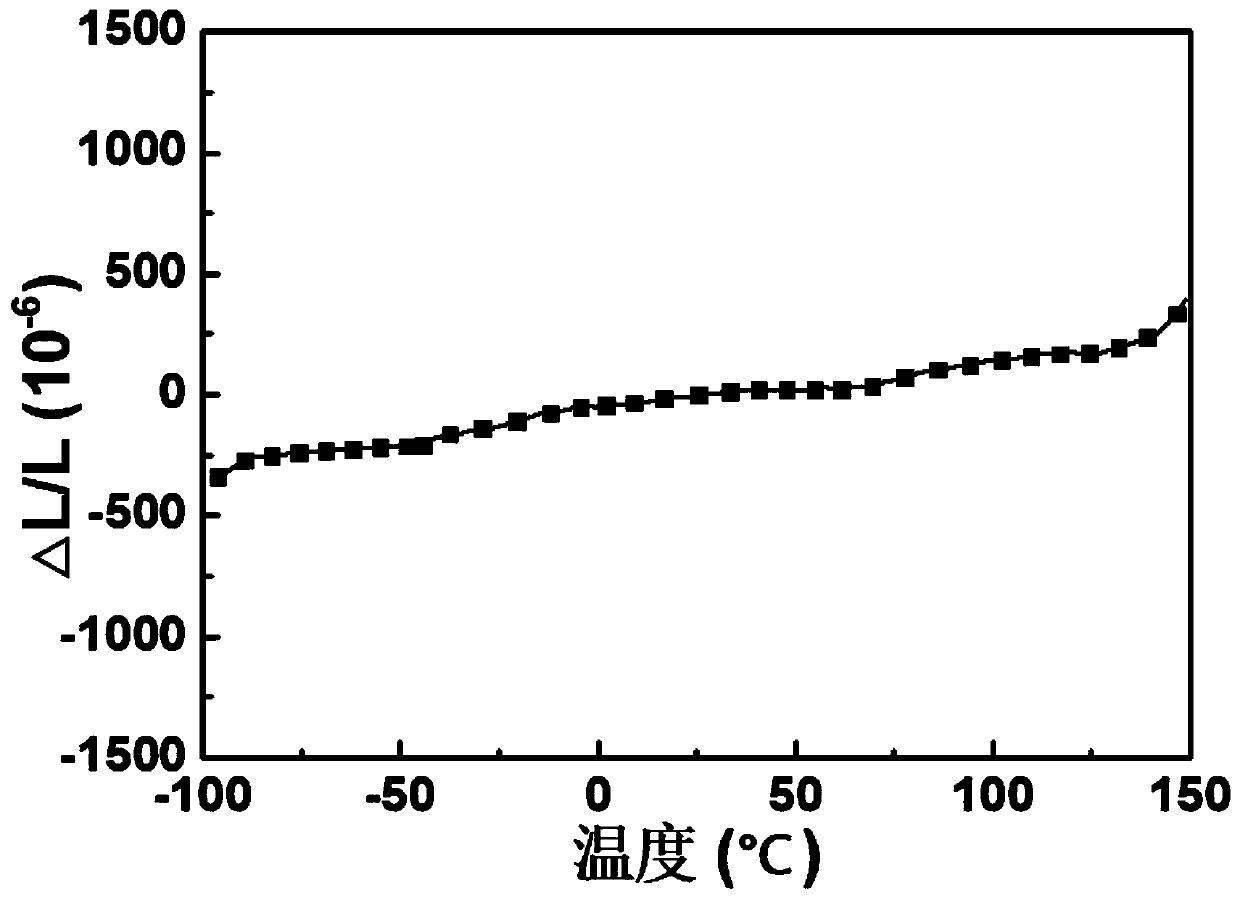

Preparation method of bronze alloy with near zero thermal expansion property

A bronze alloy and thermal expansion technology, applied in the field of material preparation, can solve problems such as poor electrical and thermal conductivity, large thermal expansion coefficient, and poor corrosion resistance, and achieve easy industrialized mass production, good electrical and thermal conductivity, and good corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing a bronze alloy with near-zero thermal expansion, characterized in that it comprises the steps of:

[0022] (1) According to mass percentage, copper is 74-83%, manganese is 9%-13%, and aluminum is 8-13%. Respectively take pure copper, pure aluminum, pure manganese as raw materials, or intermediate alloys including copper-manganese alloys, copper-aluminum alloys, etc. as raw materials.

[0023] (2) After the raw metal in step 1 is melted in a heating furnace, it is cast into a crystallizer mold, and the ingot is taken out after the metal is cooled and solidified. Then the ingot is reheated to 800° C. for 30 minutes, then water-cooled and quenched, and then the oxide layer on the surface of the ingot is removed by machining to obtain a copper-aluminum-manganese alloy material.

[0024] (3) The copper-aluminum-manganese alloy material obtained in step 2 is subjected to hot-rolling deformation of 50% to 90% of the multi-pass unidirectional deformation...

Embodiment 1

[0030] A method for preparing Cu-8.8wt.%Al-10.6wt.%Mn-1.5wt.%Ni alloy plate with near-zero thermal expansion performance, the method is as follows:

[0031] (1) According to mass percentage, copper is 79.1%, manganese is 10.6%, aluminum is 8.8%, and nickel is 1.5%. Electrolytic pure copper, pure aluminum, and pure manganese are respectively weighed as raw materials.

[0032] (2) After the raw metal in step 1 is melted in an electromagnetic induction heating furnace, it is cast into an axially heated graphite crystallizer mold with a diameter of 100mm and bottom water cooling, and the ingot is taken out after the metal is cooled and solidified. Then the ingot is reheated to 800° C. for 30 minutes, then water-cooled and quenched, and then the oxide layer on the surface of the ingot is removed by machining to obtain a Cu-Al-Mn-Ni alloy material.

[0033] (3) The copper-aluminum-manganese alloy material obtained in step 2 is subjected to three passes of hot rolling deformation alo...

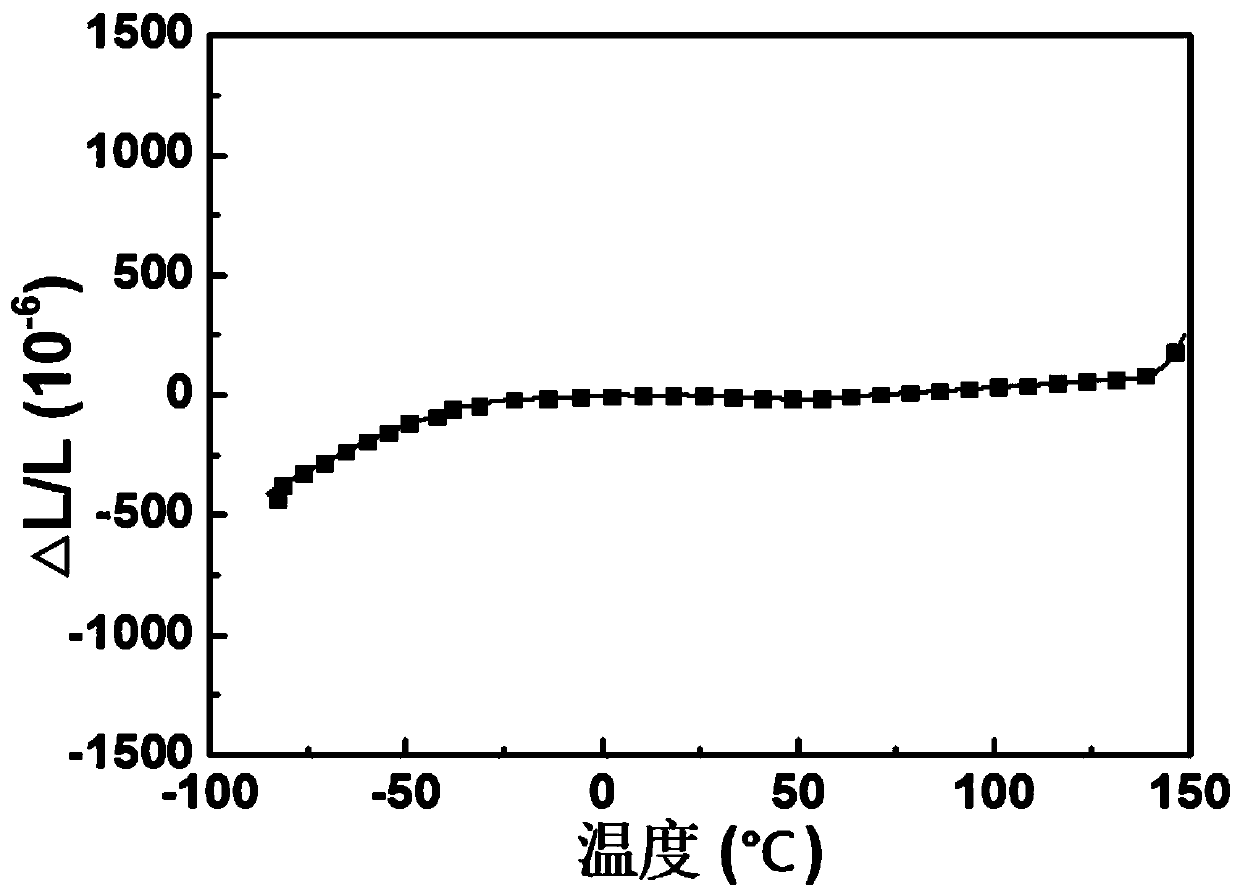

Embodiment 2

[0038] A method for preparing Cu-9wt.%Al-11wt.%Mn-0.5wt.%Ni-0.5wt.%Ti alloy strip with near-zero thermal expansion performance, the method is as follows.

[0039] (1) According to mass percentage, copper is 79%, manganese is 11%, aluminum is 9%, nickel is 0.5%, and titanium is 0.5%. Electrolytic pure copper, pure aluminum, and pure manganese are respectively weighed as raw materials.

[0040](2) After the raw metal in step 1 is melted in a resistance furnace heating furnace, it is cast into a graphite crystallizer mold with a diameter of 30 mm, and the ingot is taken out after the metal is cooled and solidified. Then the ingot is reheated to 800° C. for 30 minutes, then water-cooled and quenched, and then the oxide layer on the surface of the ingot is removed by machining to obtain a Cu-Al-Mn-Ni-Ti alloy material.

[0041] (3) The copper-aluminum-manganese alloy material obtained in step 2 is subjected to 4 passes of hot-rolled deformation along the axial direction at 800°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com