White opacity glaze, white opacity glaze ceramic product and preparation method thereof

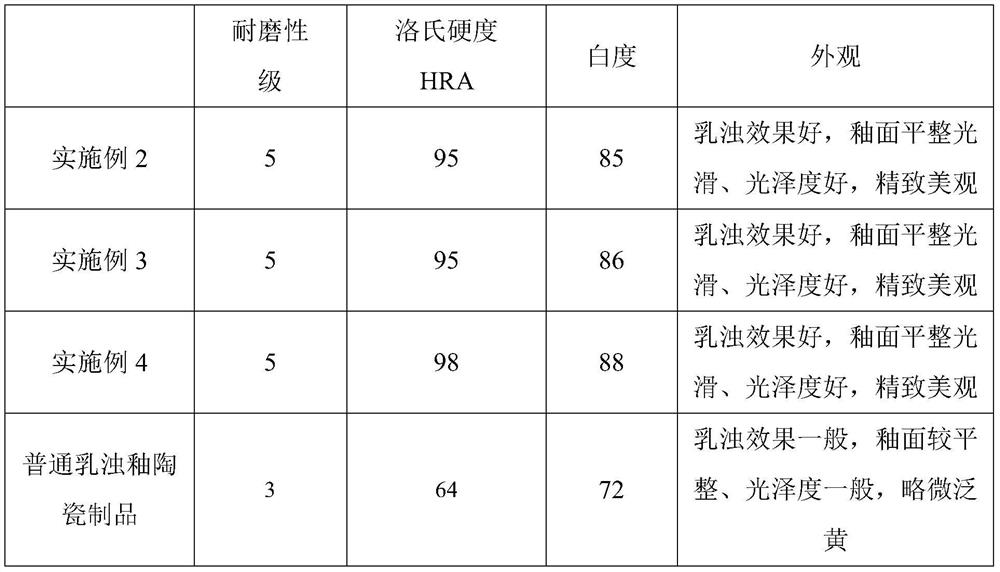

A technology of ceramic products and opacified glaze, which is applied in the field of ceramic products, can solve the problems of insufficient opacity effect of glaze surface, poor wear resistance of glaze surface, and not exquisite appearance, etc., and achieve good opacification effect and smooth glaze surface , Improve the effect of quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A white opacified glaze, comprising the following raw materials in parts by weight: 20-25 parts of potassium feldspar, 22-27 parts of albite, 8-12 parts of calcite, 16-20 parts of quartz, 10-14 parts of talc, bentonite 4.5-5.5 parts, 6-8 parts of strontium oxide, 5-7 parts of barium oxide, 6-9 parts of magnesium oxide, 5-6 parts of titanium oxide, 2.5-3.5 parts of barium zirconate titanate, 15-20 parts of zirconium silicate, 4-6 parts of yttrium oxide.

[0029] Preferably, the white opaque glaze includes the following raw materials in parts by weight: 22 parts of potassium feldspar, 24.5 parts of albite, 10.5 parts of calcite, 18.4 parts of quartz, 12 parts of talcum powder, 5 parts of bentonite, 7.5 parts of strontium oxide, 6.2 parts of barium oxide, 7.7 parts of magnesium oxide, 5.5 parts of titanium oxide, 3.1 parts of barium zirconate titanate, 18 parts of zirconium silicate, and 5 parts of yttrium oxide.

[0030] Preferably, the white opaque glaze further include...

Embodiment 2

[0041] A white opaque glaze, comprising the following raw materials in parts by weight: 20 parts of potassium feldspar, 22 parts of albite, 8 parts of calcite, 16 parts of quartz, 10 parts of talcum powder, 4.5 parts of bentonite, 6 parts of strontium oxide, barium oxide 5 parts, 6 parts of magnesium oxide, 5 parts of titanium oxide, 2.5 parts of barium zirconate titanate, 15 parts of zirconium silicate, and 4 parts of yttrium oxide.

[0042] In this embodiment, the white opaque glaze further includes the following raw materials in parts by weight: 4 parts of high boron frit.

[0043] In this embodiment, the titanium oxide is nano titanium dioxide.

[0044] In this embodiment, the boron content of the high boron frit is 10%, and the lead content is less than 0.01%.

[0045] The present invention also provides a white opaque glaze ceramic product, comprising a body and a glaze layer covering the surface of the body, the glaze layer being the aforementioned white opaque glaze. ...

Embodiment 3

[0052] A white opaque glaze, comprising the following raw materials in parts by weight: 25 parts of potassium feldspar, 27 parts of albite, 12 parts of calcite, 20 parts of quartz, 14 parts of talcum powder, 5.5 parts of bentonite, 8 parts of strontium oxide, barium oxide 7 parts, 9 parts of magnesium oxide, 6 parts of titanium oxide, 3.5 parts of barium zirconate titanate, 20 parts of zirconium silicate, and 6 parts of yttrium oxide.

[0053] In this embodiment, the white opaque glaze further includes the following raw materials in parts by weight: 7 parts of high boron frit.

[0054] In this embodiment, the titanium oxide is nano titanium dioxide.

[0055] In this embodiment, the boron content of the high boron frit is 15%, and the lead content is less than 0.01%.

[0056] The present invention also provides a white opaque glaze ceramic product, comprising a body and a glaze layer covering the surface of the body, the glaze layer being the aforementioned white opaque glaze....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com