A kind of method for synthesizing 1,4-butanediol by hydrogenation of 1,4-butynediol

A technology of butynediol and butanediol, which is applied in chemical instruments and methods, preparation of organic compounds, hydrogenation preparation, etc., can solve the problems of increased fixed capital investment, increased separation cost, large energy consumption, etc., and achieves by-products Fewer types, lower separation costs, and easier separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0035] The preparation of embodiment 1~8 one-stage hydrogenation reaction catalyst 1~8

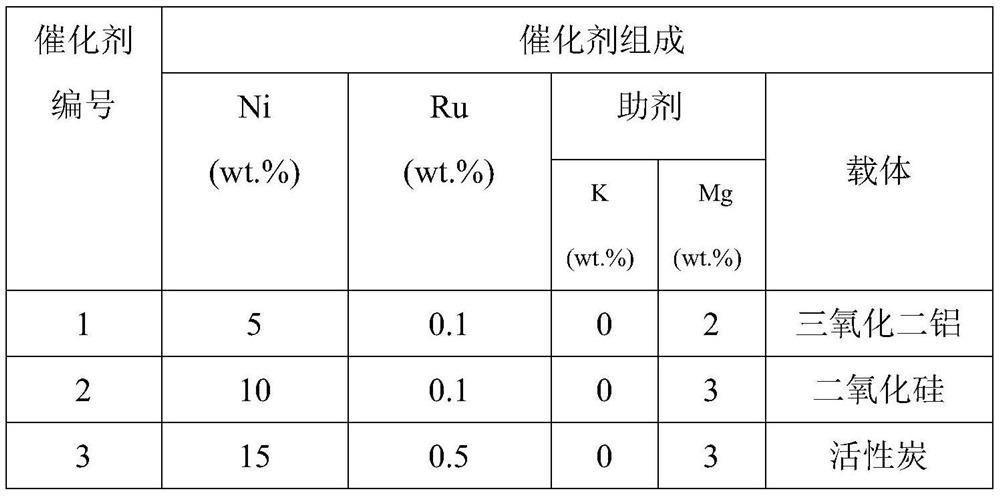

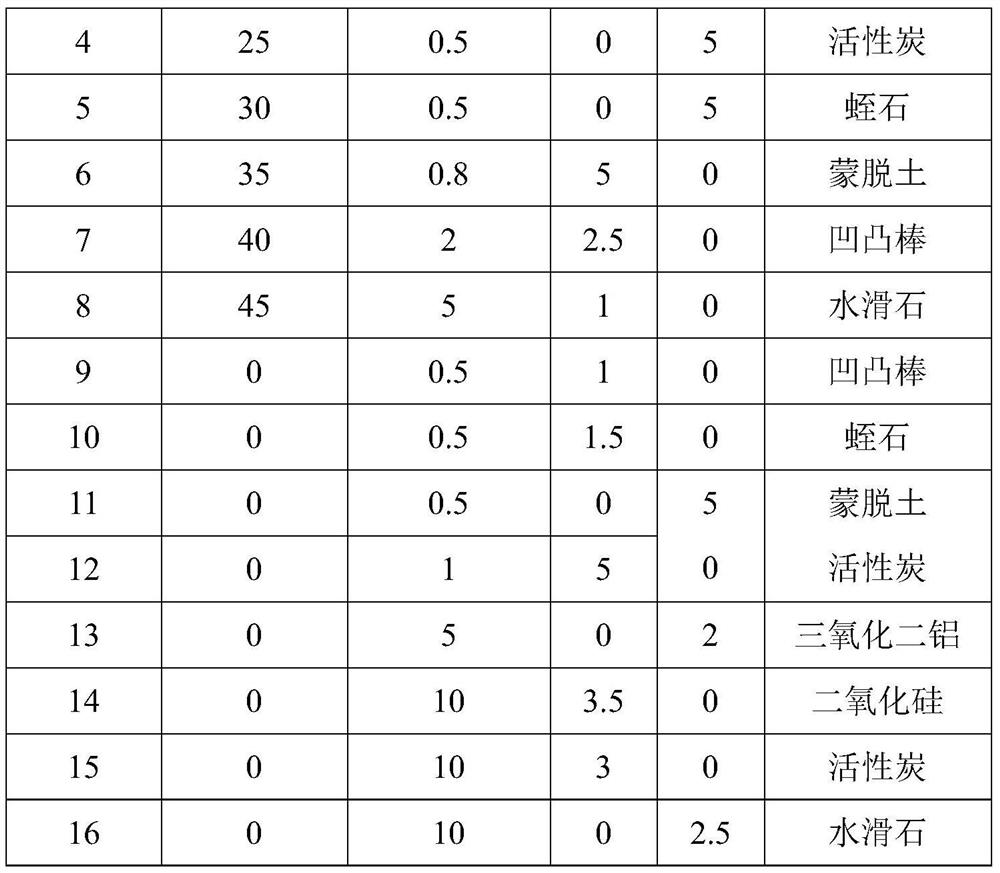

[0036] The compositions of the one-stage hydrogenation reaction catalysts 1 to 8 are shown in Table 1.

[0037] Weigh a certain amount of ruthenium trichloride, nickel nitrate, and the soluble salt of the auxiliary agent and dissolve them in 50 mL of water, then add 3 g of carrier, and continue to stir for 6 h; then add 1 mol / L ammonia water to adjust pH=9 to 10, and continue to stir for 4 h , left to stand overnight; suction filtration, washed with deionized water, dried at 120 °C, calcined at 700 °C in argon for 2 h, and reduced in a hydrogen atmosphere at a temperature of 300 °C for 3 h to obtain a hydrogenation reaction catalyst 1-8 (see Table 1). 1).

Embodiment 9~16

[0038] Examples 9-16 Preparation of two-stage hydrogenation catalysts 9-16

[0039] The compositions of the two-stage hydrogenation reaction catalysts 9 to 16 are shown in Table 1.

[0040] Dissolve a certain amount of ruthenium trichloride and the soluble salt of the auxiliary agent in 30 mL of deionized water, then add 5 g of carrier, and continue to stir for 2 hours; then add 1 mol / L sodium hydroxide solution to adjust pH=9 to 10, and continue to stir for 4 hours , let stand overnight; suction filtration, wash with deionized water, dry at room temperature, roast in argon at 200 ° C for 6 h, and reduce in a hydrogen atmosphere at a temperature of 600 ° C for 8 h to obtain a two-stage hydrogenation reaction catalyst 9-16 ( See Table 1).

Embodiment 17

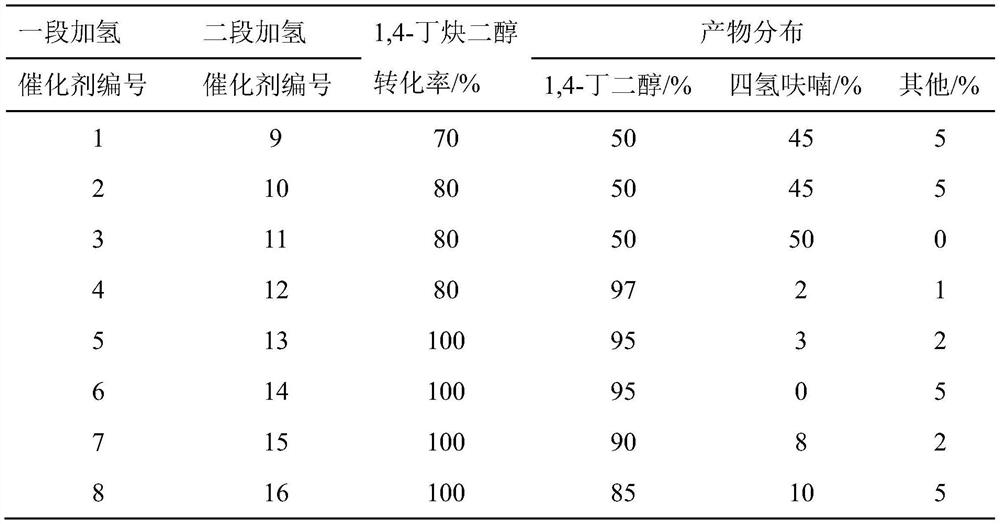

[0041] Example 17 Method for synthesizing 1,4-butanediol by hydrogenation of 1,4-butynediol

[0042] One-stage hydrogenation step: add 100 mL of 40% 1,4-butynediol aqueous solution to a 250-mL autoclave, add any one of the first-stage hydrogenation reaction catalysts 1 to 8, seal, replace with nitrogen for 4 times, and fill with hydrogen The pressure is increased to 2MPa, the temperature is raised to 130°C, and the stirring is continued until the pressure in the reaction kettle does not change.

[0043] Second-stage hydrogenation step: add the first-stage hydrogenation product into a 250 mL autoclave, add any one of the second-stage hydrogenation reaction catalysts 9 to 16, seal, replace with nitrogen for 4 times, fill with hydrogen to a pressure of 1 MPa, and heat up. When the temperature reaches 90°C, stirring is continued until the pressure in the reaction kettle does not change, and the catalyst is separated by releasing the pressure to obtain the final hydrogenated produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com