A kind that can absorb co 2 Acidification retarder for forming isolation layer, preparation method and application

A retarder and isolation layer technology, which is applied in the field of acidification retarder and preparation, can solve the problems of high acid fracturing construction pressure, low displacement, and reduced foam acid stability, and achieve the effect of reducing the degree of acid rock reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] One that can absorb CO 2 An acidification retarder forming an isolation layer, the acidification retarder is composed of a monomer solution and an initiator,

[0029] The material ratio of the monomer solution is: 4.0-6.0 wt% of acrylamide, 8.0-10.0 wt% of 2-acrylamide-2-methylpropanesulfonic acid, perfluoroalkyl amidopropyl dimethyl allyl chloride 0.1-1.0 wt% ammonium chloride, 1.0-10.0 wt% ammonium sulfate, 5-25 wt% sodium hydroxide solution with a concentration of 10% by mass, and the balance is water;

[0030] The initiator is composed of 1.0% potassium persulfate by mass percentage concentration and 1.0% 2,3,5,6-tetrahydroxy-2-hexenoic acid-4-lactone by mass percentage concentration. The dosage of body solution is 2.0-6.0wt% and 1.0-4.0wt% respectively.

[0031] The described one can absorb CO 2 Form the preparation method of the acidification retarder of isolation layer, this preparation method comprises the following steps:

[0032] Step 1: acrylamide, 2-acry...

Embodiment 2

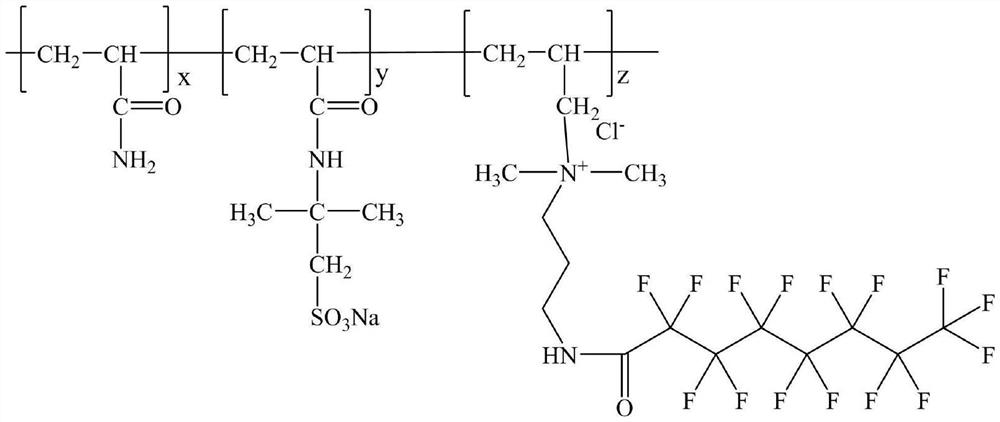

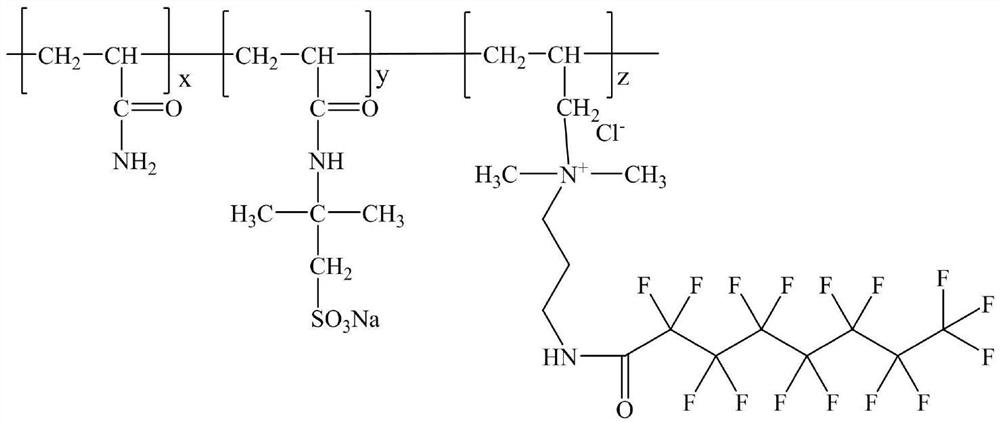

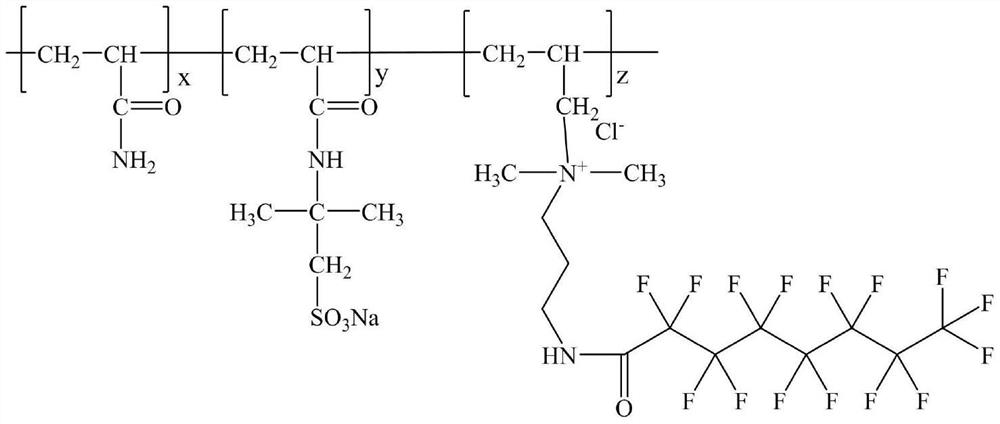

[0041] On the basis of Example 1, the described one can absorb CO 2 The molecular structural formula of the acidification retarder forming the isolation layer is as follows:

[0042]

[0043] Wherein, X, Y, and Z are respectively the number of moles of the corresponding units, and the ratio of the number of moles of X, Y, and Z is:

[0044] X:Y:Z=(6-10):(4-6):(0.01-0.3).

Embodiment 3

[0047] Add acrylamide 5wt%, 2-acrylamide-2-methylpropanesulfonic acid 10.0wt%, perfluoroalkyl amidopropyl dimethyl allyl ammonium chloride 0.1wt%, ammonium sulfate 4.90wt% in a 2000mL three-necked flask wt% and 40.0wt% water, start stirring until completely dissolved, add 10% sodium hydroxide to dissolve 20.0wt%, adjust pH=6.35, add 20.0wt% water to obtain a monomer solution;

[0048]At a temperature of 25°C, pass nitrogen to the monomer solution for 30 minutes to remove oxygen, then add 1.0% potassium persulfate aqueous solution of 4.0 wt%, continue to pass nitrogen for 5 minutes, and add 1.0% by mass concentration 2,3,5,6 -Tetrahydroxy-2-hexenoic acid-4-lactone aqueous solution 2.0wt%. When the reaction starts, the temperature rises and the viscosity increases. When the temperature is higher than 45°C, heat the reaction at 50°C in a water bath for 8 hours to obtain a colorless transparent acidified slow Accelerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com