Multi-responsive shape memory urethane acrylate copolymer and preparation method thereof

A technology of urethane acrylate and copolymer, which is applied in the field of preparation of urethane acrylate-based copolymers, and can solve problems such as not found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation of PUA prepolymer is:

[0031] (1) Synthesis of polycaprolactone polyol: Add 1,4-butanediol and ε-caprolactone in a round bottom flask, BDO: ε-CL molar ratio is 1:16, catalyst stannous octoate, pass into N 2 Raise the temperature to 130°C, react for 24 hours, and stop the reaction. Pour the obtained product into n-hexane and anhydrous ether for centrifugal purification, and dry it in a vacuum oven at 50°C for 24 hours to obtain PCL long-chain diol with a molecular weight of 2000.

[0032] (2) Preparation of PUA prepolymer: Put 0.01mol of PCL long-chain diol in a three-necked flask, heat it to 100°C and vacuumize it with a circulating water pump for 2 hours to remove moisture, then cool down to 50°C and add 0.02mol dropwise using a constant pressure separatory funnel HDI monomer and organic bismuth catalyst, toluene was added dropwise to reduce the viscosity of the system, nitrogen gas was introduced to remove the air in the flask, and the temperature w...

Embodiment 1

[0034]Weigh 4g of PUA prepolymer, add 1g of NIPAM monomer into a disposable plastic cup, add 10ml of DMF solvent and ultrasonically mix evenly, drop 0.5g of AAc monomer into the mixture, add 0.055g of PI184, stir to mix evenly , pour it into a polytetrafluoroethylene mold (80mm × 80mm × 1mm), use a PET film cover to remove the air on the surface and make the surface smooth, irradiate under a UV lamp for 20min, take out the film, rinse it with acetone solvent 3-5 times, and place Take it out in a vacuum oven at 50°C for 24 hours and cut it to the required size.

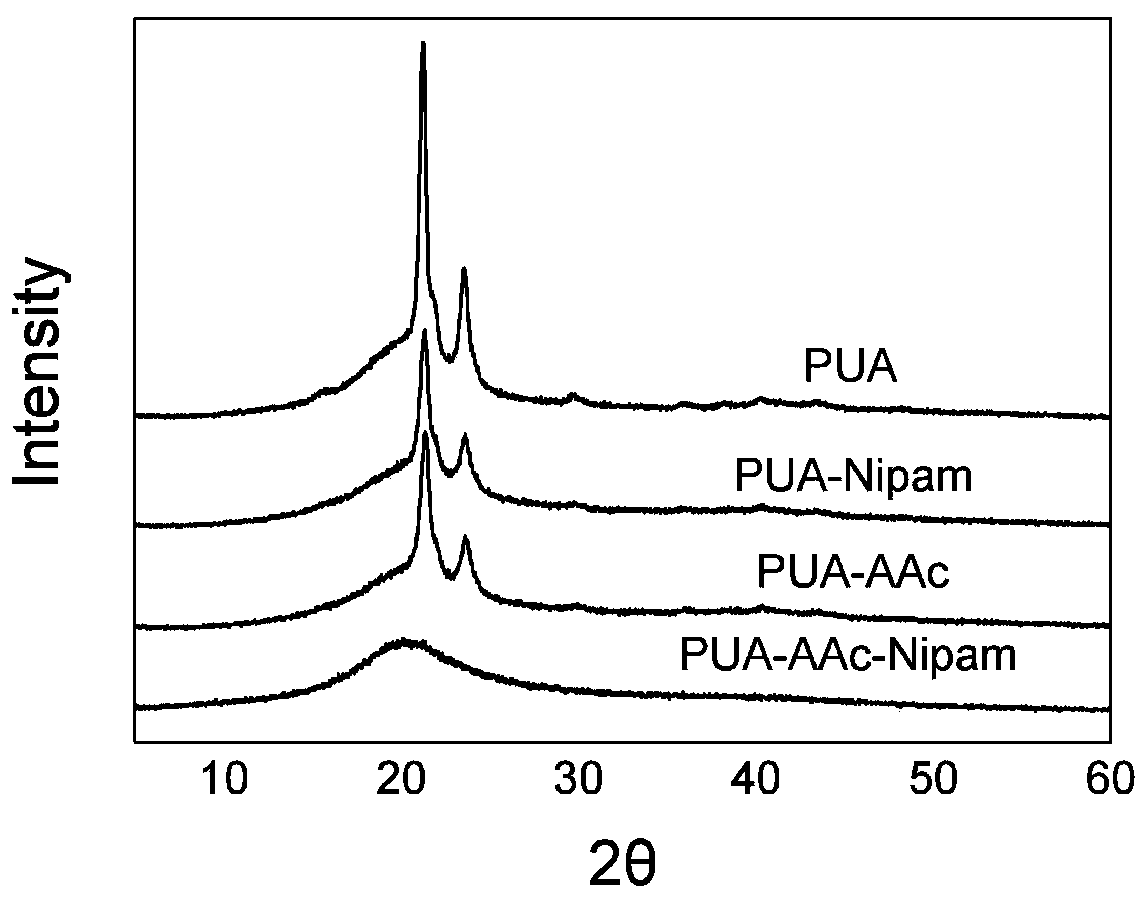

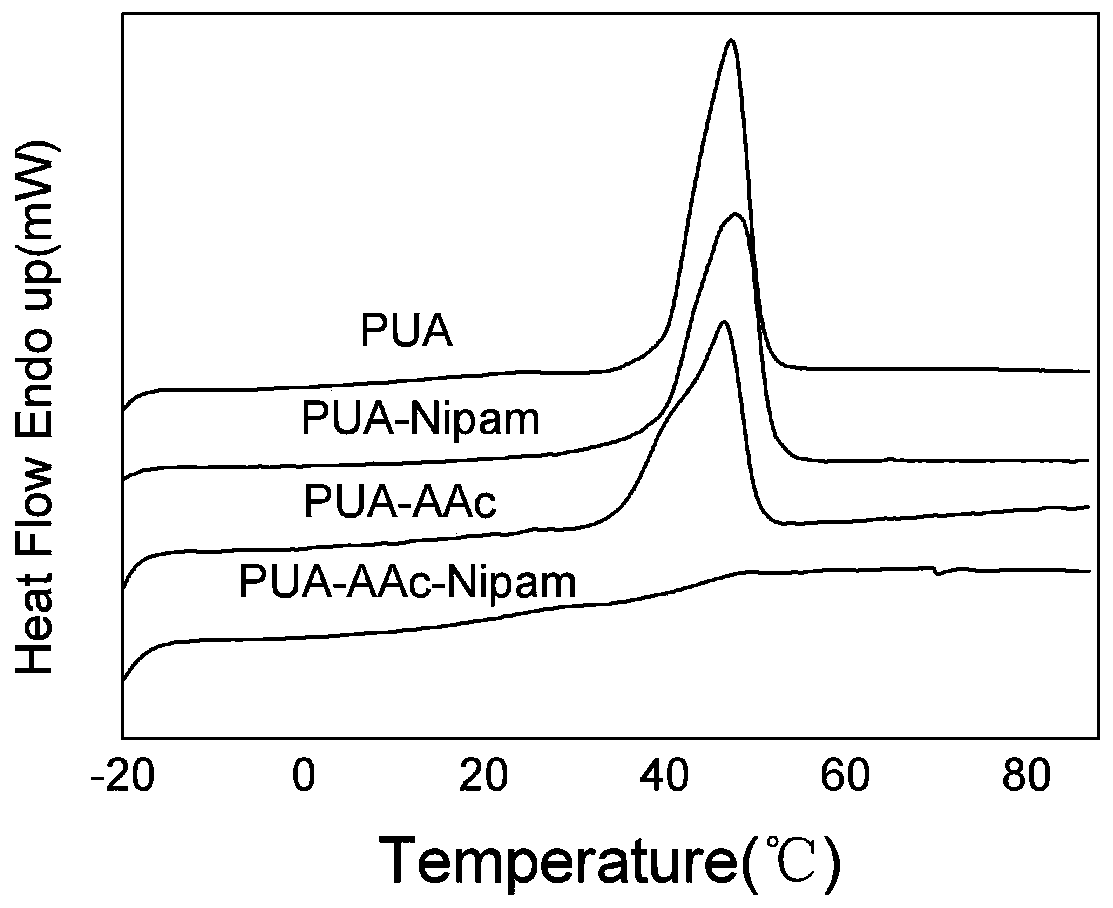

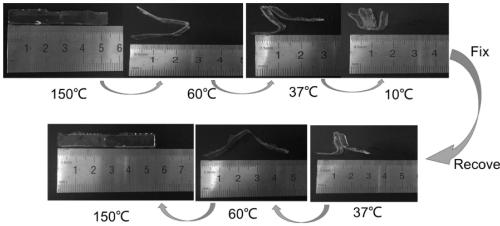

[0035] The prepared copolymer film was tested by XRD and DSC, and the drug release of tetracycline was studied to observe its shape memory effect.

Embodiment 2

[0037] Weigh 4g of PUA prepolymer, add 1g of NIPAM monomer into a disposable plastic cup, add 10ml of DMF solvent and ultrasonically mix evenly, drop 0.75g of AAc monomer into the mixture, add 0.058g of PI184, stir to mix evenly , pour it into a polytetrafluoroethylene mold (80mm × 80mm × 1mm), use a PET film cover to remove the air on the surface and make the surface smooth, irradiate under a UV lamp for 20min, take out the film, rinse it with acetone solvent 3-5 times, and place Take it out in a vacuum oven at 50°C for 24 hours and cut it to the required size.

[0038] The prepared copolymer film was tested by XRD and DSC, and the drug release of tetracycline was studied to observe its shape memory effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com