Relaxor ferroelectric ceramic with high electrocaloric effect at room temperature, and preparation method and applications thereof

A technology of electric card effect and ferroelectric ceramics, which is applied in the field of ferroelectric relaxation materials, can solve the problems of limited applied electric field strength, hindering the application of refrigerators, and low cooling degree, so as to improve mechanical properties and improve dielectric properties. properties, ferroelectricity, and the effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The relaxor ferroelectric ceramic with high electric card effect at room temperature has a chemical composition of: 0.9KNbO 3 -0.1BaTiO 3 (KN / BT(9 / 1)), the specific preparation process is as follows:

[0042] 1) Take Nb 2 o 5 、K 2 CO 3 As raw material, according to the chemical formula: KNbO 3 For batching, use absolute ethanol as the medium to wet grind for 2 hours, dry and press into large pieces Φ15*15mm 2 , placed in a muffle furnace and kept at 640°C for 2 hours for calcination; the calcined block was crushed through a 40-mesh sieve and then ball-milled for 24 hours, dried and passed through a 200-mesh sieve for use; the prepared KNbO 3 Powder and Nano BaTiO 3 By 0.9KNbO 3 -0.1BaTiO for preparation, mixed by ball milling and drying, after drying, pressed into large pieces Φ15*15mm 2 , put it into a muffle furnace for calcination at 900°C for 2 hours, smash the block material in a mortar, pass through a 40-mesh sieve, wet-grind with absolute ethanol as a me...

Embodiment 2

[0047] The relaxor ferroelectric ceramic with high electric card effect at room temperature has a chemical composition of: 0.85KNbO 3 -0.15BaTiO 3 (KN / BT=8.5 / 1.5), the specific preparation process is as follows:

[0048] 1) Take Nb 2 o 5 、K 2 CO 3 As raw material, according to the chemical formula: KNbO 3 For batching, wet grinding with absolute ethanol as the medium for 2.5 hours, after drying, press into large pieces Φ15*15mm 2 , placed in a muffle furnace and kept at 640°C for 1.5 hours for calcination; the calcined block was crushed through a 40-mesh sieve and then ball-milled for 24 hours, dried and passed through a 200-mesh sieve for use; the prepared KNbO 3 Powder and Nano BaTiO 3 According to 0.85KNbO 3 -0.15BaTiO for preparation, mixed by ball milling and drying, after drying, pressed into large pieces Φ15*15mm 2 , put it into a muffle furnace for calcination at 900°C for 5 hours, smash the block material in a mortar, pass through a 200-mesh sieve, use absolu...

Embodiment 3

[0052] Embodiment 3 test experiment

[0053] The relaxor ferroelectric ceramics of high electric card effect under the room temperature that adopts embodiment 1 preparation carries out following test as test sample:

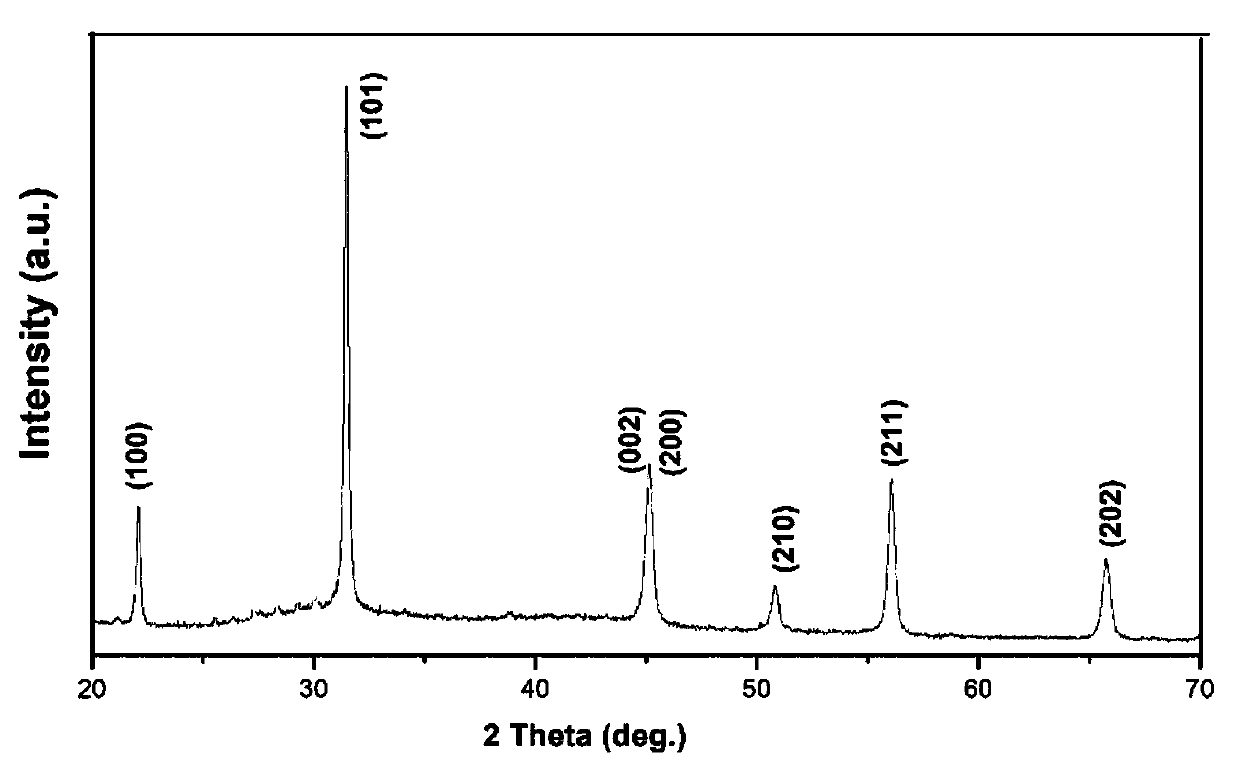

[0054] 1) Carry out XRD test at 1050°C, the XRD pattern is as follows figure 1 As shown, it can be found that the sample presents a pure KN-BT (9 / 1) perovskite structure at 1050 ° C;

[0055] 2) SEM was carried out on the natural surface and section of the sample, and the test results were as follows: figure 2 As shown, the natural surface is obviously composed of uniformly distributed fine grains and coarse grains, wherein the fine grains have a particle size of 0.2-0.5 μm, and the coarse grains have a particle size of 10-50 μm.

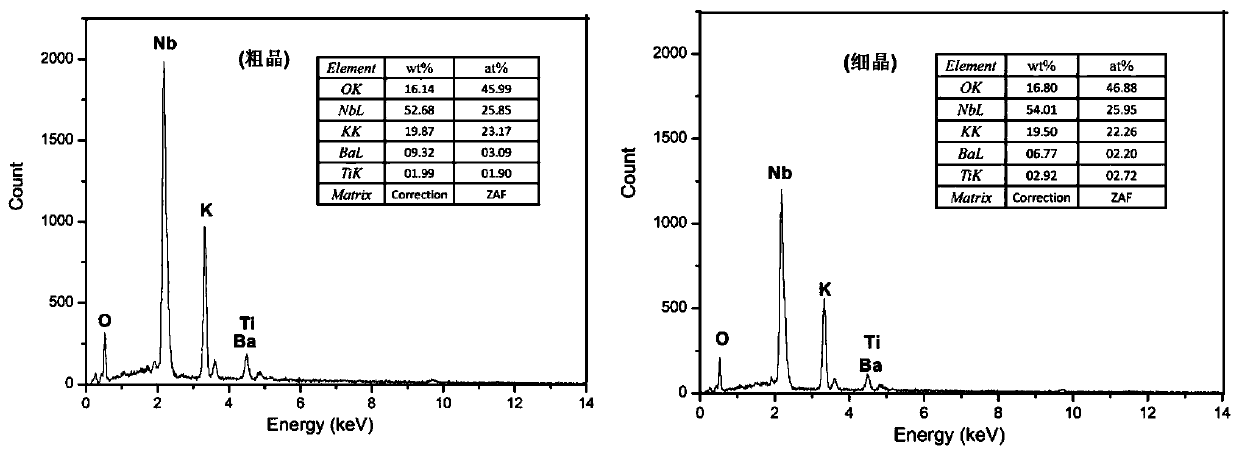

[0056] 3) EDS test and analysis of fine and coarse crystals in the sample, such as image 3 As shown, the molar ratios K:Nb and Ba:Ti are close to the stoichiometric ratio of 1:1, respectively, and the components do not segregate; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com