Biological organic fertilizer and preparation method thereof

A bio-organic fertilizer and composting technology, applied in the field of agricultural fertilizers, can solve the problems of reducing the number of effective viable bacteria of bio-organic fertilizer, polluting the environment and nutrition, and insignificant fertilizer efficiency, so as to solve the problem of sewage discharge, increase soil organic matter, and shorten the fermentation cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

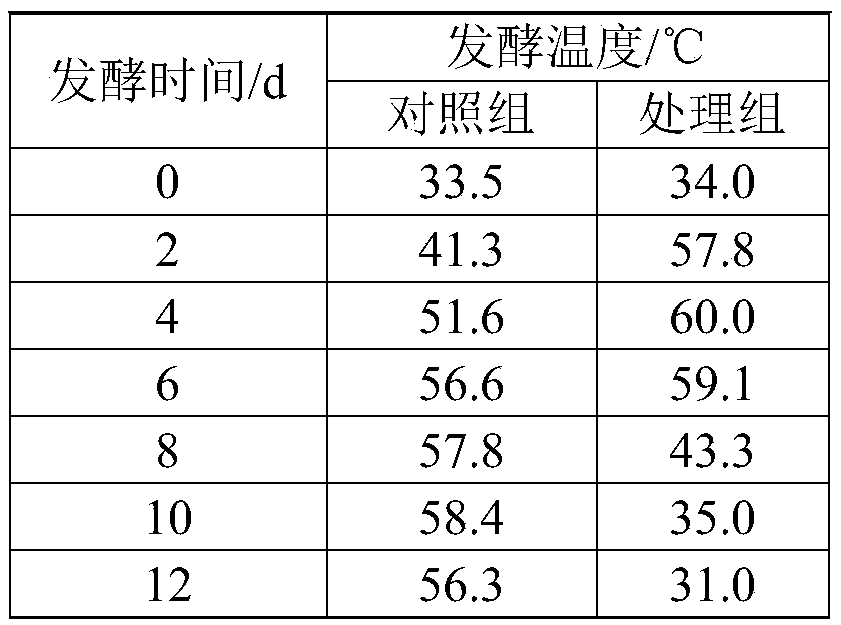

Image

Examples

Embodiment 1

[0034] A bio-organic fertilizer of the present invention is formed by mixing and fermenting the following raw materials in parts by weight: 50 parts of rapeseed meal, 10 parts of plant straw, 8 parts of garlic residue, 5 parts of bagasse, 8 parts of oyster shell powder, and 2 parts of calcium magnesium phosphate fertilizer , 6 parts of amino acid solution, 20 parts of sewage, 1 part of wood vinegar, 0.5 part of decomposed bacterial agent, and 1 part of composite functional bacterial agent; wherein, the plant straw is rice straw; the sewage is industrial sewage, domestic sewage and After the rainwater passes through the sewage treatment system, the sewage after adding wood vinegar; the decomposing bacteria agent is composed of Bacillus subtilis, Bacillus licheniformis, yeast, Aspergillus niger, Aspergillus oryzae, Trichoderma viride, Rhodospirillum and cellulase 8:2:4:4:4:3:3:10; the composite functional bacterial agent refers to 2:1:1.5:0.8 of Bacillus amyloliquefaciens, Bacill...

Embodiment 2

[0041]A high-efficiency bio-organic fertilizer, which is made by mixing and fermenting the following raw materials by weight: 60 parts of rapeseed meal, 20 parts of plant straw, 12 parts of garlic residue, 7 parts of bagasse, 12 parts of oyster shell powder, 30 parts of sewage, calcium magnesium phosphate fertilizer 6 parts, 10 parts of amino acid solution, 2 parts of wood vinegar solution, 1.5 parts of decomposed microbial agent, and 3 parts of composite functional microbial agent; wherein, the plant straw is composed of rice straw and rape straw mixed in equal proportions; the decomposed microbial agent is composed of subtilis Bacillus, Bacillus licheniformis, yeast, Aspergillus niger, Aspergillus oryzae, Trichoderma viride, Rhodospirillum and cellulase are mixed in the ratio of 8:2:4:4:4:3:3:10; composite The functional bacterial agent is 3:2:2:1.2 of Bacillus amyloliquefaciens, Bacillus jelly-like, Bacillus megaterium and Metarhizium anisopliae. The preparation method of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com