Preparation method and application of pressure stress coating of radar antenna housing or antenna window

A radome and antenna window technology, applied in the coating and other directions, can solve the problems of high carbon residue rate, affect the wave transmission performance, slow curing and other problems, achieve good dielectric properties, improve mechanical properties and heat resistance, reduce The effect of moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0030] 1. Add 2wt.% polyvinyl alcohol (PVA), 2wt.% boron carbide (B 4 C) powder and 1wt.% sodium dodecylbenzenesulfonate, heated to 96°C and stirred until PVA is completely dissolved, which is recorded as mixed solution 1.

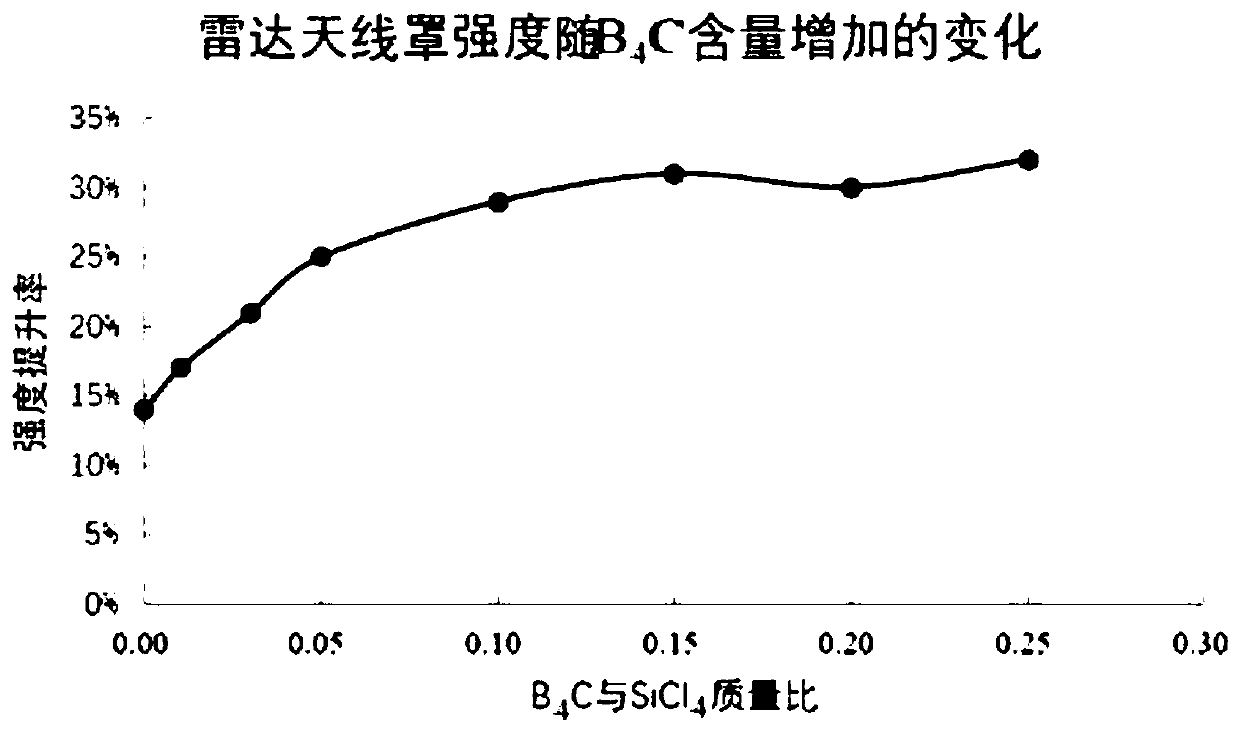

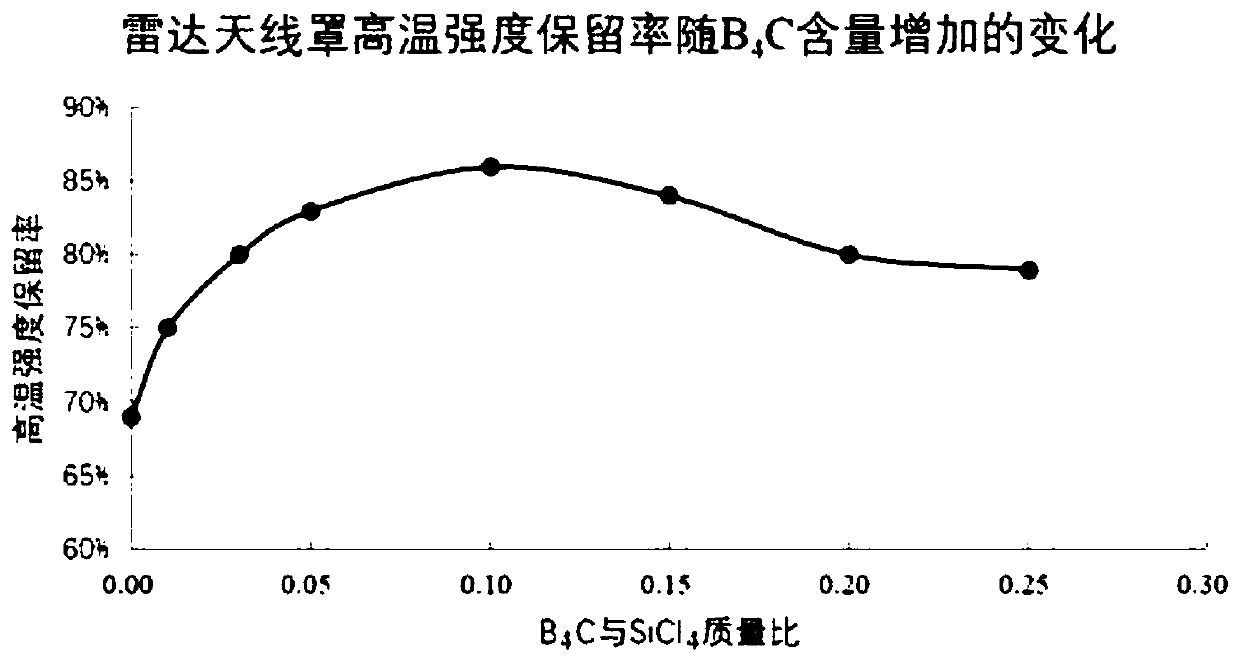

[0031] 2. Take an appropriate amount of mixed solution 1, and add tetrachlorosilane (SiCl 4 ), the water bath was kept at 50° C. and stirred for 1 hour to obtain the mixed solution 2. Among them, SiCl 4 with B 4 The mass ratio of C is 20:1.

[0032] 3. Add 20wt.% xylene and 2wt.% antioxidant to the monosilane, and stir until the silicone resin is completely dissolved in the organic solvent to obtain a mixed solution 3.

[0033] 4. Add the mixed solution 3 to the mixed solution 2 dropwise, keep the water bath at 50°C and stir until most of the water and organic solvents are volatilized, and dry in a muffle furnace at 50°C for 48 hours to obtain the mixture 4. Among them, silicone resin and SiCl 4 The mass ratio is 1:1.

[0034] 5. Take out the mixtur...

specific Embodiment 2

[0037] 1. Add 5wt.% polyvinyl alcohol (PVA), 5wt.% boron carbide (B 4 C) Powder and 1wt.% Tween 80, heated to 92°C and stirred until PVA was completely dissolved, which was recorded as mixed solution 1.

[0038] 2. Take an appropriate amount of mixed solution 1, and add tetrachlorosilane (SiCl 4 ), kept at 50°C in a water bath and stirred for 2 hours to obtain a mixed solution 2. Among them, SiCl 4 with B 4 The mass ratio of C is 10:1.

[0039] 3. Add 50wt.% acetone and 1wt.% antioxidant to the tetraethyl orthosilicate silicone resin, and stir until the silicone resin is completely dissolved in the organic solvent to obtain a mixed solution 3.

[0040] 4. Add the mixed solution 3 to the mixed solution 2 dropwise, keep the water bath at 50°C and stir until most of the water and organic solvents are volatilized, and dry in a muffle furnace at 50°C for 24 hours to obtain the mixture 4. Among them, silicone resin and SiCl 4 The mass ratio is 2:1.

[0041] 5. Take out the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com