Urine-excrement-separation environment-friendly dry toilet and excreta treatment device

An excrement and environment-friendly technology, applied in gas treatment, fertilization devices, excretion of fertilizers, etc., can solve the problems of easy accumulation of fermentation products and filling up the fermentation tank, slow natural compost fermentation, incomplete fecal fermentation, etc. The effect of aerobic biochemical degradation reaction speed, shortening treatment period and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

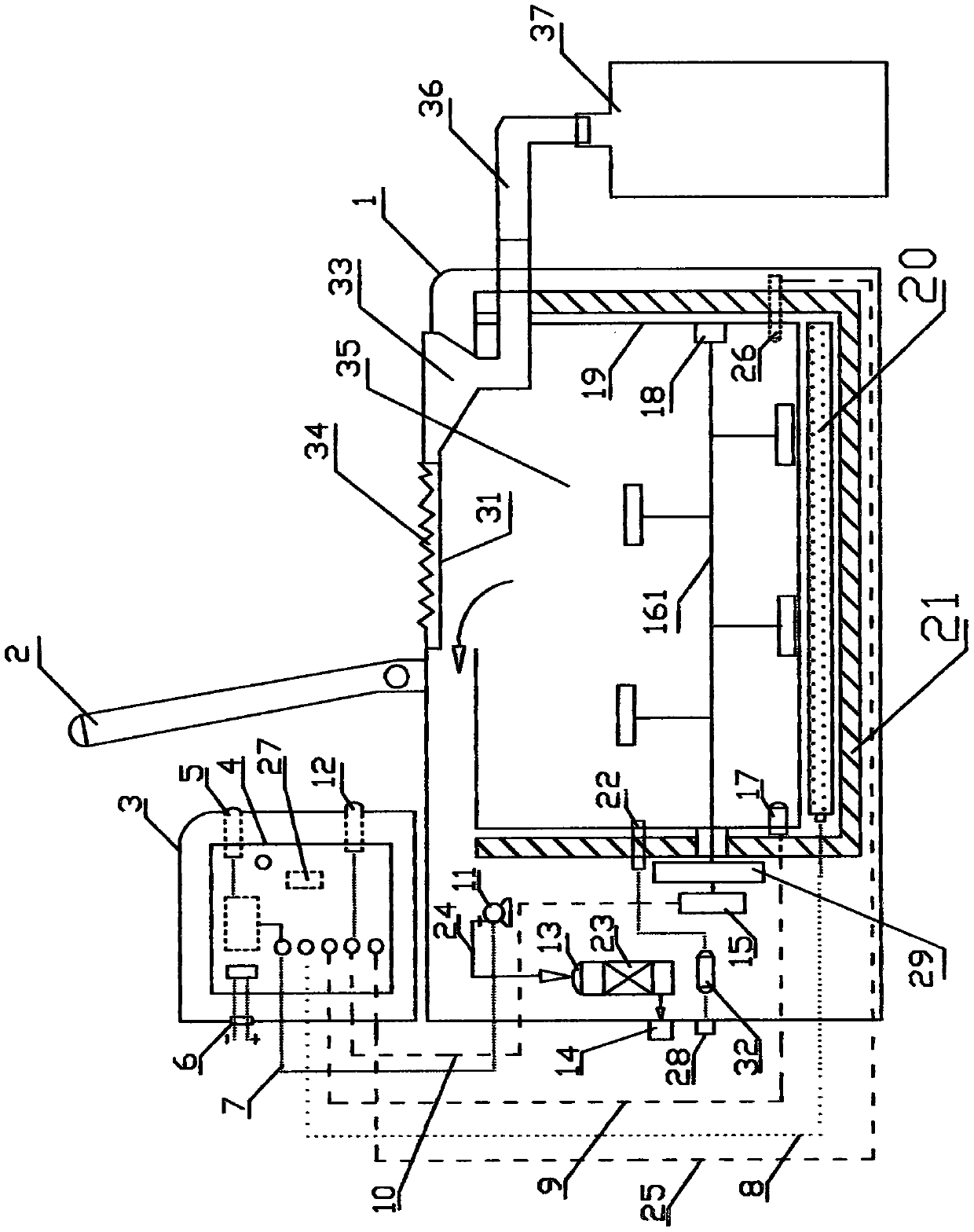

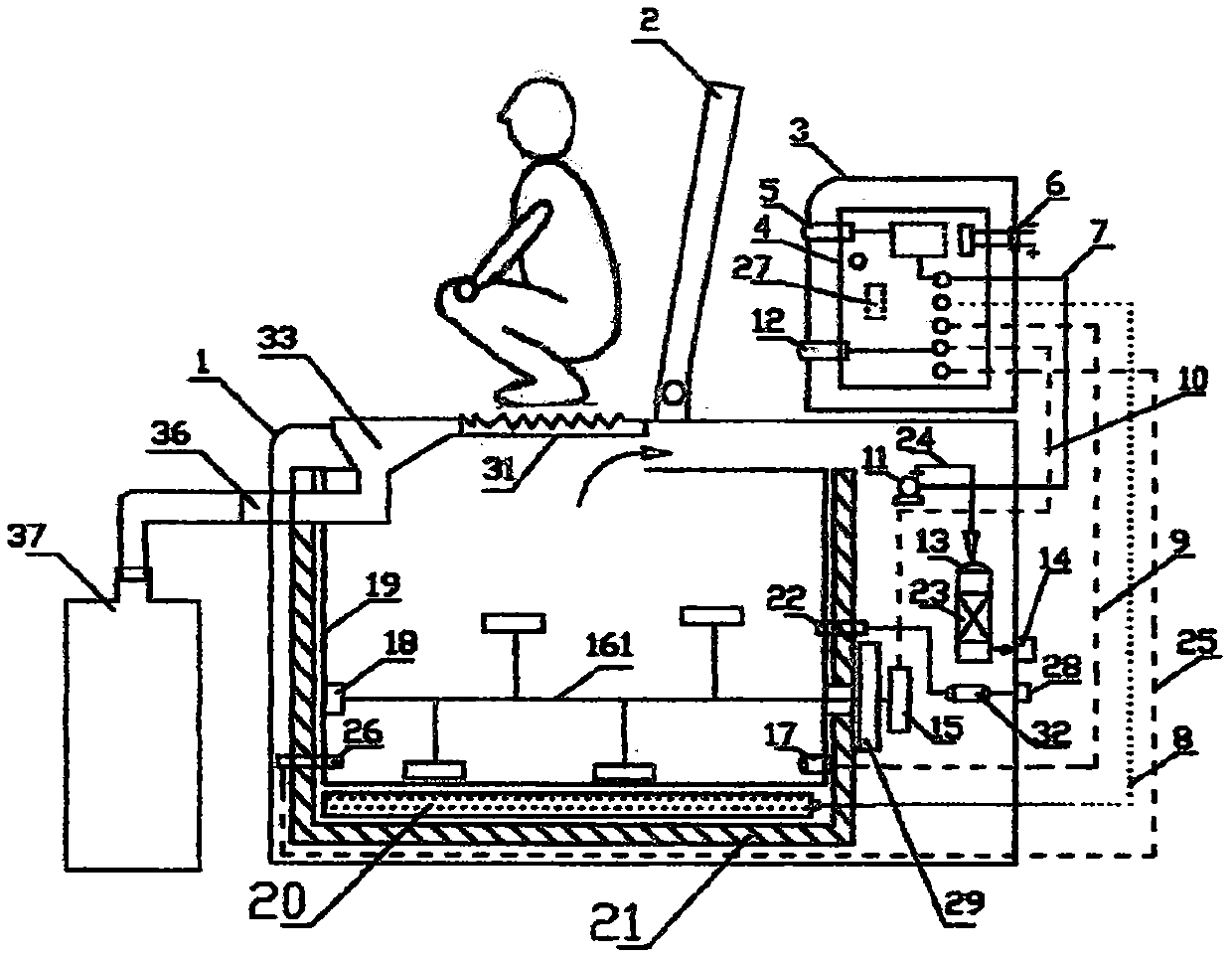

[0046] The present invention uses an aerobic fermentation device, which uses aerobic microorganisms to decompose and convert excrement into carbon dioxide, water and organic fertilizers;

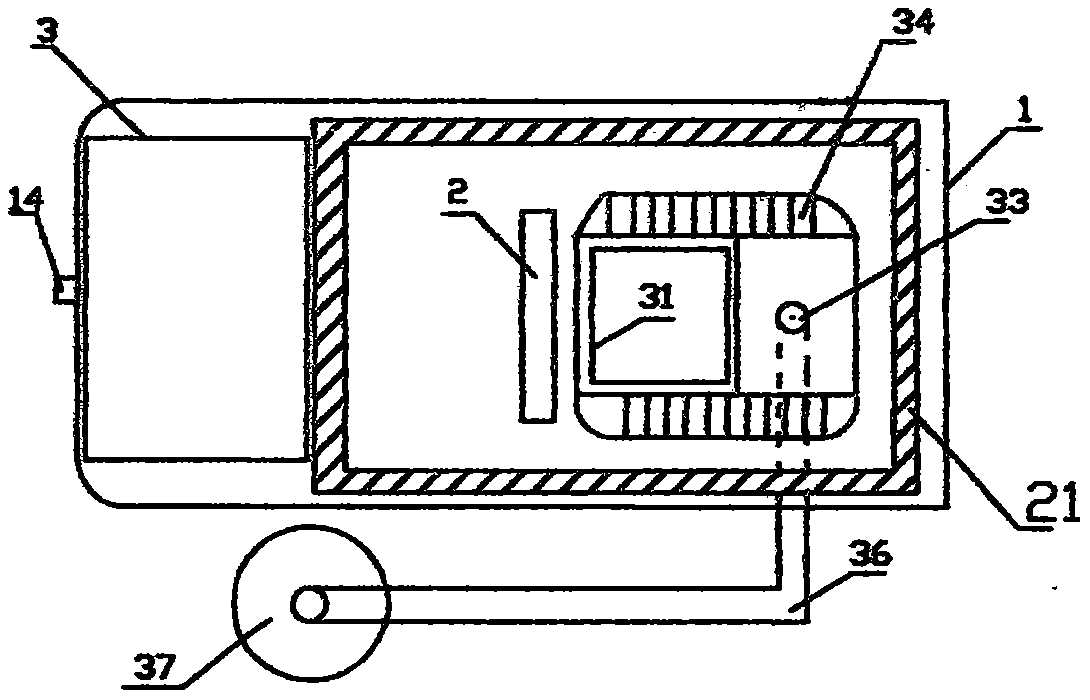

[0047] refer to figure 1 and Figure 5 , the described environment-friendly aqua toilet with urine and feces separation, consists of an aqua toilet housing (1), an excrement treatment device configured in the aqua toilet housing, a squatting pan (34) for separating urine and feces, and a sealing cover plate (2 ), a urine collection bucket (37) and a control box (3) are formed;

[0048] The dry toilet housing (1) is made of metal, wood, fiberglass, plastic, or organic composite material. The top plate of the housing (1) is provided with a squatting pan (34) that separates urine from feces and squats (34). 34) A sealing cover (2) is arranged on the top, and the sealing cover (2) is uncovered to excrete urine, add raw materials or take out the transformed organic fertilizer in the fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com